With annual revenues of nearly $10 trillion, or about 6% of global GDP, the engineering and construction (E&C) industry is a cornerstone of the world’s economy. It serves almost all other industries, much of whose value creation involves buildings, infrastructure facilities, and other “constructed assets.”

Yet, unlike other industries, E&C has been slow to adopt new technologies and has never undergone a major transformation. Consider, for example, the opportunity offered by lean process methodologies—take-up has been limited, and many companies that have adopted them have failed to apply them wholeheartedly. In addition, construction firms now find themselves struggling to cope with ever-larger and more complex “

Substantial change is on the way, however, driven by digitalization: the development and deployment of digital technologies and processes. Construction will soon be characterized by connected systems of sensors, intelligent machines, mobile devices, and new software applications—all integrated on a central platform of building information modeling (BIM). As their adoption increases,

Other industries, such as the automotive industry, underwent radical process changes earlier and are now well into their digital transformation. In E&C, digitalization is just beginning. Given the sector’s vast size, however, even small improvements will translate into substantial benefits for companies and for society.

Within ten years, according to our estimates, full-scale digitalization in nonresidential construction will lead to annual global cost savings of $0.7 trillion to $1.2 trillion (13% to 21%) in the engineering and construction phases and $0.3 trillion to $0.5 trillion (10% to 17%) in the operations phase.

Digitalization will change the game fundamentally in E&C, not only enabling efficiency and quality gains along the value chain but also reshuffling the competitive league table of companies and countries.

The following sections of this report outline the main technological advances that will soon transform E&C, highlight the most important digital opportunities along the asset life cycle, assess the overall impact of the technology transformation through three case studies, and explore the implications for stakeholders.

The Manifestations of Digital Technology

“In the 32 years I’ve been in construction, this is the first time that technology is ahead of what we do. It has accelerated at a pace I’ve never seen…. There is technology that can operate machines unmanned. Figuring out how to make that technology work, in stride with our employees and partners, is paramount for us as a business.”

— Global head of operations, multinational construction company, 2015

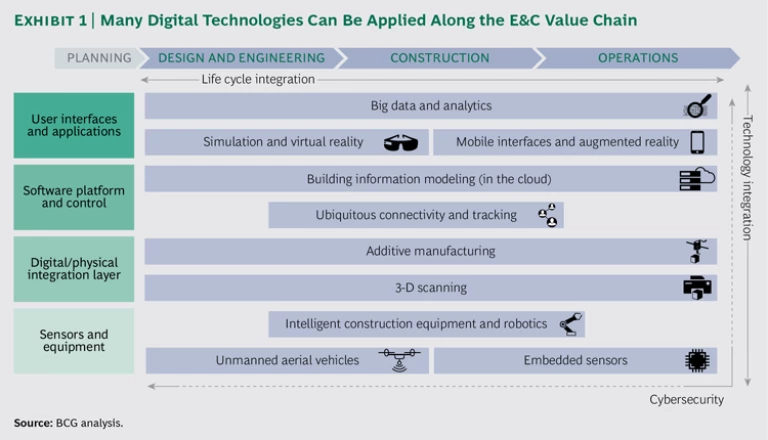

Many of the digital technologies pervading today’s industrial landscape are readily applicable to all three phases of the E&C value chain—design and engineering, construction, and operations. (See Exhibit 1.)

Some skeptical observers have questioned whether a fragmented industry comprising millions of small low-tech enterprises can actually undergo a technology transformation. But many of the traditional barriers have been eliminated: cloud solutions are now readily available, smartphones have proliferated—even in places such as rural India and Africa—and unprecedented advances have been made in ease of use.

The key feature of the technology transformation is the software platform and control layer, which consists in large part of BIM. As the successor to traditional computer-aided design (CAD), BIM now serves all stakeholders along the value chain, using virtual modeling and information to simulate any aspect of the asset’s life cycle. (For more about BIM, see the Appendix, “BIM—The Centerpiece of Digital Transformation in E&C.”)

The software and control layer resides within an architecture of supporting technologies. At the bottom are embedded sensors, now available at a small fraction of the cost of just a few years ago. They can conduct real-time status monitoring on any part of a building, during both construction and operations, and they constantly refresh and supplement the data base. But advanced digital solutions have moved far beyond that: we are now seeing the use of drones to survey and inspect construction sites. Even “out-of-sight” flights are becoming feasible, thanks to advances in obstacle detection and an easing of regulations. And “watching” is turning into “doing”: robotic machines are now able to turn data into physical action, autonomously and safely and anywhere. As a consequence, automated and unmanned operations are taking place at, for example, mining construction sites.

Further up the architecture, new additive manufacturing methods, such as 3-D printing, are becoming applicable even to large-scale building components and concrete structures. Companies can also use 3-D scanners to create digital models of complex buildings and thereby facilitate renovations, conduct quality assurance, and monitor deterioration of materials. And the possibilities of GPS and radio-frequency identification (RFID) are being exploited to track materials, equipment, and workers.

As part of BIM, mobile user interfaces and augmented reality are allowing real-time communication with remote construction workers and maintenance crews, and virtual reality and simulation are improving decisions, planning, and training.

A final aspect of the architecture is big data and analytics, which the construction industry is beginning to use to advantage. Analytical methods now make it possible to process the huge amount of heterogeneous data generated by construction projects and their environments, and to exploit that data to enhance building design, facilitate real-time decision making, increase the accuracy of predictions, and support systematic improvement.

In case some of these developments sound unduly futuristic, it is worth studying a few examples of these tools in action.

Digital Opportunities Along the E&C Value Chain

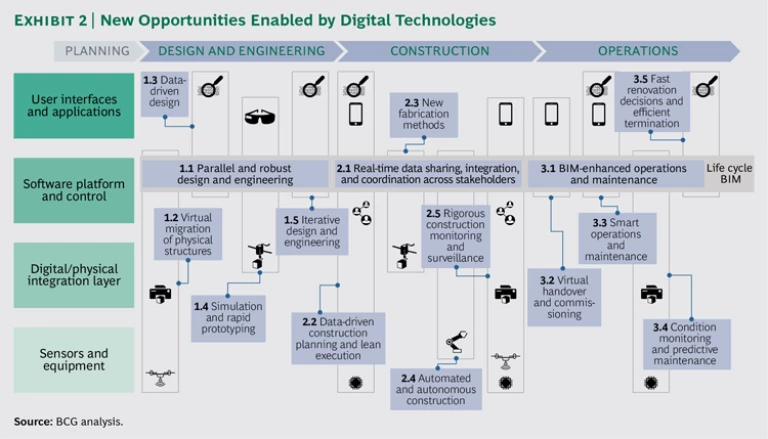

The application of digital technologies in specific use cases demonstrates the enormous opportunities along the value chain, from early conceptual design to the very end of an asset’s life cycle, in the demolition phase. (See Exhibit 2.) By applying the right technologies in the right way, companies can not only reduce the asset’s construction time and whole-life-cycle cost but also enhance the quality of processes and improve safety, working conditions, and sustainability.

The role of BIM is pivotal in this context, both for providing new use cases and for facilitating existing ones. Digital technologies are invaluable in all three phases along the value chain.

Design and Engineering

Although the most substantial new benefits will accrue in the construction and operations phases, digitalization will continue to increase efficiency through new forms of design and engineering and increased frontloading.

1.1 Parallel and Robust Design and Engineering. BIM enhances design and engineering processes and facilitates their parallelization by helping architects, engineers, and other project partners to merge their models, identify interdependencies and clashes, and rapidly evaluate design iterations. For instance, at Crossrail—a major new underground rail line across London, one of the world’s largest and most complex infrastructure projects—designers and engineers are using a set of linked BIM databases to integrate about 1.7 million CAD documents into a single information model. This model promotes consistency and coordination despite the project’s vast scope and the huge number of interlinked interfaces within the city’s convoluted urban environment.

1.2 Virtual Migration of Physical Structures. Aerial mapping technology and 3-D laser scanning can each be used to convert existing buildings and infrastructure into virtual 3-D models. That capability greatly benefits renovation and retrofitting projects by increasing accuracy and saving time relative to manual measurements.

1.3 Data-Driven Design. Big-data analytics—for instance, of people’s behavior or the infrastructure environment—helps to optimize design decisions and enhances a facility’s operational efficiency. The engineering giant Arup, for example, combines various data-collection methods—including mobile surveys, security camera footage, and traffic flow reports—to inform and refine its design decision making in residential and infrastructure projects.

1.4 Simulation and Rapid Prototyping. New modeling techniques—simulation enhanced through holographic technology, for instance, and rapid prototyping with 3-D-printed models—speed up design iterations and improve visualization. These techniques are being applied, for example, in Gaudi’s famous Sagrada Família church in Barcelona, where 3-D-printed plaster models of the building’s many complex components are greatly facilitating the resumed construction process.

1.5 Iterative Design and Engineering. Software tools integrated with BIM confer a number of benefits—such as automatically generating and evaluating design alternatives, supporting value engineering, and enhancing design-to-cost, design-to-fabrication, and sustainability analyses. A case in point: by conducting a BIM-based energy analysis early in the design stage, the Oregon-based firms Sera Architects and Hoffman Construction, working jointly on a hotel renovation, achieved energy savings of 30% for ongoing operations and a 29% return on sustainability expenditures.

Construction

Digital design greatly enhances efficiency in the construction phase by detecting and averting potential interference and by optimizing constructability. This phase also draws on other aspects of BIM and complementary technologies.

2.1 Real-Time Data Sharing, Integration, and Coordination Across Stakeholders. One major challenge during the construction phase is to provide all parties—from suppliers to subcontractors to the on-site crew—with the right information at the right time in the right place. BIM in the cloud enables all stakeholders to share data in real time and to integrate and coordinate their activities. In that way, collaboration becomes less error-prone and more efficient. An interesting example is the stadium of the Washington Nationals baseball team in Washington, DC. While the structural steel component was being erected, BIM technology kept all supply-chain participants so well informed that requests for design clarification numbered fewer than 100, compared with the estimated 10,000 for a comparable non-BIM project.

2.2 Data-Driven Construction Planning and Lean Execution. For optimal resource allocation and scheduling at the construction site, companies can hone their project-management tools with the help of big data (derived from past projects, for instance) and RFID tracking (of material, equipment, and labor). In that way, companies reduce non-value-adding activities (such as waiting, moving personnel, and transporting material and equipment) and maintain a lean approach. Take the engineering, procurement, and construction company Fluor, for example: to improve decision making, the company draws on a system dynamics model—informed by prior project experience—to simulate the impact of potential changes on a diverse range of construction projects. Course corrections are duly made, and impressive savings realized—an estimated $700 million on a sample of 100 projects.

2.3 New Fabrication Methods. Virtual building models contain detailed information that can facilitate new approaches to fabrication, including modularization, prefabrication, and 3-D printing of individual components. Many benefits result, such as better sequencing of construction processes, a reduction in weather-related delays, safer working environments, and improved material yields.Simulations of the integration of complex, prefabricated assemblies can be used for training and can help to identify optimal ways of handling equipment.

2.4 Automated and Autonomous Construction. Robots and intelligent machines enhance productivity, precision, and safety at the construction site. Remote-control systems and 3-D-model guidance enable advanced levels of automation (comparable to computerized numerical control in manufacturing)—for excavators, mobile cranes, and dump trucks, for instance. Eventually, the most complex and hazardous tasks will be assigned entirely to autonomous or semiautonomous construction equipment. A case in point: the Japanese equipment manufacturer Komatsu has developed fully autonomous bulldozers, which are guided by drones that map the area in real time and provide data on the amount of dirt and rocks to be moved.

2.5 Rigorous Construction Monitoring and Surveillance. Digital measuring and monitoring devices allow companies to track construction processes and activities more rigorously. To minimize corrective work, 3-D laser scanning is used continually to compare structures to the model. And drones and remote cameras survey construction sites, while telematics systems transmit data on multiple machine parameters, such as fuel consumption, for optimized fleet management. According to Benoît Potier, the chairman and CEO of Air Liquide—a world leader in industrial gases—the company’s engineering unit now performs full 3-D scans of its plants.

Operations

The operations phase benefits from digitalization mainly by exploiting the advanced performance analyses that had been conducted in the design phase and by utilizing the building information received by the operator at handover after the construction phase. The second aspect involves BIM in several ways.

3.1 BIM-Enhanced Operations and Maintenance. BIM facilitates the operations and maintenance (O&M) of a building by providing a virtual model of it. The model functions as a repository of information generated during the earlier phases and supplemented or refined during the operations phase. Consider the approach taken by the Japanese building-service provider NTT Facilities to the inspection, maintenance, and repair of its R&D premises: by integrating the BIM model into the building’s facility- and asset-management system, and making intelligent use of this combined resource, the company reduced the O&M cost by an estimated 20%.

3.2 Virtual Handover and Commissioning. Digital devices and techniques can streamline commissioning processes impressively. For instance, companies can gather test data or inspection data on-site and—by means of mobile devices equipped with bar code scanners—transfer that data directly to the counterpart object in the 3-D model. Moreover, BIM enables the efficient transfer of data without loss of information to a building’s owner or operator. The data can be used to simulate operation of the facility prior to launch and automatically populate asset registers.

3.3 Smart O&M. By merging and analyzing data from multiple sources, including BIM, companies can increase the efficiency of their O&M activities and open up new possibilities. A smart system in this regard is being developed by BIM service provider BDS VirCon in collaboration with IBM: maintenance crews at plant sites can access augmented-reality technology to overlay the actual view with a BIM model showing hidden features, such as mechanical and electrical components. At the same time, they can access supplementary information, such as repair manuals or the stock level of spare parts.

3.4 Condition Monitoring and Predictive Maintenance. With real-time access to accurate data—through sensors, cameras, or 3-D laser scanners—companies can monitor buildings continuously and conduct predictive maintenance. In that way, they reduce the number of manual inspections and unexpected failures, and the amount of preventive maintenance, and they thereby cut costs considerably. At Rutgers University, researchers have developed a fully automated device that uses imaging, ultrasonic, echo, radar, and other technologies to detect deterioration in bridges, thus lowering costs and improving maintenance, repair, and rehabilitation decisions.

3.5 Fast Renovation Decisions and Efficient Termination. A well-maintained BIM model can help designers and engineers to evaluate the likely impact of major repairs and retrofitting or the implications of closing down a facility. By accessing detailed information on previously used materials, for instance, they can identify the optimal recovery options for demolition waste.

To what extent are E&C companies already using digital technologies? As shown above, there are compelling success stories, but many have been driven by a group of pioneering design and engineering consultancies, as well as large engineering, procurement, and construction firms. All companies in the E&C value chain must learn to leverage the comprehensive portfolios of digital technologies—or be left behind.

The Impact of Digital in E&C

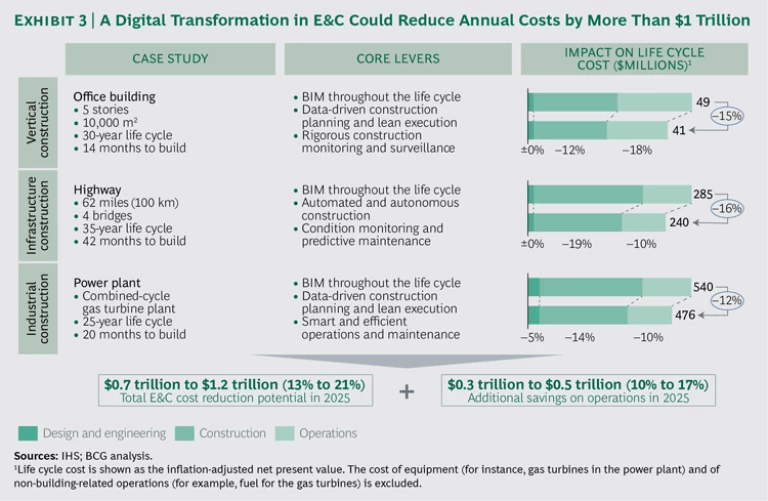

Our expectation is that, over the next decade, more and more companies will embrace the manifold opportunities offered by digitalization, and productivity across the E&C value chain will soar. To gauge the potential worldwide impact of this digital transformation, BCG analyzed the outlook for three construction subsectors: vertical construction, infrastructure construction, and industrial construction.

We selected three prototypical case studies—an office building, a long-distance highway, and a power plant—to assess the expected efficiency gains in more detail. (See Exhibit 3.) We evaluated the impact of a broad set of technologies and experiences from similar real-life projects and validated the estimated cost reductions with industry experts. We then used additional parameter adjustments and construction revenue data provided by IHS to extrapolate to E&C as a whole.

The overall findings were these: by 2025, the total global cost-saving potential in nonresidential sectors will be $0.7 trillion to $1.2 trillion per year in design, engineering, and construction and $0.3 trillion to $0.5 trillion per year in operations. These productivity gains will vary, as described in Exhibit 3, across subsectors and life cycle stages.

Vertical Construction

In vertical construction, such as commercial and institutional buildings, digital technologies could reduce the costs of design, engineering, and construction by 10% to 15%. Complex buildings such as hospitals should do even better, achieving savings of 15% to 25%. Cost savings in the operations phase could range from 14% to 23%.

For the office building in our case study, three main levers—BIM applied throughout the life cycle, data-driven construction planning and lean execution, and rigorous construction monitoring—reduce total life-cycle costs and construction time.

- Design and Engineering. Efficiency increases in this phase thanks to improved coordination and BIM modeling tools. However, the costs incurred during this phase do not decrease, because they now include supplementary analyses, such as a detailed energy simulation.

- Construction. In this phase, productivity is enhanced in various ways. Pull planning and real-time on-site tracking ensure optimal allocation of resources. Rework is greatly reduced, because 3-D laser scanning monitors progress. In addition, BIM makes it possible to prefabricate large assemblies. Thanks to the elimination of non-value-adding activities, construction can be completed nearly 30% faster—in 10 months rather than the traditional 14, in our example. Cost savings are less pronounced—12%—because the building materials account for a very high share (70%) of overall costs.

- Operations. Cost reductions in this phase are an impressive 18%. Major savings are realized through improved energy efficiency (enabled by the optimized office design) as well as by BIM-facilitated maintenance and renovation.

Infrastructure Construction

Many infrastructure projects—such as transportation and energy distribution facilities—will realize a 15% to 25% reduction in E&C costs. For waste- and water-treatment facilities, savings will be somewhat lower, 10% to 20%. For all infrastructure projects, the potential savings in the operations phase will be 8% to 13%.

Our case study, a long-distance highway project, shows how performance is enhanced by digitalization, specifically through the application of BIM throughout the life cycle, automated and autonomous construction equipment, and condition monitoring.

- Design and Engineering. The efficiency gains achieved by BIM technology in this phase are largely offset by the associated costs—of enhanced clash detection and constructability and of optimizing design for traffic, signage, noise, lighting, and drainage.

- Construction. In the highly repetitive workflows of the construction phase, there is huge potential in leveraging state-of-the-art automated and connected machinery, such as excavators, bulldozers, and compactors. Such machines—linked to the 3-D model, a fleet-management system, and optimized routing software—perform tasks faster, more accurately, and with minimal supervision. Frontloaded design streamlines the construction process by reducing the need for corrrective changes and rework on-site. Overall, construction time is reduced by 23%—from 42 months to 32, in our example—while construction costs (35% of which are attributable to materials) go down by 19%.

- Operations. The potential cost reduction here is 10%. This is mainly due to the optimized design of the highway and to the wireless condition monitoring of roads, bridges, and tunnels, which reduces the need for manual inspections and enables predictive maintenance.

Industrial Construction

In industrial projects, the cost-saving potential in design, engineering, and construction is assessed at 10% to 20% for power and chemical plants and 10% to 15% for oil and gas facilities and discrete manufacturing plants. Savings in the operations phase are estimated at 8% to 13%.

Our case study, a combined-cycle power plant, shows how strong the benefits of digitalization are in a complex setting, even one that is already technologically advanced. The main digital levers here, in addition to BIM throughout the life cycle, are data-driven construction planning, lean execution, and smart O&M.

- Design and Engineering. BIM helps to improve design efficiency—in particular, enabling the reuse of objects from comprehensive libraries. As a result, despite the new costs of increased frontloading and of enhanced clash detection and constructability, costs decrease by about 5%.

- Construction. The main driver of efficiency gains in this phase is lean project management, which, in turn, relies on virtual construction simulation and real-time tracking of progress on-site and along the supply chain. There is only modest potential for using a more robust design to reduce corrective changes and rework—certainly far less potential than in vertical and infrastructure projects. Overall, the savings are 15% in construction time and 14% in construction costs (only 12% of which are attributable to materials).

- Operations. In a complex plant environment, detailed information on each part of the facility, including equipment, is required at frequent intervals. Our combined-cycle power plant uses an integrated BIM enterprise-resource-planning and building-automation system to drive efficiency in maintenance, plant upgrades, and asset management. The result is a 10% decrease in operations costs.

The Way Forward: Implications for Stakeholders

National regulators, industries, and individual companies are approaching digitalization at different speeds and in different ways. That variability widens the gap between leaders and laggards—whether participants in the E&C value chain, technology suppliers, or countries.

Inevitably, there have been initial barriers to adoption, such as high investment needs and a shortage of industry-wide proof of value. But these barriers are falling. The digital ecosystem is flourishing, driven by government incentives; large, pioneering firms are ramping up their digital agendas; and many new companies with digitally enabled business models are entering the market.

To succeed in this challenging environment and reap the most benefits from digitalization, all stakeholders should take decisive action.

E&C companies must shape the digital transformation. The immediate priority for E&C executives should be to

E&C executives should take the following steps:

- Build teams that have the new digital competencies. Become a magnet for “digital natives.” Set up a central innovation or BIM department to institutionalize digital endeavors and expand the digital knowledge base more quickly. If your company is a large one, appoint a chief technology officer.

- Establish the technological foundation. Identify and prioritize the most relevant digital technologies according to their maturity level and business and market needs. Invest in the requisite software and hardware tools and IT infrastructure. Make sure to gain access to or ownership of relevant data generated along the building life cycle.

- Spread digital skills across the company. Assess the required changes in your workforce at large; specifically, take digitalization into account in your strategic workforce planning. Changes can go both ways: there will be a need to upgrade and provide training for the relevant digital skills, but some complex tasks can now be performed by lower-skilled workers, thanks to

decentralized information and augmented reality4 4 For an analysis of the impact of digitalization on the workforce in an industrial context, see Man and Machine in Industry 4.0: How Will Technology Transform the Industrial Workforce Through 2025? BCG Focus, September 2015. . Establish a company culture that is conducive to innovation and improved digital skills. Make sure that all dispersed divisions and teams are part of the transformation. - Complement digital capabilities through third parties. Collaborate with suppliers, competitors, and project owners to accelerate learning and compensate for any lack of internal resources. A liaison with a start-up, such as that between the construction giant Bechtel and the drone pioneer Skycatch, can help a large incumbent company to benefit from digital advances quickly.

In addition, E&C companies should

- BIM and other new technologies will increase integration across all phases of the E&C value chain, thereby demanding more-integrated forms of project delivery and alliance models. That will fuel the need for broader life-cycle competencies, which can be realized, for example, by diversifying horizontally through mergers and acquisitions (M&A).

- In regard to design and engineering, the emergence of comprehensive object libraries will commoditize simple tasks, while increased parallelization of work streams will facilitate distributed engineering and offshoring.

- For construction contractors, increased transparency through BIM will reduce the relevance of claims for change requests as a revenue stream.

Technology suppliers must respond to new demands. The digital transformation of E&C creates valuable opportunities for technology suppliers. BIM alone is a $2.5 billion software market, growing by more than 15% per year, and it is boosting ancillary markets many times its size in sensors, equipment, and services.

As the suppliers of BIM and supplementary technologies fight to establish standards and capture market share, they should take several steps:

- Continually strengthen core products and strive for standards. Strengthen product offerings for the traditional target group of designers and engineers by adding functionalities and modeling dimensions, improving usability, and simplifying the reuse of data from past projects. Agree with other suppliers on standards in order to improve the interoperability of BIM systems and to integrate all disciplines.

- Extend your efforts beyond the design phase. Put equal energy into serving the construction market as well. Adapt to the needs of construction companies by better integrating hardware and software and by improving on-site compatibility (for example, providing data filters and one-click print functions for work crews in the field). Launch initiatives—such as value proofs, joint pilots, and digital-skills training courses for clients—to speed up the adoption of new digital technologies. Offer cloud-based solutions and, for smaller construction companies, make software affordable by offering a version with restricted functionality.

- Address critical interfaces and explore new frontiers. Address new links in the value chain and new market segments. Offer facility operators a clearer value proposition for their use of the BIM model after handover—especially the operators of complex plants. Ensure smooth interfaces between BIM and adjacent facility-management, asset-management, and building-automation systems. Provide holistic solutions for the entire design-build-operate life cycle.

Governments must make conditions more conducive. Digital technologies will realize their full potential only if they become the industry norm. It is crucial to create a fertile environment for the digitalization of the E&C sector. That is the task of government, as regulator and incubator, and often as a key project owner. Witness the UK, where BIM has been placed on a national strategic agenda and mandated in flagship projects such as Crossrail. As a result, the country has one of the world’s highest BIM adoption rates. In response, even the traditional laggards, such as Germany, have launched similar ambitious initiatives.

As regulator and incubator, government can take the following steps:

- Adjust building codes and define new standards for the interfaces between, for instance, BIM and other technologies.

- Promote R&D through measures such as tax incentives, venture capital, and joint industry-academia funds and technology centers.

- Help the E&C sector to develop workers’ skills by offering joint training programs, for instance. Adjust curricula in universities, technical colleges, and apprenticeships.

As a key project owner, government can take the following steps:

- Review the asset and construction process specifications of all projects in light of newly available technology.

- Create incentives for digitalization and innovation by engaging in performance-based procurement and introducing a more flexible bidding system.

- Make sure that requests for proposals require respondents to discuss new digital technologies.

Other stakeholders must make appropriate adjustments. Private owners of projects, in order to capitalize on the improved efficiency in the E&C value chain, need to demand the digital technologies that best suit each project. Suppliers of construction equipment, in order to take advantage of the major digital trends, should position their offerings as complementary to BIM technology. The unstoppable migration of smart building technology to design, engineering, and construction also affects participants in the wider ecosystem, such as providers of building automation systems: they must redefine their roles or else end up as mere executors. Suppliers of building materials must adapt their strategies to increasingly transparent and competitive markets.

The E&C sector has finally set out on the digital pathway, and a profound transformation—long overdue—now seems inevitable. The sector as a whole is bound to benefit; so, too, is society at large as well as the international economy.

Individual companies that continue to ignore the digital wave will struggle to survive. For the adopters, speed matters: there is only a narrow window of time during which digital savvy provides a significant competitive advantage over the average industry participant. If companies want to contribute to redefining the competitive landscape, they need to seize the opportunity soon.

Appendix: BIM—The Centerpiece of Digital Transformation in E&C

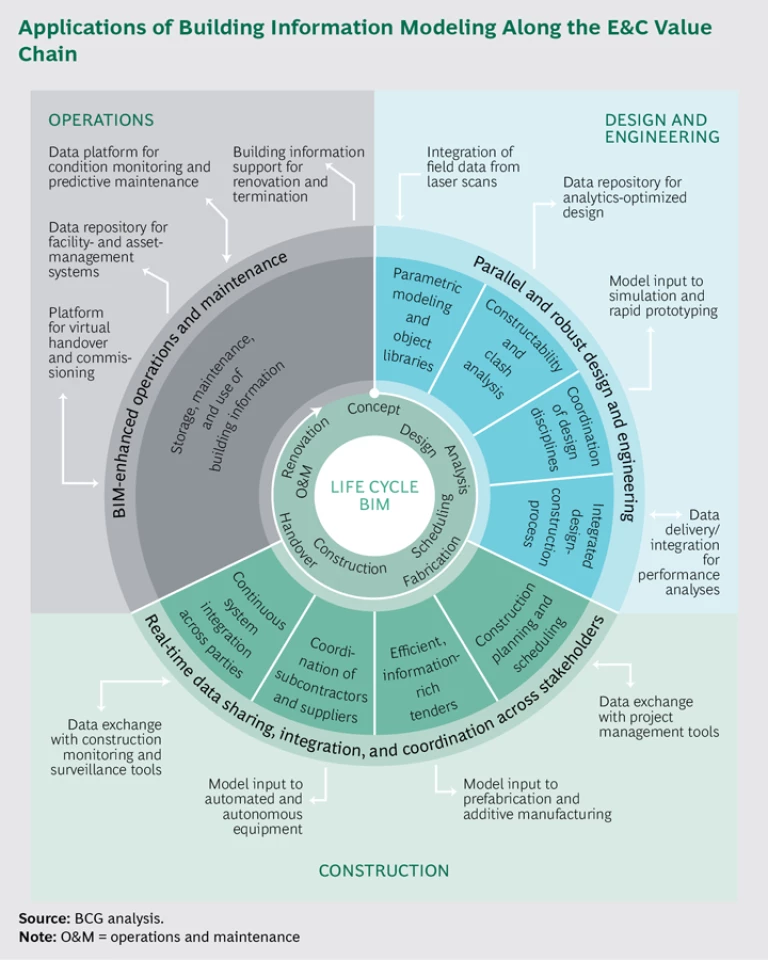

Building information modeling (BIM) is taking center stage in the digital transformation of the E&C industry. It serves as the focal software platform for integrated design, modeling, planning, and collaboration; it provides all stakeholders with numerous benefits throughout an asset’s life cycle, including much smoother integration across phases; and it enables or boosts many other digital technologies. Its effects are felt during all three of the main life-cycle phases. (See the exhibit.)

The design and engineering phase is traditionally the most receptive to BIM, which serves as the technological and process successor to CAD and 2-D and 3-D drawings. BIM’s parametric modeling approach enriches each object in a digital 3-D model by attaching a variety of information to it and guarantees the consistency of all drawings, reports, and data interfaces. Design and engineering elements can easily be imported from digital object libraries and checked for compliance with specifications and regulatory requirements. Automated geometric and rule-based analyses help to identify potential design clashes and constructability issues, thereby averting costly corrective changes and rework on-site. Integrated workflows among design disciplines further mitigate design errors and shorten the design stage. Finally, by making early construction-level planning (including quantity takeoffs) possible, BIM supports new, more collaborative forms of project delivery, such as design-build or integrated project delivery.

During the construction phase, BIM enables companies to simulate and sequence activities in time and space, thus creating various scenarios of procurement, resources, and spatial and other constraints. As such, it provides the foundation for a more “lean construction.” BIM also helps companies to manage subcontractors and suppliers in several ways. First, tendering processes become more efficient and transparent, thanks to the wealth of accurate information derived from the building model and given to potential bidders. Second, subcontractors and suppliers can be informed about scope and design changes in real time, thereby reducing the number of requests for information. Third, BIM ensures that all parties’ systems are compliant with designs.

During the operations phase, BIM (as a central part of an integrated facility- and asset-management system or as a supplementary data pool for the latter) has numerous potential applications, though these are not yet in wide use. BIM allows companies to store, maintain, and access building information, including spatial, technical, and warranty data, and thereby to conduct their commissioning and operations and maintenance (O&M) activities more efficiently. Moreover, a well-updated BIM model can greatly simplify the planning of major repairs, retrofits, and expansions.

In addition to these core benefits during the three phases, BIM has the virtue of interacting well with other digital technologies—facilitating their adoption or enhanced application and benefiting from them in return. For example, BIM enables companies to store and process data from 3-D laser scans in renovation projects;

delivers the input data required for prefabrication and automated field equipment; and readily links to measurement sensors and mobile devices, during both construction and operations.

BIM is able to integrate and apply an abundance of external data. It also enriches several software applications and data systems central to digitalization in E&C, such as analytics, simulation, and value-engineering software during the design and engineering phase, project management tools in the construction phase, and facility- and asset-management systems in the operations phase.

Geographic information systems (GIS), which are used to map and analyze structures in their geospatial context, are an important large-scale technology that complements BIM—although the integrating interfaces have not yet been fully defined. GIS plays a key role in the planning of pipes, large projects, and even entire urban developments. During design, engineering, and construction, GIS plays mainly a supporting role; in operations, it is used for managing large building complexes.

Acknowledgments

The authors are grateful to their BCG colleagues Romain de Laubier, Roland Haslehner, Armin Lohr, and Massimo Russo for contributing their insights to this report. They also thank Katherine Andrews, Gary Callahan, Angela DiBattista, Kim Friedman, Abby Garland, Amy Halliday, and Sara Strassenreiter for contributions to editing, design, and production.