Imagine that you could see the risks in a complex, interconnected supply chain weeks in advance, enabling you to pinpoint bottlenecks in the system and impediments to fulfilling your promises to customers. Modeling with a digital twin makes this possible. By allowing a company to achieve full control of the supply chain system, digital twins confer benefits beyond the end-to-end visibility provided by control towers and the predictive insights generated by planning models such as demand forecasting. (See Exhibit 1.)

A digital twin is a virtual supply chain replica that represents hundreds of assets, warehouses, logistics and material flows, and inventory positions. Using advanced analytics and artificial intelligence (AI), the digital twin simulates the supply chain’s performance, including all the complexity that drives value loss and risks. It identifies where volatility and uncertainty exist, as well as where optimization is possible. A digital twin also enables scenario planning, so that a company can make decisions on the basis of business needs (for example, balancing service levels with inventory needs and costs) rather than merely resolving issues as they arise. By allowing human decision makers to augment their experience and judgment with data-driven, forward-looking insights, digital twins help realize the vision of The Bionic Company ”

The full control enabled by a digital twin allows a company to anticipate risks and make critical optimization decisions far sooner than previously possible. Early implementers have captured a variety of benefits, including sustainable inventory reductions of up to 5%, capex reductions of up to 10% (through better resource planning and investment decisions), and EBITDA improvements of 1 to 3 percentage points. They have also achieved higher throughput and enhanced service levels. To capture such benefits, a company must identify the core business needs to address. Importantly, it must also transform its organizational environment and business processes so that it can rapidly pursue the opportunities. Technology implementation is only a small part of the total effort required.

Early implementers have captured a variety of benefits, including capex reductions of up to 10%.

The Challenges of Managing Complexity

Complex supply chains are common in process industries (such as chemicals, steel, and mining) and in industries with interconnected production and distribution networks (such as oil and gas). In these industries, a single company’s supply chain often comprises more than 1,000 assets, warehouses, and logistics flows. This complexity leads to compromises and lost value—for example, excess inventory and lost production time at critical assets. Predicting bottlenecks in the supply chain, managing inventory buffers, and maintaining required capacity are especially challenging.

The root causes of these challenges include the following:

- Residual uncertainty and variability of demand, even after advanced demand forecasting.

- Uncertainty and volatility of supply. This pertains to goods and services from suppliers as well as internal production capabilities.

- Frequently long lead times for receiving materials from global suppliers or for shipping goods to customers, caused by the geographic span of today’s supply chains. The broad span of networks also lengthens the lead times required in taking mitigation actions.

- Interconnected constraints, such as warehousing and logistics limitations, stock positions, and product portfolio requirements.

- Costs associated with the options available to react to changes. Such options include changing production locations or supply routes, buying additional capacity or supplies, balancing stock, and switching between transportation modes. Each option comes with a price tag or risk.

Better Decision Making Across Multiple Horizons

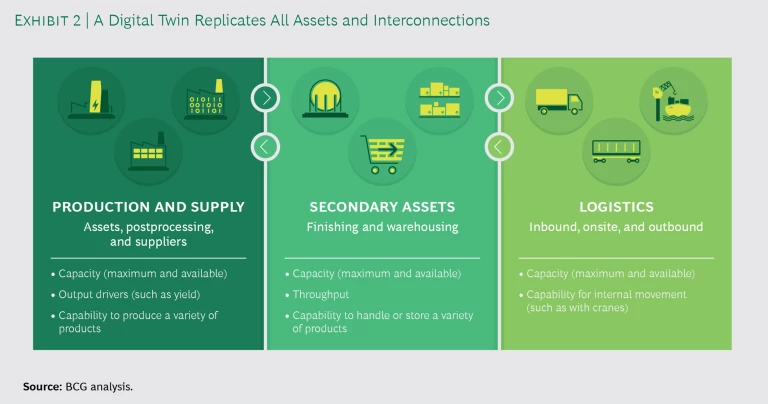

Digital twins help companies address these challenges by simulating all assets and interconnections in a complex supply chain. (See Exhibit 2.)

A company can apply the insights to augment decision making across multiple planning horizons:

- Short-Term Planning and Execution. Because a digital twin can identify execution risks early, a company can mitigate risks rather than manage crises. This allows the company to reduce the idle time of bottleneck assets and to improve inventory positions.

- Sales and Operations Planning. The digital twin can optimize sales and operations planning (S&OP) by simulating the execution of a specific plan, highlighting risks and opportunities, and feeding the insights back into the planning process. This allows the company to minimize the losses that arise from misalignment of plans and system constraints, including latent bottlenecks. The insights also allow the company to better align maintenance plans and inventory buildups with market demand.

- Longer-Term Planning. A company can improve the efficiency of capex and optimize the setup of the overall supply chain system by understanding where the most significant structural bottlenecks exist and how much additional capacity is needed.

A leading process industries company implemented a digital twin to simulate an interconnected supply chain system that spanned more than 100 primary assets and more than 1,000 other elements (such as warehouses and logistics flows) in multiple countries. The digital twin uses inputs from advanced analytics-based demand forecasting, capacity planning, and S&OP.

The company leveraged a cloud-based data platform and built automated data pipelines to connect the platform to all data sources relevant to the digital twin modeling. It then used open-source programming languages to develop the advanced analytics and AI models, as well as the interface for end-user access to the analytics insights. The company completed the implementation within six months.

Management is now able to see anticipated risks in a fully integrated dashboard, conduct in-depth analyses, and select among the mitigation actions proposed by the digital twin. For example, it can anticipate risks, such as warehouse congestion, 12 weeks in advance and take steps to avoid asset standstills. It can also apply the insights to improve decision making, such as in determining which assets to upgrade so that it can better manage its increasingly complex order book and in deciding how to better align its sales plans with the capabilities of its asset network.

Digital twins allow companies to replace crisis management with mitigation actions.

Getting Started and Sustaining the Benefits

As for any technology deployment, the effort to implement a digital twin needs to be led by the business. It is critical that companies clearly understand the value potential and the opportunities to gain competitive advantage. For example, by better understanding and protecting bottleneck assets in the supply chain, a company can increase throughput, improve service levels, and react faster to changes in its sales portfolio.

To create sustainable change, companies must address three enablers from the start:

- Changing processes so that they can effectively use the new insights

- Building up the required capabilities and changing the way of working

- Leveraging a

data and digital platform

in order to release data from core IT systems and quickly build analytics-based minimum viable products (MVPs)

The third enabler introduces technical capabilities that are new to many companies. Companies typically sit on huge amounts of data. However, such data is spread across multiple source systems, encapsulated in legacy IT solutions, and not curated. As a result, it is extremely difficult and costly for companies to extract value from it. A company must overcome these constraints in order to rapidly implement a digital twin. This requires an approach that is radically different from traditional data architecture blueprints: a data and digital platform that connects to all relevant legacy systems. The platform provides data access to all analytics and business teams. A company also needs a proper data governance framework and process to ensure the right level of data quality.

With the appropriate platform and governance in place, a company can implement the digital twin following an agile approach: quickly develop and deploy an MVP to accelerate value creation, and then refine the MVP over time to make it more robust and increase its functionality.

On the journey to a data-driven supply chain, control towers and predictive planning represent the first steps—the table stakes for companies with complex networks. Through the use of advanced simulation techniques and AI-based decision making, digital twins enable entirely new levels of visibility and predictive insights. The first companies to deploy digital twins of their supply chains have already gained impressive levels of control over their complex, interconnected systems—allowing them to identify risks much sooner than previously possible and replace crisis management with mitigation actions. The time has come for companies to move beyond snapshots of current activity and static forecasts to capture the benefits of full control.