For several decades, manufacturers have used lean principles and tools to reduce operational complexity and improve productivity. The lean approach provides the foundation for operational excellence by standardizing processes, instilling a culture of continuous improvement, and empowering workers on the shop floor. However, given the increasing complexity of operations, many companies have found that lean management by itself is not sufficient to address their operational challenges. Recently, a set of advanced digital technologies known as Industry 4.0 has emerged to offer new approaches for dealing with complexity and improving productivity. By deploying the right combination of technologies, manufacturers can boost speed, efficiency, and coordination and even facilitate self-managing factory operations. (See the sidebar “The Basics of Lean Management and Industry 4.0.”)

The Basics of Lean Management and Industry 4.0

Both lean management and Industry 4.0 support the objectives of operational excellence, but they apply different types of tools to achieve these goals.

Lean Management. This approach reduces complexity and cost by eliminating waste and non-value-adding activities throughout a process or value chain. It provides techniques for involving all employees in continuously reviewing and improving efficiency. The approach is built on such management techniques as waste reduction, takt time planning, and standardized processes. A variety of tools are applied to achieve lean objectives: value stream mapping identifies waste and critical process steps, single-minute exchange of dies reduces equipment downtime that results from tool changeovers, visual controls help operators identify the right times to replenish material or adjust equipment, and preventive maintenance reduces the number of breakdowns by proactively maintaining and controlling equipment at fixed intervals.

Industry 4.0. The fourth wave of technological advancement in manufacturing is powered by nine foundational technologies: additive manufacturing, advanced robotics, augmented reality, big data and analytics, cloud computing, cyber security, horizontal and vertical system integration, the industrial internet, and simulation. Sensors, machines, work pieces, and IT systems are connected along a value chain that extends beyond a single enterprise. These connected systems can interact and analyze data to predict failure, reconfigure themselves, and adapt to change. Manufacturers can reach new levels of operational performance. They can, for example, advance from preventive to predictive maintenance, which means that maintenance tasks are performed only when necessary.

Industry 4.0 also allows companies to share the benefits of automation technology more broadly within the organization by, for example, equipping and training line workers to receive and apply real-time information about their machinery. By increasing transparency, improving predictability, and, ultimately, allowing for self-controlled systems, Industry 4.0 promotes faster, more flexible, and more efficient processes. Manufacturers can apply these benefits to achieving the broader objectives: producing higher-quality goods and reducing costs. (See Industry 4.0: The Future of Productivity and Growth in Manufacturing Industries, BCG Focus, April 2015.)

Manufacturers seeking to optimize their operations need to understand the interplay between traditional lean management and Industry 4.0. Supporting hundreds of operational excellence programs in recent years, we have seen companies generate valuable synergies by implementing lean management and Industry 4.0 holistically, rather than independently or sequentially. Indeed, in most cases, the integrated application of lean management and Industry 4.0—which we call Lean Industry 4.0—is the most effective way to reach the next level of operational excellence.

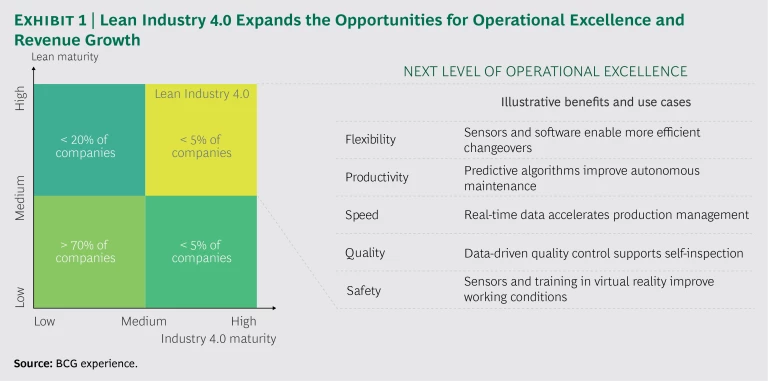

Manufacturers that have successfully deployed Lean Industry 4.0 can reduce conversion costs by as much as 40% in five to ten years—considerably better than the reductions captured by best-in-class independent deployment of lean or Industry 4.0. The higher cost reductions are, in many cases, achieved with technologies that improve plant processes and structures by, for example, optimizing layouts. (See The Factory of the Future , BCG Focus, December 2016.) However, fewer than 5% of the manufacturing companies that we have observed have reached a high level of maturity in Lean Industry 4.0. (See Exhibit 1.)

To capture the greatest benefits, a manufacturer must tailor the application of Lean Industry 4.0 to address its specific challenges along the supply chain and at the plant level.

Using Integrated Solutions to Achieve Significant Benefits

A recent global survey by The Boston Consulting Group found that leading industrial companies recognize the importance of both lean management and digitalization in their long-term planning. In a survey of more than 750 production managers, 97% of automotive respondents said that lean management would be highly relevant in 2030, compared with 70% who said that it is important today. Among these respondents, 70% said that plant digitalization would be highly relevant in 2030, compared with 13% who said that it is important today.

Although the need to implement both lean management and Industry 4.0 is clear to many manufacturers, they are uncertain about how to combine the two for maximum benefit. Our experience has shown that it is essential that companies think of Lean Industry 4.0 in terms of use cases—the optimal combination of lean tools and digital technologies. They must then carefully select which use cases to implement in order to most effectively address a specific pain point.

By using integrated Lean Industry 4.0 solutions to address pain points, manufacturers can achieve a variety of benefits. We present a selection of five benefits and highlight an exemplary use case for achieving each one.

Flexibility: Sensors and Software Facilitate More Efficient Changeovers

Manufacturers want flexible operations that allow them to use one production line to make multiple products. However, the benefits of flexibility are hard to capture because time-consuming changeovers are required to prepare machinery to manufacture different products. By implementing lean tools, such as single-minute exchange of dies, manufacturers can remove non-value-adding activities from the changeover, thus significantly accelerating the process. Industry 4.0 technologies support these efforts. New sensors and software make it possible for machines to automatically identify products and load the appropriate program and tools without manual intervention. Because the changeover is automated, operators can focus on performing value-adding activities.

For example, a manufacturer implemented a tracking system that uses radio frequency identification tags on individual work pieces to classify each product. Assembly stations use the system to identify the product that will be produced next and to set tools to the right parameters. With no operator intervention, the production line can change over instantly.

Productivity: Predictive Algorithms Improve Automous Maintenance

In many manufacturing industries, equipment breakdowns and failures lead to high inventory levels and low productivity. Companies can use lean methods, such as autonomous or preventive maintenance, to boost overall equipment effectiveness (OEE). To use autonomous maintenance, for example, companies assign responsibility for specific do-it-yourself maintenance activities to their operators, significantly reducing the downtime required to correct minor issues. Leading manufacturers are making the most of these lean methods by using advanced analytics algorithms and machine-learning techniques to analyze the huge amounts of data collected by sensors. The output identifies the potential for breakdowns before they occur. Such predictive insights prepare operators to perform autonomous maintenance at the optimal time, thereby reducing disruptions and minimizing unnecessary downtime and replacement costs.

An aluminum producer uses mobile devices to provide its maintenance teams with real-time information on equipment performance, including where breakdowns are occurring or about to happen and their underlying causes. The teams use the devices also to access maintenance documents (such as machine plans) and to receive remote guidance on the tools required for making repairs.

In addition to improving maintenance productivity, the greater transparency afforded by big data and analytics generally adds to the effectiveness of lean tools and promotes continuous improvement. (See the sidebar “A Food Production Plant Uses Big Data to Enhance Lean Levers.”).

A Food Production Plant Uses Big Data to Enhance Lean Levers

For a variety of reasons, including equipment breakdowns, inadequate supplies and staffing, and quality issues, a European food production plant was failing to meet output targets. Management struggled to understand the root causes of these problems because there was no transparency into performance at the line and plant levels. Performance data was available, but the company had not used advanced analytics and benchmarking to gain insights. In the context of a full-scale digital operations transformation, BCG worked with the company to implement a data-centered approach that identifies the most valuable lean improvement levers to apply. (See the exhibit.)

First, management needed to gain transparency into the plant’s performance and the root causes of the problems. To gather information, the company installed a preconfigured sensor system developed by BCG. The system measures, among many other parameters, the temperature and humidity in the plant and tracks the number of parts produced. Installation of the system was completed in less than a day. At any time of day or night, plant personnel were able to use laptops and mobile devices to access real-time production data related to OEE and the root causes of stoppages. Data for five production lines was collected continuously for ten weeks.

Next, BCG worked with management to improve the predictability of production performance. This included performing a big data analysis that identified patterns of equipment failures. With the results, the company was able to apply predictive maintenance, significantly increasing mean time between failures. By comparing internal production lines and comparing their performance with external benchmarks, management learned to understand performance losses in detail and to differentiate among loss types, such as microstoppages and deviations from benchmarks for cycle times and changeover times. The analysis also generated insights into maximum equipment speeds and the optimal sequence for changeovers.

Last, management applied the results to its move toward self-optimizing systems that largely control themselves by automatically adjusting parameters such as temperature, which was identified as having significant impact on product quality.

Overall, the company identified and prioritized Lean Industry 4.0 measures that allowed it to improve OEE by 8 to 10 percentage points. The improvement measures included defining new standard speeds, reducing unplanned stoppages, optimizing line staffing, increasing machine availability, reducing changeover times, and limiting material waste. BCG implemented the analytics infrastructure required to create full transparency and worked with management to develop a clear roadmap toward the achievement of sustainable operational improvements. BCG also provided a toolkit and database for benchmarking the performance of different lines and other plants.

Speed: Real-Time Data Accelerates Production Management

Manufacturers struggle with the complexity of production planning as they seek to increase the number of product variants while reducing batch sizes. Operators use shop floor management and other daily routines—core elements of lean management—to react daily to deviations in production, identify issues, and update employees on required changes to production plans. However, these tools are not effective for planning and controlling production in real time.

By applying certain algorithms, manufacturers can overcome the challenges of managing production in real time. Two key elements in the effective use of algorithms are a centralized “control tower” that collects data and directs all material movement inside and outside the factory and a horizontally integrated value chain. For example, after first improving the reliability and stability of its production process, a home appliance manufacturer created an algorithm that generates each day’s ideal production plans on the basis of orders, capacity utilization, and inventories. A control tower consolidates the data collected from various sources in an integrated value chain and feeds it into the algorithm. With the output, the company can select plans in real time, using such criteria as efficiency, lead time, and customer priority.

Real-time data also helps enhance and accelerate continuous-improvement efforts. Line staff and managers can use real-time data to identify the root causes of performance issues and speed the validation of improvement measures, thereby permitting a faster rollout of the measures throughout the plant.

Companies can use real-time monitoring daily to shorten reaction and response times. A supplier of C-parts (for example, screws, nuts, and washers) has attached camera systems to the parts containers in its customers’ warehouses and production lines. The systems trigger the automatic replenishment of parts when inventory falls to a predetermined minimum, and the manufacturer captures the benefits of just-in-time restocking.

Quality: Data-Driven Quality Control Supports Self-Inspection

Production capacity is wasted if products do not meet specifications. Even worse, if a manufacturer ships poor-quality products to customers, they will incur higher costs and likely lose trust in that supplier. Many lean management tools—such as self-inspection, poka yoke, and jidoka—have been developed to reduce the likelihood of errors and increase the rate and speed of error detection. For example, our analysis shows that self-inspections improve the process of providing feedback to engineers and operators, thereby accelerating error detection and reducing the number of defects by 50% to 70%. However, to achieve zero defects, manufacturers must support self-inspections by using a data-driven analytics approach to identify the root causes of errors. Industry 4.0 technologies allow such support by providing reliable context data and the ability to conduct detailed tracking. The analysis of errors is enhanced through, for example, camera-based visual inspection, correlation models, and real-time monitoring of process parameters.

An automotive supplier was able to improve its quality control significantly by using an integrated Lean Industry 4.0 approach. First, the supplier implemented a self-inspection process, giving workers responsibility for performing visual quality checks of their output.

Next, the supplier implemented a camera system that can detect surface defects. The camera, linked to the quality system, automatically creates failure reports and detailed analytics, reducing the visual-inspection and manual-reporting time by 70%. By analyzing the inspection system data in real time, operators can make sure that the output of the production process adheres to high quality standards.

Safety: Sensors and Training In Virtual Reality Improve Working Conditions

Safety is among the most important production KPIs. To ensure operator safety, one lean approach uses signs to tell operators where they may walk. Another lean approach uses detailed tracking of incidents and near misses to identify areas for improvement. Companies can use low-cost wireless sensors to improve the effectiveness of such efforts. For example, they can fit operators with sensors that will alert them to the presence of dangerous gases or the possibility of a clash with nearby forklifts or trucks.

Companies can further improve safety by using virtual reality to train workers. Offsite training in a virtual environment is more efficient and effective than training in an actual work environment, and the approach appeals to the younger generation of workers. Seeking to reduce the high accident rate among new hires, a provider of service rigs developed immersive-training sessions in which workers practice often-dangerous tasks in a virtual simulation of the work site.

Quantifying the Improvement Potential

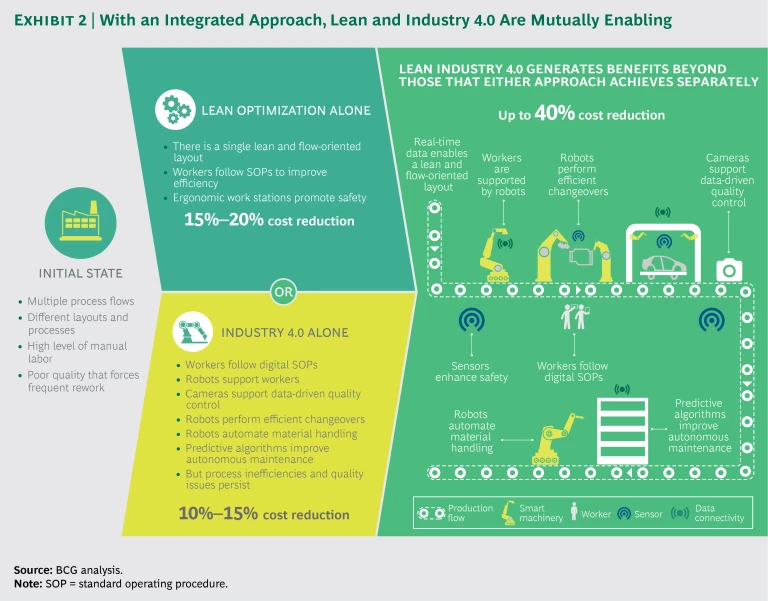

The improvement potential of an integrated approach is significant. We have found that when either approach—lean initiatives or Industry 4.0—is applied alone, it can reduce conversion costs by approximately 15%. However, in our experience, companies that use the integrated Lean Industry 4.0 approach can reduce conversion costs by as much as 40%. (See Exhibit 2.) Companies have also used the integrated approach to reduce costs associated with poor quality by 20% and work-in-process inventory by 30%.

Because the integrated approach allows lean management and Industry 4.0 to be mutually enabling, its improvement potential is greater than the sum of the improvements achieved by either approach independently. Mutual enablement promotes benefits beyond the typical limits of either of the two approaches. For example, using sensors and data to provide full transparency into bottlenecks allows the company to sharpen the focus of its lean efforts to improve OEE.

In BCG’s experience, the payback time for use cases that are properly implemented is less than three years. However, we often see investments that exceed required levels. Because the benefits derived from Lean Industry 4.0 correlate with the efficiency of the underlying process, the company must avoid “automating waste” in the form of processes that include non-value-adding or nonstandardized activities. If a company invests in deploying robots before processes have been optimized, the robots will perform non-value-adding activities—such as unnecessary movements—that reduce the deployment’s financial return.

Getting Started with Lean Industry 4.0

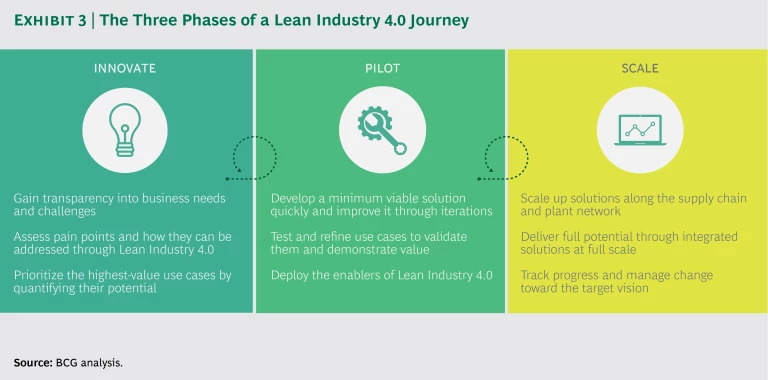

A structured approach is essential to the successful implementation of Lean Industry 4.0 and achieving a higher level of operational excellence. The Lean Industry 4.0 journey comprises three main phases: innovate, pilot, and scale. (See Exhibit 3.)

Innovate. To initiate innovation, the company must gain transparency into its business needs and challenges, the improvement opportunities, and the extent to which the enablers of Lean Industry 4.0 are in place. BCG has developed a comprehensive assessment that clarifies the current state of implementation and identifies the priorities for improvement. (See the sidebar “BCG’s Lean Industry 4.0 Assessment.”)

BCG’s Lean Industry 4.0 Assessment

The Lean Industry 4.0 assessment developed by BCG covers five topics.

Business Needs and Challenges. To provide the context for implementing Lean Industry 4.0, the assessment begins with achieving an understanding of the company’s business needs and challenges. The most important needs and challenges typically evolve over time in response to changes in industry and customer requirements and have implications for the end-to-end supply chain and production.

Applying this understanding, a company can set clear top-down ambitions for its supply chain and its factories’ long-term development. For example, automotive companies must respond to a variety of market developments, including self-driving vehicles, e-mobility, shorter innovation cycles, and the sharing economy.

These trends magnify the complexity of an OEM’s product portfolio and make it harder to predict customer demand, which, in turn, heightens the need for flexibility in production.

Consider an OEM that plans to begin manufacturing electric cars. Because production requirements of electric cars are different from those of gasoline-powered cars, the OEM must either build new production lines or find ways to adapt its existing conveyor-based systems.

Operations Improvements. Next, we assess the major pain points within each operations function and determine how these can be addressed through the integrated application of lean management and Industry 4.0. To use Lean Industry 4.0 to promote operational excellence, companies must make improvements to operations functions across the entire value chain—including procurement, engineering, manufacturing, maintenance, quality, and logistics.

Using a holistic approach, operations leaders can ensure that each function contributes to the improvements. Success requires determining how each function can best support the company in addressing the identified business needs and how functions can work together, end to end, to support superior value creation.

Performance Management. It is critical to determine which specific aspects of performance should be measured. The metrics allow the company to improve operations on the basis of facts and KPIs and to track progress toward the target vision.

Among other benefits, sensors give the line staff significantly more real-time performance data, which can be used to manage performance on the shop floor and enhance the speed and effectiveness of product engineering. Additionally, the real-time visualization of KPIs enables the staff to make immediate corrections to the production process.

People Management. The assessment examines the people-related aspects of Lean Industry 4.0, determining, for example, which traditional and immersive training programs to put in place and the ways that technology can help improve collaboration among employees.

With the implementation of Lean Industry 4.0, the development and training of line workers gains additional importance because these employees need to be prepared for the new ways of working and interacting with technology. For example, line workers, rather than engineers, must be ready to train the collaborative robots that work with them.

Lean Industry 4.0 Foundations. It’s critical to make sure that the foundations for Lean Industry 4.0 implementation—such as the strategy, roadmap, governance model, IT infrastructure, and data security—are in place.

For example, an IT maturity health check assesses the current state of data integration, system interoperability, and vertical and horizontal connectivity. Furthermore, it examines the extent to which existing data is used to optimize production processes. The company must also define its strategy and ensure that the implementation roadmap is designed to realize the strategic vision.

The assessment results are benchmarked to compare progress with that of other plants, the industry average, and peer groups. To support the assessment, BCG has developed a mobile app that makes the results available to plant personnel immediately, allowing them to compare their results with those of others in the network and with industry benchmarks.

During this phase, it is critical that operations managers and executives gain firsthand experience so that they understand the state of the art in Lean Industry 4.0. BCG supports these efforts through its Innovation Center for Operations. The ICO provides access to model factories and mobile labs where managers and executives can try out new technologies and gain insights into their company’s pain points and opportunities.

To deepen their understanding of how Lean Industry 4.0 could help them, executives and managers of an industrial goods company participated in interactive workshops in BCG’s mobile labs. Participating in several rounds of hands-on simulations of a production environment, the company leaders saw how use cases can improve processes and performance. This experience helped make the principles and benefits of Lean Industry 4.0 more accessible and tangible.

Over the course of the simulation rounds, the BCG team introduced participants to Lean Industry 4.0 tools that address the pain points observed in their processes. Standard production KPIs, such as OEE and production costs, were tracked so that participants could see the ways that implementing each use case improves performance. Between rounds, experts enriched the learning experience by providing detailed discussions of the relevant Lean Industry 4.0 principles, reviewing the simulation results, and introducing participants to selected Lean Industry 4.0 use cases, such as the following:

- Connecting smart devices on the shop floor through Industry 4.0 gateways that make it possible to share data and information

- Combining digital standard operating procedures with cloud technology and augmented-reality technology to improve operators’ productivity

- Using real-time KPI tracking and digital performance boards to accelerate response times

- Integrating 3D printing technology to produce spare parts

Once a company’s participants have identified the potential use cases, they prioritize them on the basis of their value, quantifying their potential impact and developing a business case for investment so that they use only those that are financially viable. They can then establish a target for the end state and develop a roadmap for achieving it.

Pilot. To apply the insights gained, the company first tests solutions in a specific part of the supply chain or plant. The objective of each pilot is to develop a minimum viable solution quickly and then improve it through iterations using agile development methods. By implementing an initial set of use cases, the company leaders can validate the approach and showcase the opportunities for value creation. At the same time, the company should deploy all relevant enablers for Lean Industry 4.0.

Scale. Solutions that have been successfully tested and refined in pilots are ready for launch at scale throughout the supply chain and plant. At this point, the company should conduct the rollout in a logical sequence that allows for integrating solutions effectively when deployed at full scale. Progress toward the target state should be tracked rigorously.

If they aim to reach the highest level of operational excellence, companies cannot rely solely on either lean management or Industry 4.0. Nor should they implement one technique without the other. Lean tools are essential for unlocking the potential of Industry 4.0 and preventing the automation of waste. New digital technologies are essential for reaching higher levels of impact from lean initiatives. To achieve the biggest payoff, a company must design innovative ways to combine lean tools and Industry 4.0. Manufacturers that master the ability to apply Lean Industry 4.0 will be the operational excellence champions in the years ahead.