To reclaim a strategic advantage in this critical area, the US must do more than increase its share of global manufacturing.

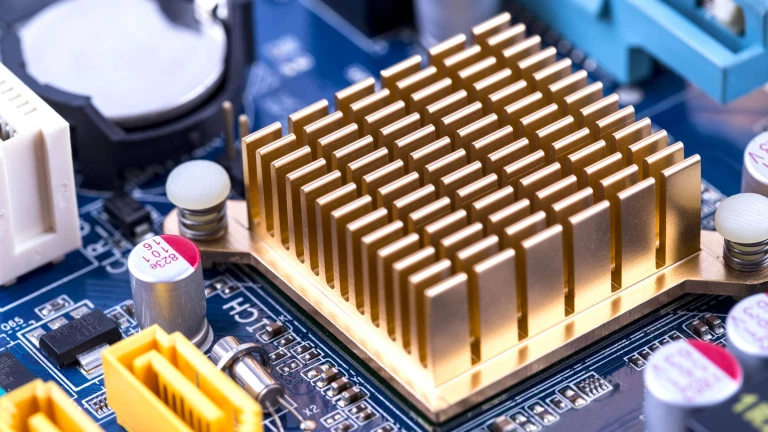

Advanced logic technology is critical for the national security and economic progress of any developed economy. As a result, advanced logic technology has been at the center of recent discussions around the globe--in the US, EU, Japan, Taiwan, South Korea, and elsewhere.

Access to leading nodes (which today correspond to the technology nodes of less than 10nm) is critical to produce the most advanced logic chips. Until 2018, the US led the world in advanced logic technology needed to develop leading nodes. Today, while still a global leader in semiconductor sales and value-add overall, the US depends heavily on East Asia for the manufacturing portion of the value chain. And this dependence is particularly significant for leading-node manufacturing, where 90% of the total global capacity is currently concentrated in Taiwan.

The recent push to attract global semiconductor manufacturing leaders to invest in building fabs in the US does address one key issue: it reduces the risk of supply disruptions for critical applications. But if the US wants to reclaim strategic advantage, it will need to go beyond increasing its share of manufacturing and reestablish its leadership in advanced logic technology.

The next few years present an opportunity to reestablish this leadership. Among other things, the industry will face a major transition to new leading nodes, expected to be introduced starting in 2024–2025, that still require significant R&D to turn them from scientific developments into viable manufacturing processes. In addition, much new capacity must be built all over the world to meet expected growth in chip demand. Based on current industry analyst forecasts, we estimate that the industry may need more than 45 leading-node fabs—each with capacity of 35,000 wafers per month (wpm)—by 2030.

Reestablishing US technology leadership in advanced logic technology through greater R&D investment is also critical and involves three essential, interrelated elements:

- Regaining manufacturing process technology leadership with IP and know-how based in the US to enable new leading nodes

- Aggressively building US-based leading-node fab capacity—enough fabs for the US to sustain the ongoing investments needed to maintain technology leadership

- Developing complementary advanced packaging capabilities, which are increasingly needed to make the most powerful logic devices, with state-of-the-art facilities in the US

These three essential elements to achieve technology leadership depend on a dozen enabling factors which we discuss in detail in an upcoming report.

Among these factors, the two most critical gaps are in the areas of fab costs—over ten years, it is about 30% more costly to build and operate fabs in the US relative to other countries with leading-node manufacturing, primarily owing to government incentives available elsewhere—and in public funding for R&D related to semiconductor manufacturing in the US, which, when adjusted for factor costs (such as labor rates), lags that in Taiwan and South Korea.

This strategic challenge will require substantial commitment and investment from the private sector over multiple years, supported by comprehensive US public policy and funding.

This work is the result of an independent study commissioned by Intel. BCG is wholly responsible for the analysis and conclusions that appear in this report.