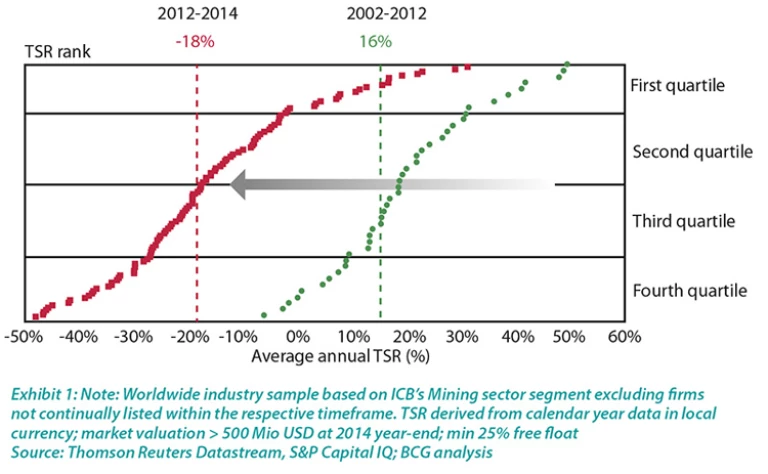

The mining industry faces a sobering challenge. In The Boston Consulting Group’s study of 42 mining companies from around the world, the average annual total shareholder return (TSR) for the organizations in our study was 16 percent from 2002 through 2012 but dropped to negative 18 percent from 2012 through 2014.

This change points to considerable destruction of shareholder value by the sector during these later years. (See Exhibit 1.)

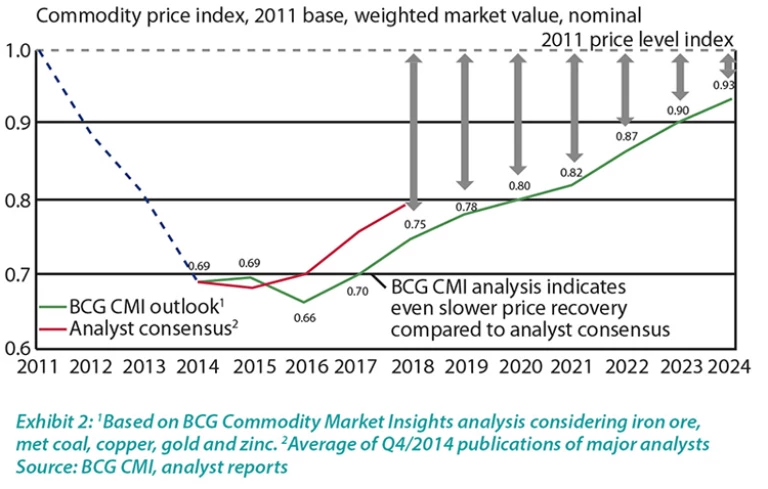

Plummeting industrial commodity prices are partially to blame. From 2009 through 2014, prices fell by an average of 5 percent per year, owing to slowing growth in demand and emerging overcapacity. BCG expects prices to recover slowly, suggesting continued hardship for mining companies. (See Exhibit 2.) In the same period, production costs rose at a compound annual growth rate of 11 percent.

The resulting TSR decline has industry executives shifting their attention away from investment-heavy greenfield expansion toward strategies for extracting greater productivity from existing operations.

The Productivity Challenge

But driving productivity in mining isn’t easy. Mining companies that launch productivity-improvement efforts seldom score meaningful successes. If they do, they have difficulty sustaining those gains—for numerous reasons.

For one thing, many companies fail to align improvement efforts behind their business strategy or ensure that senior executives provide visible support for change. And they don’t equip people throughout the organization with the knowledge, skills, and mind-sets required to drive enduring improvements. Finally, many overrely on technology to effect long-lasting, meaningful change, though technology won’t help if people don’t also change how they perform their jobs.

Adopting Lean practices could help companies overcome these hurdles. Lean, made famous by Japan’s Toyota Motor Company, emphasizes involving employees in driving transformational and ongoing incremental improvement. It’s a holistic approach, entailing modifications in a company’s operating systems, management systems, and mind-set and behaviors. While often associated with the automotive industry, Lean transcends that sector and can help companies in many others—including mining—enhance productivity by reducing waste and creating greater value for customers.

Winning with Lean

About 10 percent of the mining companies from BCG’s recent study have begun experimenting with the Lean approach. But to get the most from Lean, these and other miners will need to avoid several all-too-common pitfalls.

Sure, Toyota has had decades of experience with Lean, and its best practices—along with its spectacular successes—have been thoroughly documented. Yet it’s easy to oversimplify the Lean approach and misunderstand how Toyota and other successful adopters have used it. Companies that fail to anticipate and manage challenges that come with implementing Lean risk wasting time and money—or even destroying value.

Below, we outline several major “don’ts” associated with implementing a Lean program and explain how mining companies can avoid them.

Don’t take a piecemeal approach. As a process-innovation framework, Lean must be approached holistically rather than piecemeal. Companies embarking on a Lean journey need to drive change simultaneously on three fronts: operating systems (rules, guidelines, standards, methods, and beliefs governing system performance), management systems (such as how performance is measured and rewarded), and mind-sets and behaviors (organizational culture).

Take a piecemeal approach to Lean, and you can sabotage productivity in different parts of your operations. For instance, if you transform your load-and-haul process to achieve unprecedented efficiency without paying attention to the change’s impact on other activities, you could create longer haul-truck queues at your crushers.

The lesson? Examine your entire value stream, identify which areas have the greatest potential for improvement (including which contain the largest bottlenecks), and decide which to optimize and in what sequence. Value-stream mapping, along with other analytical and diagnostic tools, can help. So can piloting your Lean approach. To conduct a pilot, select a part of your operations where processes and bottlenecks are relatively self-contained and where leaders recognize the need for change and are open to trying something new.

And don’t neglect the people aspect of transforming productivity through Lean. We’ve found that many people in the mining industry, even at executive levels, remain unfamiliar with Lean thinking. Lean immersion programs can help you equip your leadership teams and workforce with the training and perspective they need to change how they approach their jobs.

Training can also create space for people to air their concerns about the change effort and to share their productivity-improvement ideas, which fosters a sense of ownership of and commitment to your Lean program. But to make learning “stick,” follow theory-based training with practical-application opportunities.

Don’t overrely on tools and tech. Resist the urge to view Lean as a toolbox, keeping in mind the adage “If all you have is a hammer, then every problem you encounter looks like a nail.” Yes, the Lean framework includes specialized tools developed over decades. And mining companies have access to a wealth of advanced technologies—including low-cost, network-connected sensors and actuators; increasingly powerful control systems for machines; high-speed network connectivity across mining operations; and inexpensive computer processing and data storage.

But to get the most from tools and technology, you should first define the business problem that needs solving. Only then can you identify tools and technologies that would best help you solve that problem.

Don’t go it alone. Lean implementations are complex, so find an experienced leadership and methodology guide to help. This individual will likely have been a senior leader in a successful and recognized Lean organization. He or she can also help you resist the urge to declare victory too early, such as after a success in your first target operation. Genuine victory comes only after multiple, sustained successes across your organization.

Augment your guide with high-potential transformation leaders in your organization. The best leaders will be people who are excited about doing whatever’s necessary to boost productivity and who know how to inspire others to embrace and help drive change.

Transforming a mine’s productivity will always be challenging. But by avoiding common pitfalls, mining companies can flip the odds of sustaining meaningful improvement—and lifting TSR.

This article was first published in Mining Journal on April 3, 2015.