We’ve all heard about how machine learning is revolutionizing different industries. This technology presents real opportunities. But too often, media headlines and sales presentations make empty claims about its promise rather than zeroing in on the business problems it can solve. Sorting through the hype can be daunting for any mining manager.

Mining managers routinely must make critical operations decisions, while meeting day-to-day obligations such as safety and production targets. Such decisions typically involve complex tradeoffs (such as between operating cost and yield in processing plants). Yet many managers make suboptimal decisions, relying on simple spreadsheets or rules of thumb. Taking advantage of machine learning can help them avoid this pitfall. But first, they must familiarize themselves with the technology.

Machine Learning: A Quick Primer

Machine learning , a subfield of artificial intelligence, comprises algorithms that aim to understand relationships in complex data sets and that use that understanding to make predictions. These predictions can be simple (such as what temperature an equipment component will reach under certain conditions) or complex (for instance, whether and when a crusher will fail).

The algorithms “learn” by discovering relationships in the data, without a person having to program specific rules, relationships, or equations. Through such learning, an algorithm can detect complex patterns emerging from thousands of variables—even in complex operating environments such as mines.

In fact, machine learning today routinely tackles problems that were impossible to solve as recently as five years ago, owing to the wealth of data available and the rise of cheap sensors and smart devices. New analytical tools, algorithms, and data transmission technologies let managers analyze data they previously could not. Cheap and easy storage, along with massive increases in computing power (including scalable cloud computing), have made data analysis more affordable than ever. Forward-thinking miners are taking advantage of these developments to explore the benefits of machine learning for their operations.

Machine Learning in Action in Mining

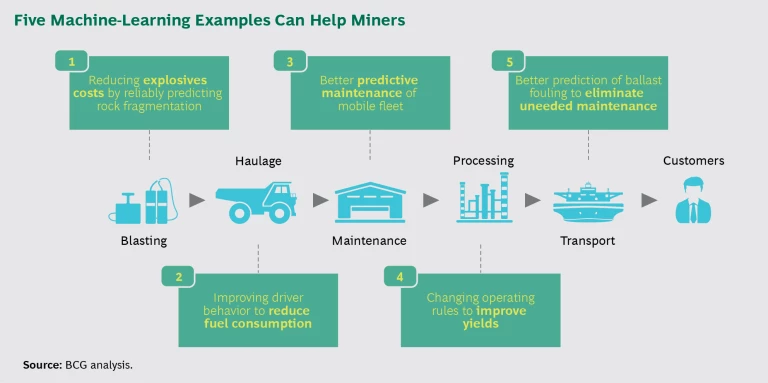

Machine learning can help miners uncover valuable insights, drawing on the real-time, high-volume, and unstructured data typically seen in mining. Here are five proven examples, illustrated in the exhibit below, that miners could consider to get started:

Blasting. How do you measure the impact of a high-energy explosive at a mine site when every blast varies, and you can’t repeat a blast? One mining company called in a team of data scientists to answer this question. The scientists applied machine-learning techniques to understand the relationship between drill hole patterns, blast design, explosive type, geology, and observed rock fragmentation from roughly 80 blast events over six months. Once their analytics model had learned the interrelationships in the data, it could make reliable predictions about the fragmentation that would have happened had a different explosive type been used. The mining company could then use this information to select the right explosives to minimize cost for the desired rock fragmentation outcome.

Haulage. When it comes to haulage, driver behavior powerfully influences fuel consumption in open-pit mines. With this in mind, a Congolese copper mine—with multiple pits and stockpiles, a complex road network, and a largely unskilled workforce—set out to quantify the impact of poor operator behavior on fuel consumption. It brought in data scientists, who used low-cost spatial trackers and drones to capture real-time information about trucks’ location, time, speed, and vibration. The scientists then used specialized software and a statistical toolbox that leveraged neural-network techniques to analyze truck dispatching and track vehicle movement. The result was direct feedback that showed operators how they were driving their trucks. Armed with this knowledge, they were able to limit peak speed, reduce short stops and restarts, and avoid abrupt braking and strong acceleration. In just eight weeks, fuel consumption dropped by 7%.

Maintenance. Mining equipment often exhibits a signature “fingerprint” (pressure or temperature spikes, electrical signals, oil leaks, noise, and vibration) before it breaks down. With low-cost sensors, more data than ever is available on equipment status, but this can lead to information overload for engineers and managers.

Algorithms can learn to identify the unique (and often complex) signatures of a failure by modeling the relationship between observed failures and data on factors influencing equipment status, such as operator behavior, historical maintenance, and weather. In some cases, the algorithms can detect impending failure days in advance. Such analysis can help miners efficiently schedule maintenance. The result? Increased equipment uptime, and a higher proportion of (lower-cost and safer) planned maintenance.

Processing. At a midsize copper smelter struggling with thin margins, engineers had tried for years to optimize yield, using their knowledge of chemistry and physics. But the complex data relationships and multiple, ever-changing variables stymied them. The company brought in data scientists to build an artificial neural network that analyzed years’ worth of data. The model showed that declining yields stemmed from the chemical recipe—not temperature as suspected. The smelter implemented a new set of operating rules that required no capital expenditure and achieved a 2% yield improvement.

Transport. Ballast fouling is a major problem for rail networks used in mining. Rail ballast—the track bed on which sleepers, or railroad, ties are laid—becomes dirty and dusty over time, leading to dangerous track deformations. Predicting when and how this will happen isn’t easy. Typically, rail operators collect extensive data but have difficulty anticipating which ballast areas will need cleaning when and what impact cleaning will have. Consequently, they spend as much as 20% of their annual maintenance and sustaining capital budgets on cleaning ballast.

One rail operator asked data scientists to conduct a five-week machine-learning proof of concept. They integrated data sets from ground-penetrating radar, maintenance, and weather; built a model to predict ballast fouling; and designed a customized optimization tool to help managers identify the best sections of track to remediate. Managers discovered that they could reduce ballast-cleaning costs by up to 13% by eliminating unnecessary maintenance.

Getting Started

While machine learning can help miners transform their operations, leveraging it takes some work. It takes time to decide which data to use, clean the data, and try various analytics models. Plus, there’s no one “right” machine-learning algorithm for all business problems. Each company must select and tailor algorithms that best reflect its own challenges and circumstances.

That being said, miners can take a few steps to begin exploiting machine learning—even if they don’t yet have sophisticated IT systems and tech-savvy experts at hand. Most important, they can address business decisions currently facing them. These decisions are difficult to make, owing to their complexity. They are being made using gut instinct or unsophisticated analytics tools (such as spreadsheets), and the stakes are high, because the difference between a good decision and the best decision has a material impact on value.

For such decisions, machine learning can be a powerful tool. “Sprints” can help miners generate tangible value within weeks. Such pilot projects use machine learning to address a particular problem that meets these criteria. They’re implemented in stages by teams comprising data scientists and in-house decision makers.

Successful sprints can inspire confidence and build momentum for additional testing and learning and a broader digital-mine program. But to get the most from sprints, miners should adopt a value-focused approach. They should identify the most promising machine-learning projects using input from diverse parts of the organization and bring in the right data science capabilities to support the projects.

Machine learning is helping miners sharpen their competitive edge. But today’s applications are just a starting point. The future will bring even greater opportunities for miners who lay the groundwork now to take advantage of this powerful technology.

This article was first published in

Mining Journal

on June 23, 2017.