Our Perspective on Industry 4.0

BCG’s Industry 4.0 consulting embraces a holistic approach: we work across all production sites to ensure that everything from technology infrastructure to governance and competencies are integrated and aligned. Our focus is helping our clients build “factories of the future”—fully digital plants that deploy Industry 4.0 technologies and digital supply chain to achieve results that are sustainable, consistent, and scalable.

What Is Industry 4.0?

Put simply, Industry 4.0 makes factories “smart.” Such technologies as the industrial Internet of Things, artificial intelligence, and cyber-physical systems interact seamlessly, communicating and adjusting continuously. Businesses that fully understand and capture the value of these advantages will be best positioned to take on the challenges that lie ahead.

The Nine Technologies Driving Industry 4.0

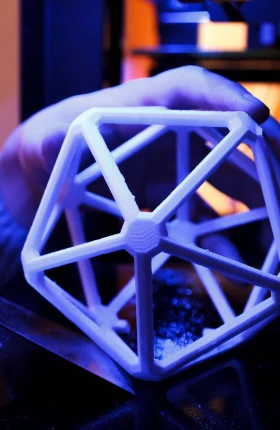

- Additive Manufacturing. The classic example of additive manufacturing is 3D printing. Instead of prototyping individual components, companies can now produce small batches of customized products. The resulting advantages include the speedy manufacturing of complex, lightweight designs.

- Augmented Reality. Augmented reality (AR) systems support a variety of services, such as selecting parts in a warehouse and sending repair instructions over mobile devices. With AR, companies can provide workers with real-time information that improves decision making and work procedures.

- Autonomous Robots. Autonomous robots can interact with one another and work safely side by side with humans. These robots will cost less and have an increasing range of capabilities over time.

- Big Data and Analytics. In an Industry 4.0 context, the collection and comprehensive evaluation of data from many different sources—production equipment and systems as well as enterprise- and customer-management systems—will become table stakes.

- The Cloud. The more production-related initiatives a company undertakes, the more it needs to share data across sites. Meanwhile, cloud technologies continue to get faster and more powerful. Companies will increasingly deploy machine data and analytics to the cloud, thus enabling more data-driven services for production systems.

- Cybersecurity. It’s no surprise that Industry 4.0 boosts increased connectivity and the use of standard communications protocols. As a result, the need to protect critical industrial systems and manufacturing lines from cybersecurity threats rises dramatically. For this reason, secure, reliable communications, together with sophisticated access management for machines and identity verification of users, are essential.

- Horizontal and Vertical System Integration. Industry 4.0 allows companies, departments, functions, and capabilities to become much more cohesive. Cross-company, universal data-integration networks evolve and enable truly automated value chains.

- The Industrial Internet of Things. Industry 4.0 means that more devices are enriched with embedded computing. This process allows devices to communicate and interact both with one another and with more centralized controllers. It also decentralizes analytics and decision making, thus enabling responses in real time.

- Simulation. Simulations are a cornerstone of the industrial revolution 4.0. They’re used extensively in plant operations to leverage real-time data and to mirror the physical world. Done right, these models allow operators to test and optimize settings in numerous variations, thereby driving down machine setup times and increasing quality.

Our Industry 4.0 Offerings

BCG’s Industry 4.0 consulting services take a holistic, sustainable, and scalable approach. We deliver by deploying proprietary tools and methodologies developed in our Innovation Center for Operations infrastructure. These offerings cover every manufacturing domain and comprise advanced manufacturing technologies that are empowered through data progression, storage, and optimization.

We help clients address the full range of issues associated with factories of the future:

- Greenfield. We simulate a flexible-cell manufacturing setup and, using real production data, compare the simulation with other potential configurations.

- Brownfield. We simulate a layout adjustment to identify potential areas to improve production processes or workflow.

- Green. We develop an all-electric logistics concept that reduces a factory’s carbon footprint to meet the Paris agreement. To achieve the Green Factory of the Future, we work address carbon in three ways: avoid, reuse/store, and compensate.

Several of BCG’s proven proprietary tools and methodologies focus on this fourth industrial revolution.

Mobile Labs

BCG can also bring the technologies to you—experience the industrial revolution 4.0 anywhere in the world with interactive workshops, thanks to our mobile labs.

- Our Truck Line lab helps you experiment with implementing Industry 4.0 in discrete manufacturing, focusing on warehouse logistics and assembly efficiency.

- Our Process Line lab simulates candy production, enabling you to visualize the benefits of quality control, material use, and maintenance in process industries. Both provide insight into more than 20 technology use cases, combine Industry 4.0 technologies and lean principles, and offer immersive training.

Proprietary Resources

As a BCG client, you gain access to a variety of our proprietary data collections:

- Our Industry 4.0 Health Check, which assesses a plant’s digital maturity.

- Benchmarks of key metrics in manufacturing and supply chains across major industries.

- Our case study database, which contains reports of how Industry 4.0 technologies have been successfully implemented.

- Our technology-vendor database, which details suppliers by industry to help you select the right one.

Unlocking Value Through Industry 4.0

By partnering with BCG, our clients achieve concrete and quantifiable gains. In an Industry 4.0 consulting engagement with us, these benefits can include:

- Greater Efficiency. Gain 10% to 15% efficiency in the short term and 20% to 40% in the long term.

- Greater Flexibility. Boost your changeover reduction by 20% to 60%.

- Lower Cost. Cut the cost of raw materials by 2% to 5%.

BCG’s Featured Client Work in Industry 4.0

A global manufacturer of food and beverages turned to BCG to improve its overall equipment effectiveness (OEE). BCG used advanced analytics to deliver a 10-point lift in OEE.

A consumer goods company was relocating its production. By working with BCG’s Innovation Center for Operations, the company set up an Industry 4.0 greenfield factory that slashed conversion costs by 13%, enhanced material flow, and optimized warehouse efficiency.

BCG's Latest Insights on Industry 4.0

Meet Our Industry 4.0 Consulting Leaders