Modern factories have enjoyed a long period of continuous improvement and become models of quality and efficiency thanks in large part to lean processes and practices. At the same time, the surrounding support functions, both those close to the factory floor (such as planning and scheduling, logistics, quality control, and maintenance) and those more removed (such as finance, human resources, legal, procurement, and product development,) interact with the manufacturing workforce in much the same way they did a few decades ago.

Lean is very useful in honing standardized processes toward specific goals, such as reduced waste, but it is less effective with functions that require flexibility and continuous adaptation to changing circumstances and conditions. Costs for these support functions represent 25% to 40% of total factory expenses, a share that has grown by about a quarter in the past 20 years as direct costs have decreased.

Manufacturers can reduce these costs and increase the value of the support functions by leveraging agile ways of working. In addition to the cuts in manufacturing-related expense, we have seen companies create improvements of as much as 30% in product modification lead time and 40% to 50% in production ramp-up time. Improvements of 50% in quality resolution lead time are also achievable.

Where Agile Adds Value in Production and Support

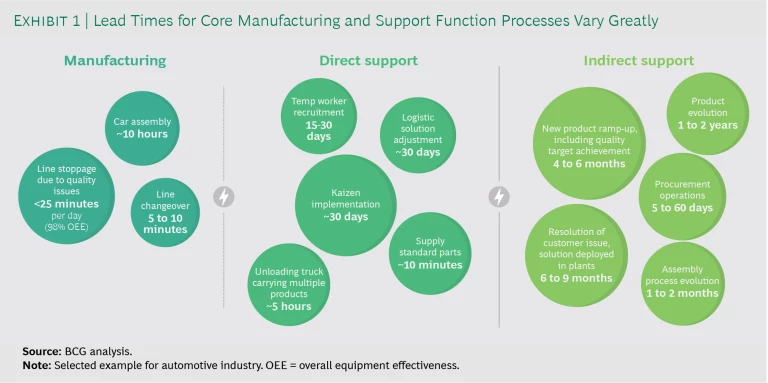

In most manufacturing processes, costly lead times have multiple causes. For one thing, the lead times for support function and core manufacturing processes vary greatly. (See Exhibit 1.) Another issue is siloed functions, which tend to slow down handoffs between functions and lead to disruptions. A common example is lack of communication between quality and engineering, which increases the lead time needed to solve customer complaints.

Fragmented efforts slow things down. When people are forced to direct their attention in multiple directions, tasks can pile up, leading to long wait times and process quality issues. Functions also often neglect to consider their internal customers. Increased lead times can occur when, for example, supply chain planning moves ahead with an ambitious schedule with little consideration of the production constraints involved.

A rigid adherence to process in the face of changing production needs can cause unnecessary delays. For example, holding fast to a weekslong process for hiring temporary workers leaves a company unable to respond to a production surge forecasted for the following week.

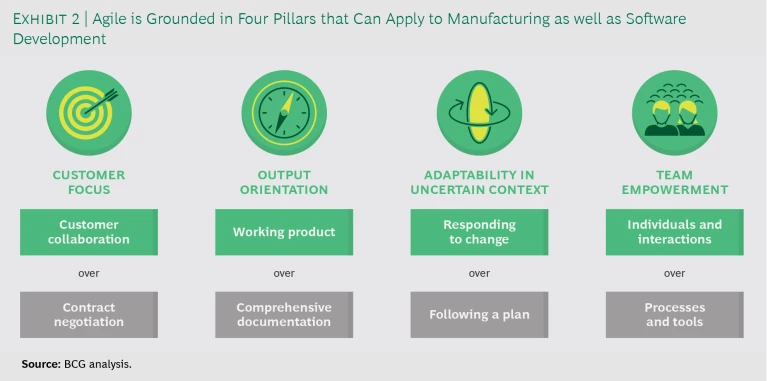

Agile can help address all of these issues. It is grounded in four pillars: customer focus, output orientation, adaptability, and team empowerment. (See Exhibit 2.)

- Customer focus means being flexible and working with customers on issues that come up rather than to trying to negotiate every detail with them ahead of time. Within the processes of resolving customer complaints, the internal handovers among various departments or functions are taken over by cross-functional teams empowered to collaborate and fix customer problems faster.

- Output orientation puts the emphasis on developing a working product rather than on the documentation that supports it.

- Adaptability helps to address unforeseen issues as new production ramps up. Instead of following a rigid plan, foremen and shop-floor teams can adjust the work plan and change machines and processes. They work with quality-control staff to ensure on-time production at the best possible quality while improving the preliminary process laid out by the prototyping teams.

- Team empowerment means that teams have the authority to determine how to achieve the goal they have been given and they decide which processes and tools they want to employ. Critical to this empowerment is that teams have all the cross-functional capabilities they need achieve results at the right level.

For a factory, agile ways of working are organized around two types of teams and apply both to production and support functions. Agile production units are based on lean management’s autonomous production units. Each agile production unit includes manufacturing and direct support functions, such as planning and scheduling, quality control, and logistics. The remaining support functions, such as customer service, quality assurance, compliance, and sourcing, are organized into groups (often called tribes) that serve inside agile support teams and provide indirect support working in a new integrated operating model. Tribes are empowered to work closely with the agile production units on common objectives.

The agile operating model addresses the causes of lead time issues described above. It breaks down the silos separating production and other functions. Teams made up of people with the required expertise are empowered to solve complex issues at the operational level, rather than putting out fires as production problems occur. Site management and support function experts intervene only when necessary. Agile production units prioritize work with one goal in mind: achieving the production objective within performance targets.

The agile factory will see increased performance in time, cost, and quality when dealing with unusual situations and problems.

The agile factory won’t necessarily increase productivity per unit, but it will perform at a higher level in terms of time, cost, and quality when dealing with unusual situations and problems. It will go beyond physical production to add value in such support areas as product design, customer service, quality, and compliance.

Putting Agile to Work

Consider how an agile approach changes three common manufacturing scenarios that are prone to lengthy and costly lead times and in which the interplay between production and support functions plays a crucial role. Agile brings value to these cases by enabling production and support functions to better empower and develop teams, solve issues requiring customized solutions quickly, and deliver concrete results faster.

New Product Introduction. Today companies develop and prototype new products outside of the factory in a sequential process involving innovation, marketing, and product development teams. Prototypes are also often developed jointly with suppliers chosen for a particular product series. Marketing and sales assess the prototype, and management determines a schedule for launch.

Under this process, the product is fully developed and schedules have been set for sales and marketing campaigns before production teams get involved. As a result, major reworks are often required, including changes to the engineering, assembly, or specifications of entire component parts. In many situations, the first batches are manufactured at huge unit costs, because the factory must put on extra shifts and pay more for rush transportation to meet the predetermined timeline. In some situations, the launch date is threatened or delayed.

In an agile process, cross-functional teams are responsible for new product development and delivery to market. Production experts ensure ready manufacturability using the current production lines and supply chain. The teams are responsible for ensuring that regular suppliers are able to produce the components at the right pace and quality level; in some cases suppliers could be tapped to co-develop certain components. Operational feedback from the agile production units to the project team helps enhance the manufacturability and quality of the final product. The first viable product is followed by additional, improved releases.

Customer Complaints or Recalls. Currently for most companies, the customer service department in a particular region or market registers complaints or recalls, which are batched together at headquarters and sent to quality control. A series of investigations ensues: by quality control, supply chain, procurement, and finally production. The process is fragmented among every function in the manufacturing organization, and it often takes months to find the root causes of the problem. Worse, there is no overall ownership of the necessary corrective actions, because each function has its own priorities and sets its own schedule for implementation.

In contrast, leadership in an agile manufacturing organization sets a clear objective to reduce recalls and complaints by a particular percentage. Agile production units are assigned responsibility for each major product or product family. The team includes sales reps for the major markets who know the customers and the market environment, as well as experts in quality, procurement, supply chain, and production. The team proceeds systematically by categorizing the major recalls and complaints and prioritizing the issues to be analyzed and corrected. Beginning with the most important issues first, the root causes of the problems are addressed and eliminated. Results should be seen in a matter of months.

Change Requests to Standard Products. In large-scale manufacturing industries, such as aviation, defense, or shipbuilding, most customer orders are made outside of the catalogue. Customers choose a type of product then specify a series of modifications to meet their needs. During the production process, the customer inspects the order from time to time and issues change requests to address problems or evolving requirements. Implementation of the changes takes time, and the process to review, approve, and dispatch them is long and complex. Delays, missed deadlines, and penalties are common.

If the process is organized in an agile way, the agile production unit is given the objective of pushing the product through the process and gaining customer approval as quickly as possible. The contract manager and product manager roles are played by same person. The team has all necessary technical expertise, including production know-how from the factory floor. Every batch of change requests from a customer visit or inspection is prioritized and dealt with in an agile way, with the objective of addressing the change requests without slowing or stopping production.

The Steps to Building an Agile Factory

Since the agile process is new to manufacturing, we recommend that companies start small, with a pilot or two, and let employees become comfortable with the concept of agile and working in new types of teams toward common objectives. Support function personnel in particular need to adapt from working toward process-oriented goals to achieving customer- and quality-focused objectives. There are three steps.

Since agile is new to manufacturing, companies should start small so employees can adjust to working in new types of teams toward common objectives.

1. Choose where to start. This can involve creating agile production units with manufacturing and direct-support personnel or transforming the ways that support functions work with production in order to address a key strategic objective. Companies with mature lean processes may find the agile production units option simpler since it builds on exiting autonomous production units. The second path is preferable in situations that require intense and quick multifunctional cooperation, such as a new product launch, a battle for pole position in a major market, or a ramp up of quality.

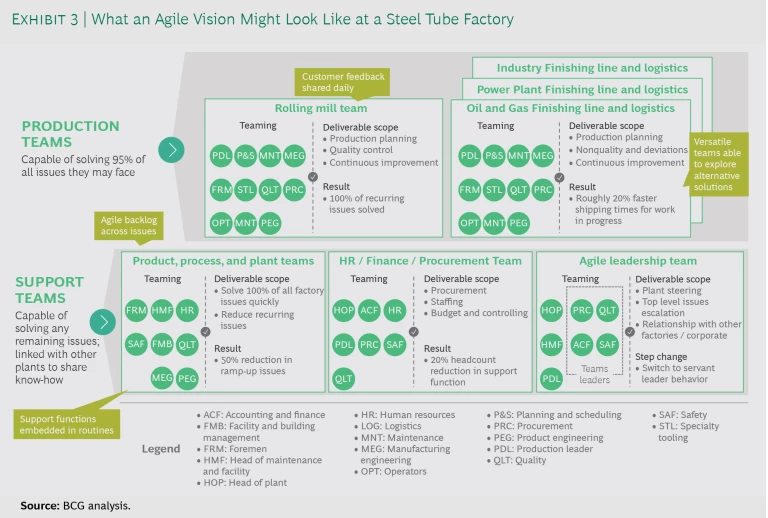

2. Define the main business objective (“the what”) and the target vision (“the how”). The objective should be bold so employees can’t succeed without thinking out of the box. Examples include cutting extra production hours in half or reducing end-of-line nonconformities to zero. For support functions, the objective could be reducing the time it takes to resolve customer complaints. It should also serve to unite agile teams towards one goal.

At the same time the target vision should help employees understand what agile should look like. It should include such considerations as how customer feedback is shared, how the agile backlog across issues is addressed, how teams explore alternative solutions, and how support functions are embedded in routines. (See Exhibit 3.)

3. Reorganize on the basis of the target vision using agile methodology. Define the skills and expertise needed to tackle the problem. Identify the leaders responsible for the multifunctional teams charged with reaching the objective for their area. For example, in the customer complaint case listed above, there could be a leader for complaints on Product A and one on Product B. Put the teams to work and ensure that there are frequent opportunities for escalation. Don’t put in place any type of processes or procedures. The teams should feel invested with the objective and empowered to make the company better in that area.

Agile may not suit every manufacturing company or situation. But adapting the agile principles of cross-functionality, collaboration, customer focus, and adaptability can alleviate major pain points in the production process and facilitate improved cooperation between production and support functions. The potential rewards in reduced costs and higher customer and employee satisfaction are well worth exploring.