Digital technologies that were either unimaginable or too expensive ten years ago are doubling utilities’ workforce productivity today. Forward-thinking companies fly drones over power lines rather than dispatching field inspectors every time. Remote sensors, smart meters, and individuals’ portable devices stream data that predicts when the field force should carry out essential maintenance. The most advanced utility companies employ artificial intelligence and augmented reality to guide field workers remotely so they can safely and quickly tackle outages.

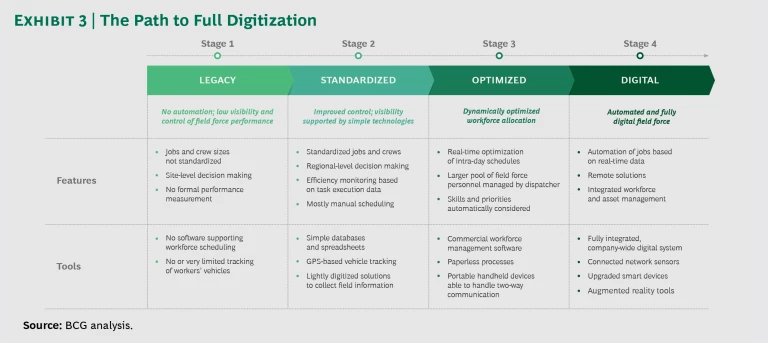

In our work with leading utilities, we identified four stages on the path to a digitally connected workforce. While full digitization is the ultimate goal, even organizations that move just a step or two along this path—for example, by standardizing and optimizing the legacy systems used to manage their workforces—can save significant costs and greatly improve efficiency and supply reliability.

Before we examine the specific stages, let’s look at the various conditions compelling utility companies to go digital today.

The Case for Modernizing Workforce Management Systems

The pressure is on for utility companies to improve performance. Regulators, investors, customers, and competitors demand shorter response times to outages and network faults, at minimal cost. In the US and Europe, changing demographics mean companies face the additional burden of finding skilled staff to replace experienced field workers as they retire.

Utilities can meet those challenges by improving how they manage their workforce. Field force workers, essential for resolving network faults, comprise more than half of most utility workforces. They account for about 40% of companies’ wage bill on average and represent 60% to 80% of capital expenditure (for field equipment maintenance and replacement).

Fortunately, digital workforce management solutions are far more affordable than they were even a few years ago. Field workers today can use apps on smartphones and tablets to access data stored in the cloud—a huge change from what companies routinely invested in tailor-made handheld devices and traditional packaged software.

Yet for all digital’s advantages, utility companies have been slower to adopt digital workforce management systems than companies in sectors such as retail and freight. We can blame the delay on legacy procedures, limited regulatory pressure to improve, labor union constraints, and security of supply considerations. But it isn’t too late for utilities to catch up and innovate with solutions that best address the industry’s unique challenges.

It isn’t too late for utilities to begin innovating with digital solutions.

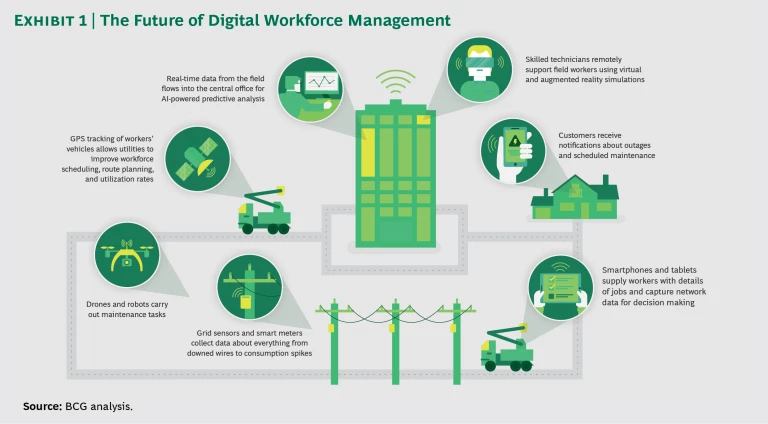

No company has yet achieved full digitization, but some leading companies are moving toward it by automating and integrating their workforce and asset management systems. The result? Improved capabilities in artificial intelligence, real-time data, and remote solutions. (See Exhibit 1.)

Most utilities, however, are still at the beginning stages of standardizing and optimizing processes. But even at those levels, companies can significantly improve workforce performance by standardizing procedures and tasks across regions and teams. Rather than relying on localized information, companies can manage workers using a central database. Likewise, technology optimizes task allocation by selecting the best workers for the job and choosing the quickest travel route.

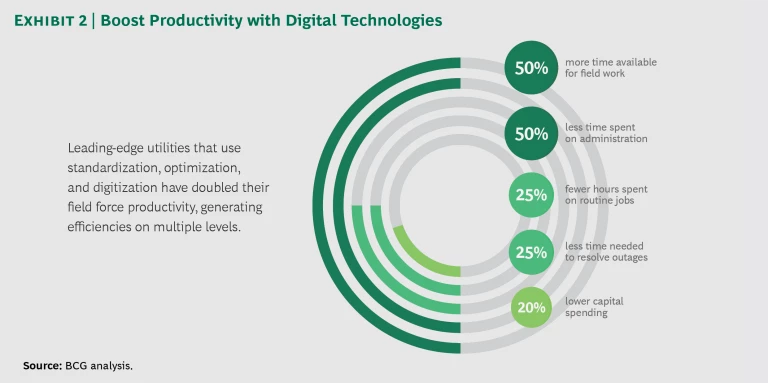

By standardizing and optimizing their workforce management procedures, companies can increase workers’ availability in the field by 50% and reduce by 25% the time needed for routine jobs. (See Exhibit 2.) The increased quality of job execution means that 30% fewer repeat trips are necessary. All of this means that field forces can do the same amount of work with less staff. And because quality assurance and work documentation is streamlined, administrative time is halved.

As companies move toward more advanced solutions, big data analytics allows information collected through field workers’ digital devices to build a real-time picture of equipment health. Such data enables fully digitized utilities to schedule predictive rather than routine maintenance, cutting their construction budgets by 20%. Let’s now look at the stages that lead to full digitization.

The Four Stages of Digital Workforce Management

Once a company identifies where it lies on the path to full digitization, it can begin to reap the benefits of each stage and progress to the next level. (See Exhibit 3.)

Stage 1: Legacy Solutions

Only a handful of companies still rely on legacy workforce management systems—the norm 20 to 30 years ago, before the rise of automation and modern mobile telecommunications. Legacy systems comprise mainly manual, paper-based processes in which decision making occurs onsite rather than remotely in the center of operations.

Stage 2: Standardized Operations

By standardizing and centralizing their workforce management procedures, companies can gain significant benefits with relatively little investment. Simple tracking tools such as vehicle GPS systems and crew smartphones, as well as spreadsheet-based IT solutions, allow managers to allocate tasks across a larger, single pool of workers; cut time spent on travel and task preparation; and compare performance across different teams.

For most utilities, a few common tasks, such as changing electricity poles, consume the majority of time in the field, and each local team uses its own approach. But by identifying procedures that most efficiently complete particular jobs—and then standardizing them in a visible way, such as by creating a set of guidelines for these tasks, companies can reduce how much time these common jobs take by 25%, on average.

Likewise, when utilities spend less time coordinating and preparing for jobs, the number of hours available for a worker to perform jobs can increase by an extra one to two hours per day and cut overtime by one-third. Companies can reduce travel time by up to 20% by scheduling jobs in close proximity so that the same team performs them.

By standardizing operations, utilities can reduce travel time by up to 20%.

All of these shifts in administration save substantial time. In fact, many utilities reduce the time ratio for planning (drafting detailed work plans and ensuring equipment availability) to field force hours from 1 planning hour for every 4 field hours to a ratio of 1 to 10. What’s more, managers can use the performance data collected from spreadsheet-based scheduling to assess field workers’ effectiveness and promote best practices.

The difference among regional teams before and after standardization is great indeed: the worst regions can easily spend twice the time on the same job as the best, especially with common tasks. By identifying an appropriate amount of time, crew size, skills, and equipment for a particular job—and making these standard requirements through scheduling—companies reinforce efficient work practices.

Stage 3: Optimized Scheduling

When companies adopt a push-based dynamic scheduling process, tasks are matched with the available field force. That means the best team can be tasked with fixing a problem unfolding in the field on the basis of the team’s location and skillset, while another crew picks up the team’s original job.

Assigning crews according to their proximity to the problem site reduces unnecessary travel, shortens response times, and increases productivity. With such dynamic scheduling, jobs can be easily reassigned if existing plans change, and workers can take on small, fill-in jobs when they finish tasks early—all of which maximizes effectiveness throughout the work day.

Because dynamic systems use more digital information, utilities can cut ratios from 1 scheduling staff member per 15 field workers to 1 staff member per 80 in the field. And because workers receive job information through their portable devices, they reduce unproductive time previously spent reporting to a central depot every morning.

Optimizing scheduling requires more effort and investment from utilities than simple standardization. For one thing, companies need specialized computer software that performs dynamic scheduling in real time. They must also switch to paperless systems and digitize asset data so that workers can communicate task information electronically.

Stage 4: A Digital Field Force

A fully digitized field force environment, complete with connected sensors, artificial intelligence, and augmented reality solutions, can substantially increase a utility’s efficiency while lowering costs. This ultimate level of digitized workforce management requires fewer people to perform tasks, with scheduled network inspections becoming a thing of the past. Instead, sensors enable technicians to monitor the health of the electricity grid or gas pipeline network and direct robots and drones to perform field checks. Companies can cut corrective maintenance in half by using alarms that signal when parts of the system become overloaded. Such real-time data also allows companies to make better investment decisions about equipment maintenance and replacement.

With digital, utilities can cut corrective maintenance in half.

Using augmented reality technology, skilled technicians at the operations center guide field crews through complex network faults, speeding up response times. Virtual and augmented reality technologies (which can highlight safety considerations on a user’s screen) can also bolster staff training and safety.

Companies aiming for full digitization should be prepared to invest significantly, with both money and time. After all, they’ll need capabilities to collect and analyze huge amounts of data: a typical medium-sized energy network firm generates about 60 million data items each day from the field. This requires upgrading and integrating existing software systems that govern operations, network and outage management, and workforce management to achieve a seamless, real-time information stream.

But how, exactly, can utilities move through the stages we’ve just outlined to reach full digitization in their workforce management? Read on.

Toward Digitized Workforce Management

Replacing legacy workforce management practices typically involves a lengthy and complex process, requiring careful planning from the outset. Nevertheless, with the right approach, utility companies can achieve significant benefits. Even before shifting to major new IT systems, companies can progress to more standardized or optimized procedures. To increase their chances of success and maximize advantages, company leaders should consider the following measures.

Identify Appropriate Targets

Before investing in new systems, weigh the costs and the benefits. Most likely your company shouldn’t target full digitization right away, but instead progress gradually. Companies in the beginning stages of transforming their workforce management systems will benefit most by standardizing and optimizing their processes.

The good news is that by delaying large, expensive investments, your company will benefit from lower prices in the future. Purchase costs have already declined sharply: ten years ago, a mobile communications system for a field force of 1,000 workers cost more than $10 million. Today, utilities can buy the same system for about $5 million. More targeted solutions that meet specific needs can be far cheaper and still deliver significant benefits. For example, your company can purchase a spreadsheet-based scheduling tool or develop a simple scheduling package for less than $1 million.

Choose an IT Solution That Supports Your Digital Ambition

Consider your company’s current information technology and operational technology requirements with an eye to aligning data-centric computing and process monitoring capabilities. One option: invest in a fully integrated IT system that supports standardized data collection, analysis, and reporting across several parts of the business and includes specific workforce management modules.

Utilities might also choose to develop or purchase software products tailored for individual tasks, such as dynamic scheduling. While this is likely the most inexpensive and least time-consuming option, it requires a robust interface layer linking the new software to existing systems.

Our work with leading utilities revealed that companies still in the midst of standardizing their workforce management procedures should pause before adopting a comprehensive integrated software suite. Instead they should develop or purchase targeted workforce management software solutions. This way, they will gain valuable experience for when they adopt more advanced digital solutions—including identifying requirements, implementing new processes, and redefining worker roles.

Some utilities should pause before adopting a comprehensive integrated software suite.

Allocate Sufficient Time and Resources to Your Transformation Program

Companies aiming to achieve best practice should establish a full workforce management transformation program, rather than pursuing piecemeal changes. As a first step, benchmark the quality and costs of your current procedures against peers, and identify the most pressing areas for improvement. You should also run pilot programs in individual regions to test changes to priority areas of the business. This will help identify potential savings and the feasibility of proposed procedures.

Next, develop a detailed plan that establishes goals across the company, lays out a roadmap for achieving them, and appoints a dedicated implementation team. Because the process involves significant changes to employees’ roles, you will need to consult with workers’ representatives. Companies should allocate 6 to 12 months to make major changes to existing systems and a further 6 to 18 months for changes to become embedded as viable systems. Securing quick wins alongside large-scale transformations will help maintain momentum and demonstrate success. Support the change process with a small but active project management team to ensure targets and milestones are fully met.

Allocate 6 to 12 months to make major changes to existing systems.

Offer Your Workforce Incentives for Change

Clearly, the kinds of workforce management procedures we’ve described will radically alter the workplace for employees. Field staff will get assignments and other task information remotely, through handheld devices; they will work with augmented reality goggles and communicate with the operations center using tablets; their performance will be scrutinized more closely; and they will spend more time in the field and less time traveling or at the center.

More efficient workforce management also means more savings and fewer staff needed to perform the same work. But it doesn’t have to mean immediate layoffs. Consider employing your new “spare” workforce to tackle the following important areas:

- Cut the backlog of outstanding tasks by proactively maintaining the network, reducing the risk of future failures.

- Save fees previously paid to external contractors by using employees to carry out a portion of contractor jobs. Companies should, however, still consider retaining contractors for some tasks. This will not only allow you to better manage peaks in workload but also give you a useful benchmark to gauge the productivity of your own workers.

At some point, however, the efficiencies of digitization will demand staff reduction. The following best-practice measures will help you manage layoffs:

- Decide how many employees you will need over the coming decades, and plan accordingly. In several developed markets, there is a shortage of skilled technicians who are willing to work in the field. Companies therefore may want to keep surplus staff to maintain a minimum level of workforce skills in the long term.

- While a hiring freeze is effective in cutting staff numbers, companies should treat it only as a temporary solution since a sustained stop on recruiting is also likely to lead to a shortage of necessary skills in the future.

- Use transparent and robust metrics to demonstrate differences in individual performance, justify the laying off of perpetual laggards, and reinforce performance targets for the remaining staff.

Given the impact of the changes that come with digitization, you will need to communicate with your staff to bolster morale, often and in detail. Let employees know the goals of the transformation, the progress made with different initiatives, and the successes won. To motivate workers, revamp organizational targets and key performance indicators, and align individuals’ personal targets and remuneration with those.

Digital workforce management solutions are revolutionizing how utility companies organize and execute field work. To achieve high-quality, sustainable results as they move toward full digitization, managers should identify a strategy and IT solution that best fit their organization. They will also need to spend the time and effort required to change existing workforce practices and attitudes. By adopting an evolutionary approach that includes the standardization and optimization of existing processes, they can manage their workforce efficiently far into the future.