Industrial robots—machines that can be automatically controlled and reprogrammed and that can manipulate objects and move along three or more axes—were first introduced in Europe, Japan, and the U.S. in the 1960s. About 1.4 million industrial robots are in use around the world today.

Yet even in many high-cost economies, the use of robots has remained limited in most industries. In Italy, for example, only one-half of 1 percent of tasks have been automated in the chemical and primary-metals industries, though around 14 to 16 percent could be automated today. Adoption rates have also remained surprisingly low in industries that long have been at the forefront of automation. Fewer than 8 percent of tasks in the U.S. transportation-equipment industry are automated, for example, compared with a potential of 53 percent. The global installed base for robots has been growing by around 2 to 3 percent annually for around a decade—roughly in line with growth in manufacturing output.

The use of industrial robots is also highly concentrated. Nearly three-quarters of all robots operate in just four industrial groupings: computers and electronic products; electrical equipment, appliances, and components; transportation equipment; and machinery. What’s more, 80 percent of the robots sold each year are deployed in just five countries: China, Germany, Japan, South Korea, and the U.S. And because robotics systems have historically been so expensive to own and operate, they are found mainly in large factories owned by corporations with big capital budgets.

A number of economic and technical barriers to wider adoption are beginning to fall, however. As a result, a dramatic takeoff in advanced robotics is imminent. We expect that growth in the installed base of robotics will accelerate to around 10 percent annually during the next decade, by which time installations will surpass 4 million. (See Exhibit 1.) Annual shipments of robots will leap from around 200,000 units in 2014 to more than 500,000 by 2025 according to our baseline projection, and to more than 700,000 in a more aggressive scenario. Even so, we project that, by 2025, those installations will represent only about one-quarter of all manufacturing tasks and far less than that amount in other industries and major manufacturing economies. The growth potential over the long term, therefore, should remain immense.

Three major trends are speeding global industries toward an inflection point at which advanced industrial robots will become much more commonplace. That point will be characterized by greater cost-effectiveness for robots when compared with human labor, technological advances that are wiping out barriers to adoption in key sectors, and the arrival of systems that smaller manufacturers can afford and easily use.

Cost and Performance

For many organizations, the biggest reason for not replacing manual labor with robots is purely economic. We believe that most organizations begin to ramp up their investment in automation when the cost of employing human labor rises high enough above the cost of owning and operating robotics systems to make human labor less cost-effective. We have assumed conservatively that this point is reached when the cost of human labor becomes 15 percent higher than the cost of robotics labor. Yet even with the relentless rise in wages around the world, the gap remains wide enough to prevent mass deployment.

The economics of advanced robotics are improving rapidly, however. For example, the total cost of purchasing and deploying a robotics system for spot welding in the U.S. automotive industry plunged from an average of $182,000 in 2005 to $133,000 in 2014 (not adjusted for inflation). By 2025, the total cost is projected to drop by approximately another 22 percent, to around $103,000. The prices of robotics hardware and software, which account for only one-quarter of that total cost, are around 40 percent lower than they were a decade ago. The cost of systems engineering—which includes installing, programming, and integrating a robotics system into a factory—has declined even more. Ten years ago, the average systems-engineering costs of a spot-welding robot amounted to $81,000. Those costs are now down to around $46,000, on average, and are likely to keep dropping for the rest of the decade. The costs of peripheral equipment—such as sensors, displays, and expensive safety structures that protect workers and that together typically cost more than the robots themselves—are plunging as well. (See Exhibit 2.) In fact, safety barriers may not be required at all for many next-generation robots.

At the same time that costs have been declining, the performance of robotics systems has been improving by around 5 percent per year. Taken together, the changes in price and performance for spot welding, for example, have been translating into an annual 8 percent improvement in the cost of robotics. To put this into perspective: an investment of $100,000 today buys a robotics system that is capable of performing more than twice as much work as a robotics system costing the same amount a decade ago. This pace of improvement in price and performance is expected to be sustained for the foreseeable future.

Robotics systems are thus becoming an economically viable alternative to human labor in more and more industries. A human welder today earns around $25 per hour (including benefits), while the equivalent operating cost per hour for a robot is around $8 when installation, maintenance, and the operating costs of all hardware, software, and peripherals are amortized over a five-year depreciation period. In 15 years, that gap will widen even more dramatically. The operating cost per hour for a robot doing similar welding tasks could plunge to as little as $2 when improvements in its performance are factored in. (See Exhibit 3.)

Other industries are quickly approaching inflection points. The U.S. electronics and electrical-equipment manufacturing industries currently deploy about 3,300 industrial robots, many of them relatively basic and designed to perform simple tasks. But manufacturers are in the process of adding more versatile—and more expensive—robots to take on increasingly complex tasks. Today, the cost of a “generic” robotics system—which has a high degree of flexibility and thus can take on many different types of work—is around $28 per hour. By 2020, this cost is projected to fall to less than $20 per hour, which would be below the average human worker’s wage. This will enable a significant increase in the number of tasks that can be automated. We estimate that, as a result, the percentage of tasks handled by advanced robots will rise from 8 percent today to 26 percent by the end of the decade.

Some industries will be slower to adopt. In furniture manufacturing, where tasks remain more difficult to automate, the economic payoff of using robots is still a number of years away. Based on our estimates, the adoption of robots in that industry won’t begin in earnest until 2020; and it will be near the end of the next decade before even 10 percent of tasks are automated.

Technological Advances

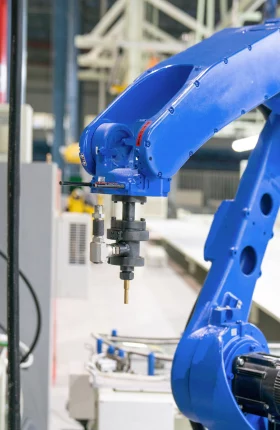

The technical capabilities of most industrial robots today are still quite limited. Traditional robots are rigid: they are fixed in the same location and can handle only objects that are of a uniform size, oriented in a predictable way, and moving at a determined speed. Most can process images and detect features on objects, but they lack the logic capabilities to make decisions about those objects.

What’s more, heavy and expensive safety devices have been required to protect workers from robots in operation. Robots are typically found isolated in the corner of a work environment, performing tasks that are highly repetitive and require consistency and accuracy or tasks that are hazardous to humans. If the robots are mobile, collision avoidance systems are often necessary as well. Such impediments have greatly narrowed robots’ usefulness for many industrial applications.

Thanks to leaps in technology, however, advanced robotics systems can now perform tasks and work in environments that are far less structured. As costs drop, companies can afford to buy robots with arms that rotate freely, giving them more flexibility to handle objects and enabling them to deal with objects whose dimensions, features, and properties vary. Robots also have more sophisticated sensors to see and feel objects and can be more quickly and easily reprogrammed to perform different tasks. Advanced robots are more “intelligent” as well. They can apply logic to make decisions about objects, judge quality, and receive and provide feedback to other parts of a production system through information technology. Special safety barricades are not required for many advanced robots, which means that they can work side-by-side with humans. Even some very low-cost robots can work together with humans to complete their collective tasks.

These capabilities have greatly expanded the utility of robots in a range of industries. Meat processing is one good example. Cutting and trimming meat is very challenging for traditional robots because the pieces of meat come in different shapes, and their properties can vary significantly. One German company has solved this problem with a 3D visual-inspection system that enables advanced robots to trim and cut.

One traditional obstacle to wider robotics use in the fabricated-metals industry has been the difficulty of translating computer-aided-design drawings for complex jobs, such as grinding a gear to remove burrs and other defects, into instructions for a robot. Computer-aided-manufacturing software tools such as Robotmaster, by Jabez Technologies—which integrates robot programming, simulation, and code generation—make doing so much easier.

Electronics manufacturing has presented special challenges for automation. Robots are often used to place components onto flat surfaces, such as circuit boards, for example. But it has been difficult to design a robot that can install very small parts, such as connectors, at odd angles with high degrees of precision and at very high speeds—the abilities necessary to build an automotive battery, for instance. As a result, the industry remains quite labor intensive. But there is progress: Japanese robotics giant Fanuc has demonstrated a high-speed robot that rotates along six axes and has the dexterity to perform such tasks.

Most advanced robots can be quickly reprogrammed for new jobs, giving manufacturers the flexibility to produce small batches of customized products without additional capital investment. Wiring accessory manufacturer ABB Elektro-Praga, for example, needed to increase throughput at its factory in the Czech Republic. The company wanted machines that could pick parts from a bin and orient them properly for assembly, a task that conventional robots could not perform at high speed and with precision. It also wanted robots that could work on different product configurations with minimal adjustment. ABB Elektro-Praga installed several of ABB’s IRB 140 robots on a new assembly line linked to a vision system equipped with digital cameras. The vision system enables the robots to orient parts and place them at a cycle time of 2.3 seconds per electrical socket, for example. It takes only 10 minutes to adjust the system to pick and place parts for different products, which are often changed up to 30 times each week. As a result of the new system, ABB Elektro-Praga says that it has boosted throughput of each shift by a factor of about nine. Only one worker is required to oversee the entire robotics assembly line.

Accessibility for Small Manufacturers

The steady improvements in cost, performance, and functionality of robotics systems are driving another force in the next manufacturing revolution: the wider adoption of robots by small and midsize manufacturers. Until recently, such systems have been prohibitively expensive and overly complex for enterprises with limited capital budgets and engineering resources.

The new generation of innovative systems is putting robots within the financial reach of small enterprises. Universal Robots, for example, markets the UR5, an industrial robot that is designed for material handling and assembly and has a base price of $34,000. Its two arms rotate along six axes, resulting in remarkable flexibility for a machine of that price. By our analysis, the total cost of installing such low-cost generic robots can range from $50,000 to $100,000 when accounting for associated costs and the project management required to make it all come together. Universal says that the average cost of installing the UR5 is around $50,000. Two of Rethink Robotics’ robots—Baxter and the company’s high-performance robot, Sawyer—are designed for precision applications, such as machine tending and circuit board testing. Each costs around $40,000, including accessories, warranties, and installation. Because they can be redeployed quickly and easily across multiple product lines, the Rethink robots can be used in high-mix environments that are impractical for conventional industrial robots.

In addition to their low cost, the UR5 and Rethink robots can easily be moved by hand and repurposed by workers with no programming experience. They can safely work next to humans on the same production line without expensive barricades or other protective equipment, eliminating a major cost associated with conventional industrial robots.

RSS Manufacturing & Phylrich—a Costa Mesa, California, manufacturer of high-end plumbing fixtures and faucets with 72 employees—illustrates how such machines can pay off for even small and midsize manufacturers. The company wanted an inexpensive automation solution that could easily be moved to perform different production tasks in the factory, so it purchased a UR5. One of the robot’s first jobs was to help fill an order to make 700 valves a month. With its existing computer-numerical-control milling machine, the company could produce only 400 valves a month with two work shifts. By using the UR5 robotic arm to feed parts into and remove them from the milling machine around the clock, RSS was able to fill the order in 11 days while increasing production capacity by 30 percent. By using the UR5 for another job—to feed tubes into a bending machine—the company was able to produce 1,500 pieces in four hours, a task that otherwise would have taken two to three days. The company estimates that it achieved a return on its investment in a few months.

As economic and technical barriers continue to fall, robots are becoming accessible for more companies. The production efficiencies will spread beyond individual factories through entire supply chains, industries, and national economies.