The next decades will be critical in the worldwide effort to combat climate change. Unless we can substantially reduce greenhouse gas (GHG) emissions globally and permanently, we have little chance of limiting the increase in average global temperatures to 2°C or less by 2050, a key tenet of the 2016 Paris Agreement. If we don’t meet these goals, the consequences for the world’s economies will be severe .

Right now, we have the technical means to reduce a major portion of the estimated 51 gigatons (Gt) of GHG emissions released into the atmosphere each year, and machinery and equipment manufacturers have a key role to play in the effort. Already, they supply the renewable-power generation equipment, optimized heating and cooling systems, highly efficient motors, and other technologies needed to reduce a substantial portion of our GHG emissions. Gaining the full benefits of this equipment will require a considerable investment from clients—around €10 trillion through 2050. That’s about a third of €1 trillion per year—but still a mere drop in the bucket compared with the annual global GDP of €76 trillion.

It is up to the machinery suppliers to develop the green technologies needed in the fight against climate change.

Developing and deploying those technologies that are technically possible but still too costly to use at scale (such as greener fuels and carbon capture), will be a far more difficult task. But machinery and equipment providers willing to take on the challenge stand to gain a significant competitive advantage over slower, less progressive rivals.

In this report, we examine the role of machinery manufacturers in providing the equipment and expertise needed to meet our GHG reduction goals. By analyzing the relative amount of GHG emissions produced by each of the industrial sectors that purchase and use these manufacturers’ products, and the specific technological levers the manufacturers themselves can pull to contribute to the effort, we can gauge the broader impact these actions have in reducing our global total. It is up to the machinery suppliers to develop the green technologies needed in the fight against climate change. For them, the potential upside is massive.

ACCOUNTING FOR GLOBAL GHG EMISSIONS

According to the United Nations, global GHG emissions came to 51 Gt of CO2-e in 2017, of which the 36 countries we analyzed emitted 35 Gt (the “total” referred to throughout this report)

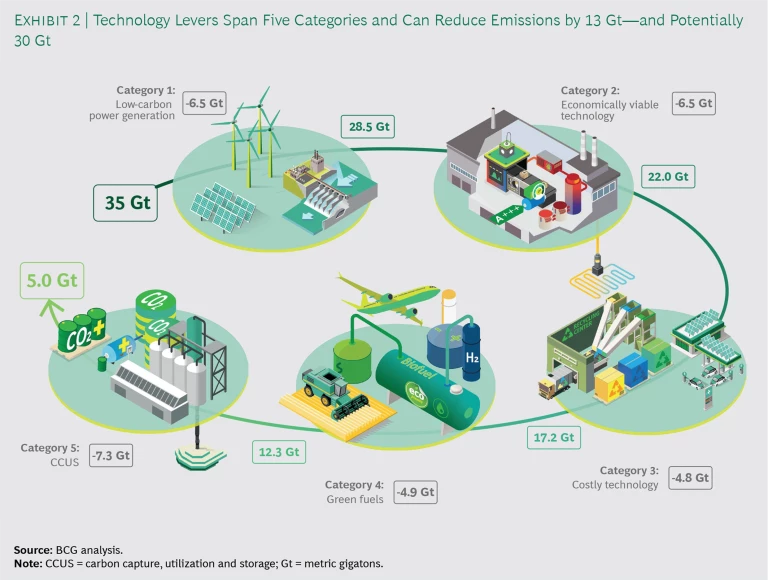

Our analysis shows that 37%, or 13 Gt, of the 35 Gt total can be reduced by existing technologies that are economically feasible today. Another 49%, or 17 Gt, can be mitigated with technologies that are feasible but not yet economically viable, including green fuels and carbon capture techniques. This brings the reduction potential to 86% of the total.

Every industry sector emits two kinds of emissions:

Scope 1 includes all the emissions produced by companies in the course of their operations. These can be broken down further into “process” and “energy” emissions, the former of which include all GHGs emitted as part of company activities, such as the CO2 produced in the processing of iron to make steel and the methane produced by cows in agricultural production. Scope 1 process emissions account for 29%, or 10 Gt, of total emissions. Energy emissions include the emissions companies produce to generate the heat, electricity, steam, and other power sources they use in their production activities. These account for 44% of the global total, or 15.2 Gt. Note that virtually all the emissions produced by transportation, including cars, trucks, planes, trains, and ships, fall into this category.

Scope 2 includes all emissions produced by energy-generating companies that are then bought and used by companies in other sectors. Power generation accounts for 27% of total emissions, or 9.5 Gt.

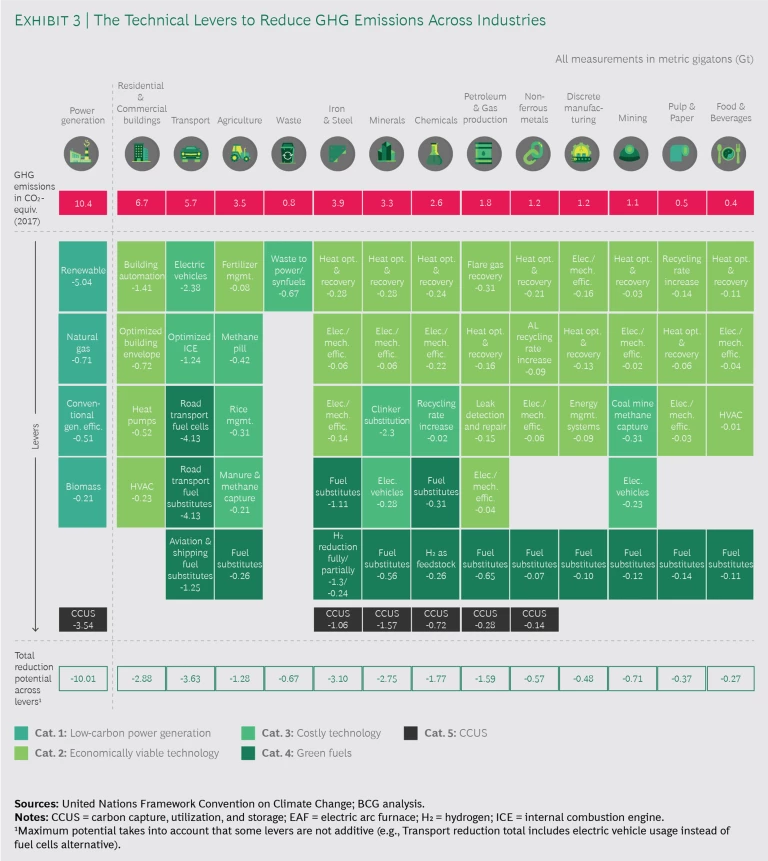

Companies from almost every industry have a variety of existing technological levers they can use to reduce their carbon footprint.

Globally, manufacturing produces 48% of total emissions: 6 Gt of Scope 1 process emissions, 5.7 Gt of Scope 1 energy emissions, and 5 Gt of Scope 2 emissions. Among manufacturing subsectors, iron-and-steel producers are the largest contributor, at 3.9 Gt. Minerals companies follow with 3.3 Gt (mostly in the production of cement, but also in making ceramics and glass). Chemicals companies come third, at 2.6 Gt.

Nonmanufacturing sectors produce the remaining 52% of the total. Aside from the power generation sector, residential and commercial buildings produce the most (6.7 Gt), followed by transportation (5.7 Gt) and agriculture (3.5 Gt). (See Exhibit 1.)

The power generation industry is a special case. It alone produces 10.4 Gt of GHG emissions, or 30% of the total. The industry creates just 0.9 Gt of Scope 1 emissions to maintain operations, but it creates 9.5 Gt of emissions in the course of producing the power it sells. We attribute those emissions to the customers to which the industry sells its power; the GHG emissions these customers produce is therefore equal to all the Scope 2 emissions created during the consumption of energy by all the other sectors combined.

Gaining Leverage

Companies from almost every industry have a variety of existing technological levers they can use to reduce their carbon footprint, from electric vehicle usage to green fuels (such as hydrogen), of which some are not yet fully developed for most industries. In order to determine which of these levers will produce the greatest impact on the GHG emissions attributable to each sector, and how machinery manufacturers can contribute to the effort to lower those emissions, we analyzed the technical feasibility of all existing carbon-reducing technologies. We did not account for how widely available the technology is at present, how quickly it could be installed at scale, or the willingness of companies to deploy it given their installed base of current technologies.

Each technology’s economic viability depends on whether it has developed to the point where companies would be willing to implement it today, or if it is still too costly to deploy at scale.

The emissions-reducing technology levers can be grouped into five categories, with placement depending on the nature of the levers, as well as their technical and economic feasibility. (See Exhibit 2.) Efforts to carry out the first two categories have already begun—although much work remains to capture their full potential. For the most part, the others will have to wait until their implementation becomes both technically possible and economically practical on a broad scale. Still, regardless of their technological maturity, efforts to develop and perfect them can and should begin immediately. There is no reason that our five categories should follow a strict sequential order. Exhibit 3 summarizes the technological options available to each industry in reducing its carbon emissions along these categories.

Category 1 levers include only those technologies that can enable the power generation industry to reduce its own emissions. This category is critical if we are to reach our climate goals, since the power industry emits an enormous portion of total GHGs, at 10 Gt annually. The lever in this category with the greatest potential for GHG reduction is renewable power generation, which could, in theory, entirely decarbonize the power generation industry. Given the practical limits of its use, however, it is estimated that renewables could replace 5 Gt of GHGs each year

Category 2 levers include the economically viable technologies that could be used currently to reduce emissions in all manufacturing and nonmanufacturing sectors. The primary levers in this category, available to almost every industry, are heat-optimization-and-recovery technologies (which could reduce 1.8 Gt of GHGs) as well as increased electrical and mechanical efficiency (0.8 Gt). Other, sector-specific emission reduction levers also have a role to play

Category 3 levers cover those technologies that, while currently available in some form or another, are not yet viable due to cost or because they can’t yet be scaled to the point where they would make a significant difference. These include methane capture in agriculture and switching entirely to electric vehicles in the mining and minerals sector.

Category 4 and Category 5 levers include green fuels, such as hydrogen and biofuels, and carbon capture, utilization and storage (CCUS) technology, that all have the potential to be real game changers in emissions reduction efforts, although many are not yet technologically or economically practical. When applied to the Scope 1 emissions that remain after pulling the category 2 and category 3 levers in every sector, green fuels could potentially reduce emissions by a total of 4.9 Gt annually, and CCUS technology by a total of 7.3 Gt.

The Opportunity for Machinery Makers

Each of the five categories offers a wide range of actions that companies in industrial sectors can take to participate in the global effort to reduce GHG emissions. For us to achieve the goals of the Paris Agreement, companies from every industry will have to use the full range of technologies at their disposal. (See “Collective Action”.)

COLLECTIVE ACTION

COLLECTIVE ACTION

Levers that are economically viable now should be pulled as soon as possible; those that aren’t will need to be supported until they are. Those that are not yet technically feasible must be developed and deployed once they mature.

Ensuring the economic viability of current and future technologies will depend largely on the degree of commitment by multiple stakeholders to the goal of reducing GHG emissions:

- Governments. The most important factor in this effort will be the willingness of the international community to stick to global climate goals. All governments can accelerate the effort by determining strict pricing mechanisms for GHG emissions and offering temporary support for the deployment of new GHG reduction technologies.

The EU, for example, recently announced a plan to renew and reinforce its efforts to become entirely carbon neutral by 2050. Called the Green Deal, it gathers together a variety of sustainability goals—including zero pollution, a circular economy, a just and inclusive energy transition, and others. Key to the effort is positioning the EU for technological leadership to reduce carbon emissions as a trigger for sustained economic growth. The plan is estimated to require approximately €300 billion in additional investments annually over the next decade for the infrastructure needed to meet these goals—a significant further opportunity for machinery makers.

Governments should also support the long-term goal of ensuring predictable price differences between fossil-fuel-based and climate-friendly energy generation, as well as foster a supportive environment for investment in the technology needed for hydrogen-fueled transport and electricity transmission and distribution. - Investors. Investors are already increasingly demanding transparency in their companies’ GHG emissions practices and investing in companies with clear, climate-friendly strategies for reducing their emissions. Some are considering applying a risk premium for companies with potentially stranded assets that may become unprofitable in a more sustainable future.

- Businesses. Private-sector enterprises can increase the pressure on their partners and suppliers to make their GHG footprints more transparent, adopt economically viable technology early on, and even be willing to pay a premium for components, feedstock, and services produced using low-emissions standards and processes.

- Society at Large. The public must be willing to accept and support all efforts to reduce carbon emissions, including more controversial technologies such as the long-term storage of carbon in deep-sea waters or former oil and gas fields.

This is unlikely to happen immediately. However, by pulling the currently more feasible levers in the first two categories alone, we can reduce total emissions by 37%. We estimate that pulling all the levers in categories 1 and 2 will require total capital expenditures of €4.5 trillion into machinery and equipment over the next decade. (This estimate does not take into consideration the cost required to operate the equipment once it is installed.)

The next three categories will only grow in importance, feasibility, and productive value in subsequent years, and they will require investments of an additional €5.9 trillion in new machinery and equipment through 2050. This brings the total investment needed to complete all five categories to €10 trillion. Exhibit 4 breaks this down into the overall investment potential for each technology category.

A category-specific analysis reveals the levers that can be pulled in each category for every industry covered, the specific role of machinery makers and related technology providers in helping clients and potential clients pull them, and the potential size of the investments needed to deploy these technologies.

Category 1: Power Generation Levers

The sole goal of category 1 is to reduce the GHG emissions released by the global power industry in the course of generating electricity. If all the levers in this category alone were to be pulled, the industry’s emissions would decline by 6.5 Gt, a reduction of almost 20% of our global total.

By far, the most important action involves shifting to renewable sources of power generation—primarily solar and wind power—which would reduce emissions by 5 Gt if 49% of energy production were converted to these sources. Renewable power generation has already proven to be technically feasible at scale, and it is already cost competitive with fossil-fuel-based methods, so expanding the use of renewable sources would be economically viable

Still, if we are to reach the goal of reducing emissions from power generation by 5 Gt, the worldwide use of solar photovoltaic power systems will have to increase by 800% over the next ten years, while the use of wind generation must increase by 400%. The effort to increase the use of these power sources will require significant investments in machinery and equipment—an estimated €2.3 trillion through 2030.

The largest share of this investment potential, approximately €1.1 trillion, will go to solar energy, the cost of which is also expected to decline the most. Wind energy will likely capture the second-most investment (€820 billion), followed by hydroelectric energy (€360 billion). How much of this potential revenue will be unlocked depends on multiple factors, including the regulatory conditions regarding the share of renewables in the power mix and public acceptance of wind farms and hydroelectric dams.

Equipment suppliers have a major role to play in the development and deployment of these systems—and a major opportunity to increase revenues. Moreover, technologies for boosting the flexibility of the power grid and improving storage capacity (not included in this analysis) will lead to further revenue opportunities.

In addition to renewable power sources, the power generation industry has several other levers it can pull. Increasing efficiency at its plants, upgrading to highly efficient, modern combined-cycle gas power plants, and the use of biofuels under certain circumstances would together reduce another 1.4 Gt of carbon emissions. Here, the opportunity for technology providers lies in carrying out upgrades of gas and biofuel plants and supplying high-efficiency motors.

Decarbonizing the power sector is especially critical because global demand for energy is expected to keep growing for the foreseeable future. The production of synthetic fuels (synfuels) such as hydrogen, while not yet economically viable, will place an enormous burden on the electrical grid. For example, increasing the share of synfuels in road transportation in Germany to 25% would result in an estimated 70% increase in demand for electricity nationally. And converting hydrogen to a useable fuel requires electrolysis, a further drain on the grid.

Category 2: Technically Feasible, Economically Viable Levers

This category covers all the levers that could be deployed today across industries, offering machinery makers a wide range of opportunities for providing customers with the means to reduce their carbon emissions. For these companies, the revenue potential is a considerable €2.2 trillion opportunity. A good portion of this investment potential is likely to become a reality due to the associated cost savings to be gained by implementing these technologies. If fully deployed, they have the potential to reduce emissions by 13 Gt annually. The following options are most feasible.

Heat Optimization and Recovery. Widespread implementation could reduce GHG emissions by 1.8 Gt and offer revenue opportunities of €580 billion for machinery makers. These technologies can be deployed in every manufacturing industry, especially in applications where the recovery of waste heat has so far been neglected. And because they lead directly to cost savings in energy consumption, their return on investment for manufacturers is immediate. As a result, they will likely be among the very first levers to be pulled by companies committed to low-carbon production methods.

Investments in heat exchangers, the core technology for recovering heat, will likely constitute the largest share of these investments. Other technologies include high-efficiency burners that preheat the air and fuel to enable them to operate more effectively, systems that send waste heat from exhaust gases to nearby consumers of heat, and heat pumps that raise the temperature of waste heat to levels needed in other production processes. In addition, effective heat storage technologies can store waste heat and send it to consumers when needed.

Considerable growth opportunities exist in the further development and production of heat optimization and recovery capabilities.

Considerable growth opportunities exist in the further development and production of heat optimization and recovery capabilities. According to one machinery manufacturer that caters to the beverage production industry, the use of waste heat and heat storage systems can save up to 60% of the thermal energy required by breweries.

Building Automation. Building management systems that control heating, cooling, ventilation, and shading and lighting (both automatically and on demand) have the potential to lower carbon emissions by 1.64 Gt. Regulating a building’s temperature, air quality, and lighting depending on when it is occupied can reduce energy costs by up to 40%, especially in commercial buildings, whose occupants are typically less inclined to try to save energy when someone else is paying for it.

Taken together, these various technologies offer machinery companies a revenue opportunity of about €1.1 trillion. The most important include efficient HVAC systems, automation systems (from simple, standalone thermostats and timed switches to the most advanced automation equipment), building management systems that bring together a range of building maintenance functions, and systems that manage and monitor energy performance.

All manufacturers can benefit from the devices needed to boost the electrical and mechanical efficiency of their production equipment.

Building-automation technologies will likely be implemented quickly in the coming years, given their immediate effect on energy costs. Technology providers can participate in the transition in several ways. Measuring and networking equipment will be needed to monitor conditions inside buildings. Automation equipment such as actuators for controlling windows, blinds, and HVAC systems will be needed to optimize heat and energy use and storage. The deployment of heat pumps and peak load heaters will also increase significantly. Finally, there is all the equipment required to produce advanced insulation materials in addition to double- and triple-pane glass windows. However, the effectiveness of these technologies varies considerably depending on the building’s local climate conditions.

Process and Equipment Optimization. All manufacturers can benefit from the devices needed to boost the electrical and mechanical efficiency of their production equipment, which in total can reduce GHG emissions by 0.8 Gt. To reach that goal, these technologies, the majority of which have already proven effective, must be fully rolled out across industries. The potential decline in emissions will come through significant reductions in energy consumption, and the resulting savings will likely make them especially attractive to manufacturers. Pursuing cross-technical technologies can support this effort.

The use of highly efficient motors that produce the same mechanical power while consuming less electrical energy, as well as efficient distribution transformers, can achieve real energy savings. Moreover, most electric motors in industrial applications, such as pumps, compressors, and fans, run constantly at full speed. This is highly inefficient in most applications since the demand placed on these motors varies considerably and is usually much lower. Electrical motors with variable-speed drives and intelligent controls that detect demand and operate accordingly can reduce electricity consumption by up to 40%, resulting in extended lifetimes and decreased noise.

But even the most efficient motors can’t reach their full potential if their design isn’t suited to their application. Greater cost savings can be achieved when the designs of pumps, compressors, fans, and other motors precisely match their respective applications. Machinery makers therefore have a big opening to manufacture all connected mechanical equipment with the same degree of efficiency.

Meeting the goal of reducing emissions by the full 0.8 Gt will require an estimated €230 billion in investment, with most of the opportunity for the machinery industry coming through the supply of variable-speed drives.

Recycling. Increasing the recycling and reuse of all kinds of materials offers many benefits, the most important of which is reduced need for sourcing and raw materials usage. But the so-called “circular economy” can also help reduce GHG emissions, primarily because producing goods with recycled materials is far less energy- and process-intensive than using virgin materials. There’s no need to mine, smelt, and ship iron ore for steel if it can be produced from scrap.

Our analysis of the reduction in GHGs to be gained through recycling focuses on the iron and steel, aluminum, and pulp and paper industries, and on the production of plastics in the chemicals industry. Pulling category 2 levers across these industries would lead to a decline in emissions of 0.5 Gt. Furthermore, recycling plastics has the added benefit of reducing the pollution created by its improper disposal.

Recycling is already economically viable in the iron and steel, aluminum, and paper industries.

The quality of recycled end products depends greatly on the homogeneity and cleanliness of the recycled materials, especially for plastics. It is critical, therefore, that the materials to be recycled are carefully sorted and separated into what’s useable and what isn’t. The machines needed for these operations are largely available, and demand is increasing.

Recycling is already economically viable in the iron and steel, aluminum, and paper industries, but recycling many types of plastics is not yet economically competitive and needs to be subsidized. Technology providers should nevertheless consider further developing the equipment needed to improve its viability to take part in an attractive growth market.

Heat Pumps. Current state-of-the-art heat pumps use three units of heat from the surrounding ground heat or air, and one unit of electricity, to produce four units of heat. That is far less energy than the typical gas boiler, which requires four units of energy from natural gas to produce the same amount of heat. Yet most of the heat generated for homes and other buildings today comes from the energy produced by burning fossil fuels, such as natural gas.

A heat pump’s efficiency depends on two factors: the temperature of the surrounding input heat and how the heat produced is distributed. Heat pumps are already economically viable in new buildings, but less so for buildings that need retrofitted, as the new ground-based heat sources and low-temperature space heating systems typically needed can be expensive. Still, technology providers can benefit in either scenario. Switching to heat pumps, together with the decarbonization of the power generation sector that supplies their electricity, can reduce emissions by 0.5 Gt. Supplying the need would provide €290 billion in revenue for the machinery industry.

Flare Gas. Approximately 150 billion cubic meters of petroleum gas are vented or burned off as flare gas in the course of oil and gas exploration and extraction, according to World Bank estimates. Unburned gas is mostly methane, a particularly potent GHG, while flare gas releases CO2 when burned. Switching to flare gas on a global scale would cut emissions from the oil and gas industry by 0.3 Gt.

In addition to lowering their GHG emissions, oil and gas companies can profit from the capture of flare gas, which can be reused on site or sold as fuel or feedstock for chemicals without the need for expensive refinery equipment.

The additional profits should provide an incentive for these companies to install equipment for capturing, processing, and transporting flare gas—and an incentive for technology providers to supply the equipment.

Leak Detection and Repair. Gaseous hydrocarbons also leak out in the course of petroleum and gas production. Reducing these emissions by 40% would save 0.15 Gt of GHGs. But detecting leaks requires special equipment, such as satellites and infrared cameras, and while the equipment needed to repair leaks is inexpensive, the labor costs can be high. Manufacturers looking for opportunities in this area should also consider offering their own monitoring and repair services.

Precision agriculture technologies can be used to reduce GHG emissions even further.

Energy Management Systems (EMSs). The ability to monitor and benchmark energy consumption can enable companies in every manufacturing sector to identify significant potential reductions. EMSs allow them to compare their own experience with best-practice KPIs and to monitor usage trends. Thanks to the associated cost savings, EMSs are already economically viable and can save up to 10% of a company’s total consumption; on a global basis, they could reduce total emissions by 0.09 Gt (the figure does not include emissions reductions achieved through efficient equipment and intelligent operations, which are accounted for in other levers).

Here, equipment manufacturers can benefit in several ways: by developing and selling the technology itself; by providing the technologies for further reducing emissions revealed by EMSs; and by leveraging their benchmarking and experience with other customers to sell additional EMS services and audits.

Efficient Fertilizer Management. Farmers worldwide release a considerable amount of GHGs (mostly nitrous oxide) into the atmosphere when using natural fertilizers, such as liquid manure. Managing their application could lead to a 0.08 Gt emissions reduction annually. Proper management can minimize the contamination of soil and water through excessive fertilizer use and save money in the process.

Many of these techniques are already economically viable. Technology providers can supply the measurement tools needed for determining the content of natural fertilizer and the nutrient concentration in the soil in their fields, as well as in the water they use to irrigate their crops. Precision agriculture technologies can be used to adapt the rate of fertilizer application to each field’s specific requirements, lowering the amount of fertilizer, capturing additional savings, and reducing GHG emissions even further.

Category 3: Technically Feasible, But Not Yet Viable Levers

This category covers all the levers that are not ready to be deployed today, either because they cannot yet be scaled up, or because they still cost too much. Capturing the full potential of these levers will depend on when they are ready for widespread use, which for most is unlikely without considerable government-backed financial and regulatory support. If fully deployed across all sectors, however, they could lower GHG emissions by 17 Gt.

Companies conducting the research needed for scaling can benefit further by spreading their R&D costs across several sector opportunities and as a result get more bang for their buck. The following levers should be considered.

Electrification of Vehicles. The emissions-lowering effect of substituting fossil fuels with electricity to power the world’s vehicles depends on the degree of the technology’s penetration; the total electrification of our global road transport system would reduce 2.4 Gt of GHGs annually. Achieving this, however, also depends directly on the complete application of category 1 reductions in the carbon intensity of the power generation industry.

There’s considerable potential in supplying components for BEVs, including batteries, electric motors, and electronics.

This lever is already available and economically productive in sectors where light-duty vehicles travel short distances—in local package delivery, for example. If electric vehicles are to reach their full emissions reduction potential, however, the charging infrastructure and battery production capacity will also need to be fully deployed. This is economically viable, in theory, but getting there will take considerable political support.

Still, converting existing auto plants to battery electric vehicle (BEV) production offers a market potential of around €1 trillion, assuming that BEVs will ultimately replace all other cars. There is also considerable potential in supplying components for BEVs, including batteries, electric motors, and electronics.

Optimization of Internal Combustion Engines. A 30% increase in the efficiency of the internal combustion engines that propel road vehicles can potentially reduce GHG emissions by 1.2 Gt. These gains can be made by increasing the efficiency of the engines themselves, as well as by advances in the equipment needed to produce lighter-weight vehicles and technologies for recouping waste energy, such as so-called “hybrid motors” equipped with regenerative braking.

The costs associated with the R&D needed to design and deploy these technologies, in addition to the costs of replacing all the internal combustion engines currently on the road, are considerable. Pulling this lever completely will require a significant financial investment as well as political and regulatory support—much like the government-mandated retrofitting of catalytic converters in the 1990s.

Reusing Waste Methane. As organic waste decomposes, it releases methane gas that can be captured to produce biomethane fuels that can, in turn, be used in numerous applications, including power generation, transportation, and heat production. Taking these steps on a global scale has the potential to reduce GHG emissions by 0.67 Gt.

Recycling waste methane is not yet economically viable, and it will likely take substantial subsidies and carbon-pricing regulations to increase its use. As the technology becomes more common, however, the tech providers will be instrumental in supplying the necessary equipment for the leak-proof facilities needed to store methane, as well as the anaerobic digesters and gasification and treatment plants for converting it to other uses. We estimate the market potential for these investments at €280 billion.

Coal Mine Methane Capture. The process of coal mining releases methane trapped inside the coal. In addition to the risk that it can explode, endangering miners, the methane released is a particularly potent GHG, and capturing it could reduce an equivalent of 0.3 Gt of emissions. The market potential for providing the technology for capturing this methane, pumping it to storage facilities and reusing it as fuel for heating or electricity generation, is around €20 billion.

Even partial substitution of clinker can reduce GHG emissions significantly.

Manure Methane Capture. Around 7% of GHG emissions released by the global agriculture sector come from the release of methane in the course of manure fermentation at manure management facilities. Capturing these emissions and reusing them to generate power and heat could reduce the industry’s emissions by 0.21 Gt. But capturing the methane and converting it to fuel at biorefineries is too expensive to make it economically viable at present. Technology providers should see this as an opportunity to develop and sell the equipment that would make it possible, within a potential €85 billion market.

Once this technology does become feasible, technology providers should also consider developing equipment for collecting manure in the field as an additional feedstock for biorefineries.

Clinker Substitution. The clinker produced during the production of cement used to make various cement products requires a tremendous amount of heat and creates an outsized proportion of all the GHGs emitted globally—fully 2.3 Gt every year. Avoiding its use by substituting other materials, such as steel slag, fly ash, or granulated blast furnace slag, can save 80% of that total.

The technology for clinker substitution is already being used, but its deployment is constrained by the lack of enough substitute materials. In addition, safety regulations in some jurisdictions are preventing the rollout of new clinker substitutes. But even partial substitution of clinker can reduce GHG emissions significantly. And as the process gains traction, companies can benefit from sales of current and future clinker substitution systems.

Methane Pills. Cows and other ruminants produce 0.4 Gt of total GHG emissions through the methane they emit. While it is by no means technically feasible yet, a methane pill is being tested in clinical studies that prevents the formation of methane during digestion.

However, it is unlikely that methane pills will ever be economically viable on their own, since there is no revenue or cost savings to be gained by giving them to livestock. Their use would therefore need to be subsidized or supported through CO2-pricing schemes. The opportunity for technology providers lies in developing and selling the equipment for producing the pills.

Rice Management. Rice is usually grown by flooding fields during the early season to limit the growth of weeds and pests, but the microbes that decay the organic matter left behind produce methane. As a result, the cultivation of rice accounts for 10%, or 0.3 Gt, of the total emissions produced by the agriculture sector.

Proper rice management can reduce those emissions by 90% through early- and mid-season drainage. Extensive work has been done to produce hybrids that require less water and increase productivity, but their value in large-scale applications has yet to be proven. Moreover, the opportunity for technology providers is low, since most of the world’s rice is grown in emerging markets such as Asia and Africa, where the money needed for further research is limited.

Category 4: Green Fuels

This category covers the technologies involved in the substitution of fossil fuels with green fuels made from hydrogen, biomass, and so-called “power-to-X” (P2X) fuels derived from the conversion of electricity. To help these alternatives reach their full decarbonization potential, the energy needed to produce green hydrogen and P2X fuels must come entirely from renewable sources. Therefore, both renewable power generation and the infrastructure required to produce and distribute green fuels must be in place before this lever becomes economically viable at scale. Once these initial hurdles are overcome, the benefits will span multiple industries and applications. These fuels could potentially reduce global GHG emissions by 4.9 Gt.

Technology providers can benefit by supplying what is needed to produce green fuels in multiple industries.

Technology providers can benefit by supplying what is needed to produce green fuels in multiple industries. We expect this market to total €2.1 trillion in potential revenue over the next decade. Opportunities include the construction of electrolysis plants to produce green hydrogen for use as feedstock in the chemical industry, which alone will be worth €410 billion in revenue.

They can also supply the technology and equipment needed to enable the substitution of fossil fuels for green alternatives in several industries. Building synfuel production capacity for the aviation and shipping industries alone—where electrification is not likely to be an option—will require a €1.1 trillion investment.

Other opportunities include using hydrogen for fuel cells in transportation and in other sectors, and as a reduction agent in the iron and steel industry. Hydrogen and synfuels can also replace carbon-based fuels for burner use in high-temperature applications. The market potential for providing the production capacity needed to replace natural gas with biogas or biomethane throughout all industrial sectors totals around €600 billion.

Category 5: Carbon Capture, Utilization and Storage (CCUS)

This category is dedicated to the use of CCUS technologies that capture, use, and store GHGs emitted during power generation and other industrial processes where the fossil fuels used cannot be economically replaced with green fuels, or in natural gas extraction. The technology has the potential to lower total emissions by 7.3 Gt, and extensive research is being conducted into the potential for converting captured carbon into synfuels. Alternatively, the carbon can be kept in long-term storage locations underground, or even in the ocean. But at scale, such possibilities will need to overcome both economic factors and safety concerns.

Still, there is growing interest in the technology. As of 2018, there were 43 commercial large-scale global CCUS facilities: 18 of them in operation, 5 under construction, and 20 in various stages of development. Most of these operations are being deployed at locations where large amounts of CO2 are emitted within a confined area, such as near power plants and other direct GHG emitters.

We must reduce emissions by another 17 Gt if we are to stem the impact of global warming.

Until technologies can be developed to derive more profit from the carbon CCUS facilities capture—or GHG emissions prices rise high enough to offset the cost—CCUS will remain a pure cost added to legacy infrastructure, and one that requires government incentives to make it economically viable. Furthermore, these facilities do not require much new machinery for their operation. Instead, their value lies in preserving the life cycle of the existing emissions-intensive machinery used in the processes of the operations where they are co-located, including the blast furnaces used in iron and steel production and the equipment used in coal-fired power plants—already a steeply declining market.

The economic viability of CCUS depends largely on the availability of storage facilities, on the cost to transport it, and on the purity of the gas being captured; the purer it is, the less costly it becomes to process it for other uses. Its viability therefore varies from industry to industry. Its viability for the chemicals industry (especially for the production of ammonium and petrochemicals) and natural gas extraction is rated as medium. But its viability is low in power generation and aluminum, cement, or iron and steel production. Thus, deployment of these facilities and the technology needed will depend on the economic viability of CCUS in each industry; still, the potential market revenue is estimated at €2.4 billion.

Next Steps

Machinery and equipment manufacturers are playing a large role in supplying the equipment and services needed to meet our GHG reduction goals globally. Already, they are helping cut back on the 13 Gt of GHG emissions that can be reduced by deploying technologies that are economically viable and available now.

Looking forward, however, we must reduce emissions by another 17 Gt if we are to stem the impact of global warming. This will be a much more difficult task, and one that is largely up to those same companies to develop and produce the technologies needed to get us there. They must look far ahead, anticipating the requirements of the industry sectors they serve as the need to reduce carbon emissions becoming even more pressing; thankfully, the potential for growth is significant.

To prepare themselves for ultimately capturing these growth opportunities, all machinery makers should take the following three steps:

- Reduce your own carbon intensity. Show your customers that you understand the urgency of decarbonization. Leading by example will also give you a competitive edge over your less committed rivals. This will involve understanding and maintaining evolving carbon reduction standards within your own industry. Become the first company in your industry to achieve true low-carbon production, which will be especially important as your customers grow increasingly conscious of the importance of reducing their own carbon footprints.

- Evaluate your product and service portfolio. Account for different climate change scenarios and the opportunities they offer and the risks they present. This will enable you to identify new green tech opportunities in previously untapped industries and applications—and to move quickly into new markets when the opportunity arises. It will also prepare you better to take advantage of the rise of truly disruptive new green technologies. The surprising speed at which LED lighting replaced incandescent bulbs, for example, has resulted in the rapid loss of competitive advantage for many top companies.

- Immediately develop the ideas that will lead to the products and services capable of mitigating your clients’ GHG emissions. Carry out R&D-based lighthouse projects to determine the technical and economic feasibility of these concepts, and start to upgrade your portfolio, either organically or through strategic acquisitions.

Mitigating the effects of climate change is everyone’s job, and companies everywhere can help by reducing the GHG emissions they are responsible for.

Train your service professionals to look for potential efficiency gains to be made at the factories and facilities they visit, ensuring that they report back regularly with new ideas and potential opportunities. Consider also training service professionals to provide energy-efficiency consulting services to clients on site. Finally, showcase to potential clients the gains in decarbonization, as well as in efficiency and cost savings, you’ve helped existing customers achieve.

Mitigating the effects of climate change is everyone’s job, and companies everywhere can help by reducing the GHG emissions they are responsible for. Machinery manufacturers have an especially large role to play in the effort. By improving the efficiency of the equipment they supply, these manufacturers can reduce 13 Gt, or 37%, of global emissions—and they can do so today. By perfecting existing technologies and developing new ones, they can help reduce another 17 Gt, or 49%, of the world’s total. Aside from the importance of reducing these emissions and fighting climate change, this effort will open valuable opportunities for machinery makers to capture new sources of growth—a market worth approximately €10 trillion.

Even given the considerable economic incentives, however, machinery manufacturers can’t do it alone. Their industrial customers must be willing to make the investments in new technologies. Governments, too, must be ready to support, and sometimes subsidize, the effort. But the path to success is clear, and the time to start on the journey is now.

This report was written in conjunction with the Verband Deutscher Maschinen und Anlagenbau (VDMA), Germany’s mechanical engineering industry association. The authors would like to thank the many member companies of the VDMA that contributed their expertise and suggestions.

For a German version of this report, please click

here

.