In recent years, consumer packaged goods (CPG) companies have started to use zero-based budgeting (ZBB) to attack their costs . These initial efforts have typically focused on indirect spending categories related to selling, general, and administrative expenses. Costs in the supply chain have received less attention. We believe it is time for that to change. ZBB offers CPG companies the means to achieve step-change improvements in supply chain performance.

CPG companies have traditionally sought to reduce supply chain costs by 2% to 5% a year. Incremental reductions are no longer sufficient to withstand the pressures of today’s business environment; companies must make fundamental changes to their supply chain cost base while improving service and driving growth. However, at most CPG companies, the organizational setup and capabilities impede efforts to execute and sustain transformative cost reduction programs. When implemented effectively, ZBB provides mechanisms and instills mindsets that help overcome these challenges.

To apply ZBB in supply chains, commercial and supply chain teams must align their strategies and decide which costs can be addressed using ZBB and which cannot. This “handshake” enables the creation of an effective program based on an end-to-end perspective supported by digital analytics. A cultural shift toward greater accountability and continuous improvement is also essential. Companies can reinvest the savings they generate into initiatives that promote even greater value in the supply chain. Companies have already begun applying ZBB to their supply chains in other industries, including industrial goods, retail, and pharmaceuticals.

The Challenges of Reducing Supply Chain Costs

CPG companies face an imperative to grow rapidly at the same time that order lead times are shrinking, demand volatility is rising, and trucking capacity is increasingly constrained. These pressures, among many others, are driving complexity across the end-to-end supply chain, the effects of which can be seen in SKU proliferation, high rates of forecasting errors, and declining efficiency of production plants. Annual supply chain benchmarking studies jointly conducted by BCG and the Grocery Manufacturers Association have found that the impact of rising complexity is significant: from 2016 through 2018, it contributed to an increase of about 6% in logistics costs and an approximately two-day increase in inventory, while service levels fell by around 3%.

Companies’ efforts to reduce supply chain costs in response to these pressures have been impeded by a variety of organizational challenges:

- Disconnect Between Commercial and Supply Chain Strategy. At many companies, the commercial organization and the supply chain organization fail to collaborate on a mutually beneficial strategy. Instead, the commercial organization expects that the supply chain organization will focus on executing the commercial strategy. This frequently leaves companies with a reactive and suboptimal supply chain model across products, customers, and regions.

- Siloed Operations in the Supply Chain Organization. Within many supply chain organizations, various functions (such as logistics, planning, manufacturing, and sourcing) operate independently. Each siloed function seeks to optimize its own budget, without regard to the impact on other functions or end-to-end costs across the supply chain. Organizations typically focus on capturing supply side value, with a heavy emphasis on reducing procurement costs.

- Limited Data Visibility Across the Supply Chain. To identify the root causes of high costs and promote effective decision making, granular data is essential. Yet companies typically lack the detailed data necessary to understand what is happening at a transactional level in the supply chain. Even if they do possess the data, they often fail to use it effectively. Moreover, data collection and analysis tend to be labor-intensive manual processes, which often aren’t completed in time to allow for effective actions.

- Poor Execution and a Lack of Cross-Functional Routines. Employees at many companies are not prepared, capable, or incentivized to drive the transformational changes necessary to achieve and sustain significant improvements. Organizations also often fail to provide effective cross-functional routines that enable supply chain and commercial teams to collaboratively solve problems.

How ZBB Promotes Significant and Sustainable Value

ZBB entails resetting the budget each year, taking a bottom-up approach that is anchored in the planning process. The approach has many elements, including agreeing on the nature of costs, deciding where to reinvest, gaining transparency on actual expenditures, and establishing dual ownership of costs by category owners and budget owners. With a ZBB program, the company challenges the current way of working, rolls out policy changes, renegotiates prices, aligns targets, launches quick wins and larger initiatives, and implements tracking tools.

ZBB brings a new mindset to supply chains that emphasizes collaboration across all supply chain functions and the entire ecosystem.

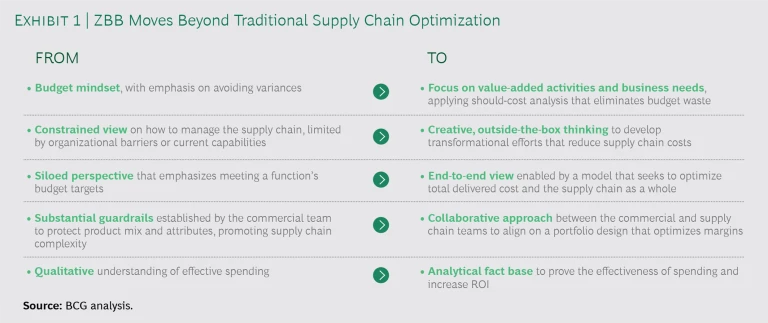

ZBB brings a new mindset to supply chains that emphasizes collaboration across all supply chain functions and the entire ecosystem. This approach allows an organization to capture benefits that extend beyond those available through traditional supply chain optimization. (See Exhibit 1.)

In our experience, companies must take five steps to successfully apply ZBB in the end-to-end supply chain—and make the changes stick.

Align commercial and supply chain strategies. The commercial and supply chain organizations must agree on their priorities with respect to cost, service, flexibility, and speed. The commercial organization provides input on where to play and how to win, including the customer and consumer strategy, the category, assortment, and product launch strategy, as well as on acquisition plans. The supply chain organization provides expertise on striking a balance among total cost to serve, service levels, working capital, and the ability to react quickly.

This handshake between commercial and supply chain teams is critical to enabling data-driven definitions of performance targets for ZBB. Although all brands and products are within the scope of ZBB, the commercial and supply chain teams must reach a consensus about guardrails that protect the customer value proposition of specific brands and products. For example, the value proposition of a soft drink might be damaged if the formula is changed in order to standardize the ingredients used in the company’s products. In contrast, the soft drink’s packaging (the bottle or can) may be open for discussion on applying ZBB strategies, because the packaging specifications may have less impact on brand equity.

The commercial team identifies the need for guardrails in specific cases. Then, the supply chain team has the opportunity to challenge whether guardrails, which may impede efforts to reduce cost and complexity, are indeed required to protect brand equity. If the supply chain team believes the guardrails are not necessary, it can challenge them effectively by providing the commercial team with better transparency into costs and a greater variety of choices. The teams can use analytics to evaluate how standardization would affect cost and brand equity, and then balance the tradeoffs.

The alignment of commercial and supply chain strategies also allows the company to segment the supply chain and differentiate performance and cost targets by product and customer.

Optimize from an integrated, end-to-end perspective. To optimize supply chain costs, companies should apply an integrated view that looks at total cost from product development through last-mile delivery. An integrated view considers interdependencies and cost tradeoffs across a wide range of value levers in product development, demand and supply planning, sourcing and procurement, manufacturing, and distribution. Some value levers deliver short-term savings to fund the ZBB effort.

Apply automation and digital analytics. The application of automation and digital analytics is critical to reducing costs associated with labor-intensive manual work, so that the company can identify and realize the dramatic improvements promised by ZBB. The company needs to develop a digitally enabled vision of the supply chain and then determine how to capture the cost reduction opportunities.

Automation and analytics can be applied in supply chains in a variety of ways. Examples include physical automation (such as using automated guided vehicles to transport products in a warehouse), digital capabilities that automate manual processes (such as demand forecasting), and advanced analytics that allow data scientists to find the root causes of high costs.

The following set of guiding principles helps ensure a high return on digital investments:

- Identify use cases for digital analytics that solve root-cause problems in the supply chain. Focus investments on technologies that enable use cases prioritized on the basis of returns, and gain executive committee support for investment decisions.

- Integrate data across functions to enhance the understanding of an investment’s potential impact and the total delivered cost.

- Apply agile ways of working in rapid pilots in order to demonstrate value and generate momentum and interest within the organization.

- Treat digital projects as you would an operational excellence transformation, such as by establishing a program management office and clear milestones.

Instill a new culture and manage the transition. Companies must take steps to promote employee accountability and enable continuous improvement through ZBB. To ensure ownership and an end-to-end view, they should establish top-down governance and a ZBB project management team with members representing each supply chain function and the commercial team. Regularly scheduled meetings provide a forum for supply chain participants to review total delivered should-cost analyses, brainstorm ZBB ideas, prioritize ZBB initiatives, and track value capture. To manage initiatives, the team needs clear metrics and incentives, as well as clear accountabilities for meeting targets. For example, the sales function and the demand planning group could have joint accountability for forecast accuracy.

Companies should reinvest savings from ZBB in big-bet supply chain initiatives that promote significant value.

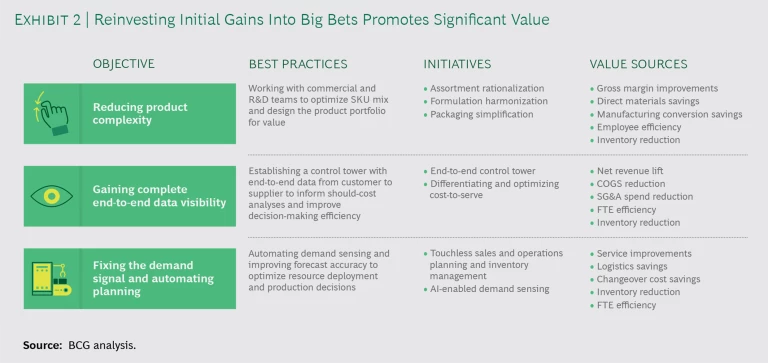

Reinvest savings. A company should pursue quick wins to rapidly realize the initial savings from ZBB. It should reinvest these savings in big-bet supply chain initiatives that promote significant value. Priority areas in which to reinvest include reducing product complexity, gaining full visibility of data from end to end, and improving supply planning and forecast accuracy. (See Exhibit 2.)

Companies have used this approach to achieve substantial reductions in the addressable cost base of direct materials (6% to 10%), operating expenses (20% to 22%), and logistics (22% to 24%). The impact has also included a 15% to 30% reduction in inventory and a 2% to 4% increase in EBITDA.

Getting Started

To lay the groundwork for applying ZBB in supply chains, a company needs to first establish a deep understanding of the fact base. It must also form a cross-functional team to develop the ZBB initiatives and define targets. The team should assess the state of supply chain technologies that support ZBB and gain an understanding of how the technologies are expected to evolve over the next five to ten years. Once the company is ready to launch the program, it should begin by addressing key areas prioritized on the basis of speed to impact and size of impact. The time frame from assessing the opportunities to scaling up a program is usually six months to a year.

ZBB gives CPG companies the mechanisms and mindsets they need to reach the next horizon in supply chain performance. The philosophy and ambition of ZBB unlocks value in a variety of ways, including cross-functional collaboration and alignment, a culture of improvement, and reinvestment of returns to promote further savings. Companies that bring to bear the right techniques, tools, and operating model will be rewarded with a supply chain that delivers superior performance at lower cost.