Higher levels of automation and flexibility help manufacturers offset labor shortages while boosting service and safety.

Advanced logistics systems are ready for deployment in factory operations. Better and cheaper automation is now available to move items to, from, and within plants and warehouses.

E-commerce players have been frontrunners in deploying advanced automation in logistics to address labor shortages and improve productivity, increase flexibility, and accelerate cost reduction. We expect that leading manufacturers will follow their example to unlock value and boost competitiveness.

The automated systems that enable advanced logistics are flexible, scalable, and easy to install. They are powered by a combination of sensors, software, computing, and high-speed connectivity. We see a wide array of applications for factory operations. Companies can use robots for handling and picking, autonomous mobile robots (AMRs) or drones for material transport. They can utilize equipment with computer vision for inventory management and use software to support planning, control, and execution.

The business case for investing in advanced logistics is stronger than ever. By implementing these systems, manufacturers can reduce in-plant logistics and warehousing costs by approximately 30%. To capture these benefits, companies need to select applications based on a rigorous assessment of economics and implement the right organizational and technological enablers.

What Makes Advanced Logistics Transformative?

Advanced logistics systems are part of the automation revolution in manufacturing. Technological advances, such as machine learning, cloud computing, and vision systems, are making it possible to fully automate many existing processes that have traditionally been manual or semiautomated. These innovations allow for significantly broader applications of advanced logistics, including high-value use cases. At the same time, automated systems are becoming less expensive and easier to integrate.

Investing in automation has become more attractive because labor shortages around the world are driving wage levels higher. Advanced logistics will help to ease the impact of labor shortages and boost productivity by automating many jobs that primarily involve routine manual activities. Collaboration between humans and machines will become more common, creating opportunities for future-oriented jobs that require new skill sets.

The transformative potential of advanced logistics arises from the combination of multiple features:

- Machine Intelligence. Major improvements in natural-language processing, computer vision, and sensors enable greater autonomy for devices while enhancing precision, such as for handling systems. Advanced sensor technologies generate vast amounts of data that can be used to monitor the state of devices, product-related data (such as location, using visual recognition or RFID tags), and ambient parameters (such as temperature and humidity). Automated equipment uses the improved technology to autonomously perform more-complicated tasks. This includes complex handling activities covering a multitude of different part sizes and geometries, from large parts to bulk material.

- Plug and Play. In a plug-and-play approach, advanced logistics systems are quickly set up and integrated into existing factory systems, such as for manufacturing execution, warehouse management, and enterprise resource planning. This is made possible by new service-oriented architectures, better connectivity via the Internet of Things (IoT), holistic data models, self-learning, and interface and programming improvements. The integration enhances a logistics system’s ability to anticipate product geometries, routes, or picking sequences.

- Adaptability. Advances in data-processing technologies and access to cloud services enable logistics systems to learn and autonomously adapt to complex, changing environments. Systems can use machine learning and computer-vision technologies to guide themselves through complex environments. AMRs, for example, can automatically change routes, in contrast to traditional conveyor belts for which the setup requires long-term planning and cannot be quickly adjusted to new demands. It is also possible to use AMR fleets across different sites. Further, optimization algorithms powered by artificial intelligence (AI) improve inventory location assignments and accelerate reaction to demand peaks. Adaptability to the physical constraints of storing different-sized items is also possible with new flexible storage systems and smart shelves. These advantages mean that autonomous systems require lower capex investments in infrastructure.

- Mobility. Battery powering enhances the mobility and autonomy of in-plant logistics systems. Improvements to battery technology have increased uptime and accelerated recharging compared with batteries that were available a few years ago.

This combination of features yields multiple benefits:

- Productivity. A high degree of automation reduces the need for manual labor. It also increases the utilization of transport systems, storage solutions, and other assets. The ability to reduce inventory levels and work in progress optimizes working capital.

- Quality. Better functioning transport systems reduce incidents of damaged parts and mistakes, such as picking the wrong item from shelves. Advanced systems also promote higher rates of on-time delivery of parts.

- Safety. AMRs can replace conventional equipment, such as forklifts, that are dangerous or physically demanding for human workers to operate. Advanced equipment can also perform tasks in hazardous environments or operations that could lead to repetitive-stress injuries.

What Are the Industrial Applications?

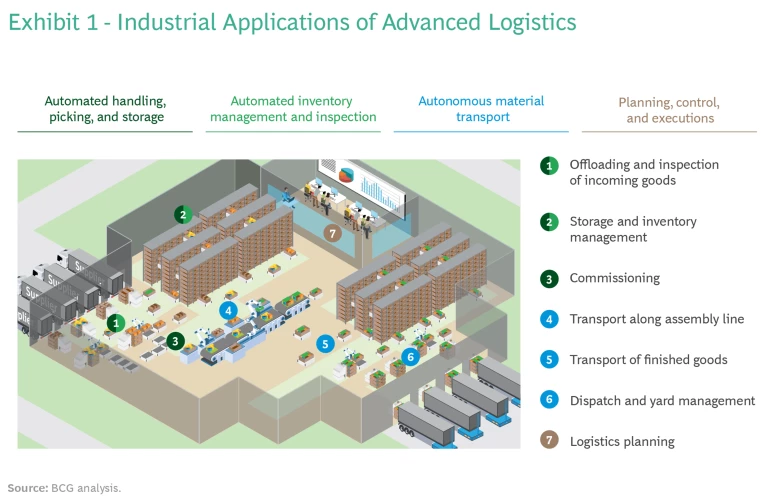

Advanced logistics technologies create value through a large variety of use cases across the entire value chain of factory operations. (See Exhibit 1.)

There are four major categories of applications:

- Automated handling, picking, and storage

- Automated inventory management and inspection

- Autonomous material transport

- Planning, control, and execution

We examine each in turn.

AUTOMATED HANDLING, PICKING, AND STORAGE

Initializing and programming conventional robotic devices to identify and safely handle materials stored in standardized boxes entails tremendous effort. In contrast, advanced robotic devices with AI-based computer vision systems can autonomously detect, move, and pick materials for transport or storage. They can identify objects and calculate the optimum gripping point for safe handling and movement.

High-density three-dimensional storage systems (with parts stored on racks rather than the floor) can reduce warehouse space requirements by up to 70% and improve labor productivity by a factor of ten. Advanced vision technologies, in combination with machine learning, allow devices to perform highly complex picking or depalletizing, with systems reaching 700 to 1,000 tasks per hour. These systems are highly reliable, with uptimes reaching 99.5% enabled by self-diagnosis and self-reporting of issues by robots. Companies can use this functionality to easily customize and adjust systems to meet demand, including by increasing capacity during continuous operations.

AUTOMATED INVENTORY MANAGEMENT AND INSPECTION

Conventional solutions for tracking material rely on standard location identifiers (such as RFID for the highest-value parts) or material counting systems (such as weight control for the lowest-value parts). These systems have important limitations. They only track material in fixed locations, such as an RFID gate or weighing station, and provide no visibility of parts in other locations or while in transit. And they are not useful for all materials for economic reasons (such as cost of implementation) or technological reasons (such as material size or bulk state).

To overcome these limitations, innovative logistics solutions use advanced computer vision systems with AI-based image recognition to identify and count parts as well as pinpoint their locations in the warehouse and production process. Additionally, these systems can support incoming goods inspections by verifying the correct material and quantity. Inspectors can focus their work on components with abnormalities identified by the system. As another benefit, advanced systems can automatically place frequently used products near workstations while storing the least-used products further away. Select online and grocery retailers were among the first companies to successfully apply computer vision systems for shelf monitoring and tracking of inventory and the movement of goods. Leading manufacturers are already using these systems to, for example, manage raw material inventory.

AUTONOMOUS MATERIAL TRANSPORT

Companies have been using conventional automated guided vehicles (AGVs) to transport items for years. These vehicles follow a preset path loaded onto an internal computer and need guidance from a supporting system, such as magnets on the floor or sensors in the path periphery. As a result, they cannot autonomously react to changes in the factory layout or be installed using a plug-and-play approach.

In recent years, AMRs with significantly more autonomy have become available to make point-to-point deliveries and lead tugger trains. These advanced systems generate virtual maps of their surroundings without any supporting infrastructure. Improved sensing, planning, and action capabilities enable AMRs to autonomously detect objects, disturbances, or obstacles and adjust speed and direction.

A cloud platform is responsible for the higher-level control, planning, and actions of AMRs and their execution subsystems as well as integrating the vehicles with other systems, such as production planning. Plug-and-play functionality is enabled by VDA 5050, a standardized communication interface. This functionality allows companies to seamlessly integrate AMRs from many different manufacturers and temporarily combine several subsystems into a superior system (for example, a tugger train comprising AMRs from different manufacturers). After the initial setup, AMRs use machine learning to quickly adapt to changing environments, which facilitates deployment at scale.

Manufacturers can manage a fleet of up to 600 AMRs that combines a wide array of specifications—such as payloads ranging from 50 to 1,500 kilograms. These vehicles travel at 1.0 to 1.8 meters per second when loaded, enabling them to perform more types of transport tasks. The use of AMRs can reduce a human operator’s daily walking distance by more than 15 kilometers. Beyond boosting productivity, these benefits significantly improve the workplace environment by reducing operator fatigue and the risk of workplace accidents and injuries.

A manufacturer can further decrease system complexity and costs by placing trackers on critical objects or workers. The trackers communicate their positions to AMRs so that they can avoid collisions without needing to sense the exact location of objects or humans. For example, “robotic tech vests” use built-in sensors to alert robotic systems to a warehouse worker’s presence.

Leading companies are already capturing the advantages. A German automotive manufacturer, for example, recently replaced its traditional assembly line with a driverless transport system comprising more than 400 AMRs. The greater flexibility enabled by using autonomous vehicles, rather than reconfiguring the assembly line, facilitates changing production processes or technology and integrating new products. It also allows the manufacturer to rapidly switch from continuous flow production to discontinuous assembly operations.

Manufacturers should keep in mind that some industrial setups are better suited to AGVs or other conventional solutions rather than to AMRs. The higher investments required for using AMRs are not justified for standardized transport processes that require limited or no flexibility. In addition, AMRs’ autonomous routing and unplanned stopping are not suitable in production environments that prioritize stable throughput times.

PLANNING, CONTROL, AND EXECUTION

Most large companies operate a logistics control tower. Its tasks traditionally relate to the central planning of logistics activities (such as order prioritization and planning of personnel and asset capacity) and the subsequent monitoring of performance against targets. The control tower staff devotes significant effort to capture data for the calculation of KPIs, which entails a time lag that often delays corrective action.

Major advances in IoT technology now enable ad-hoc decision making in nearly real time and automated execution. Sensors on equipment generate a vast amount of data that is processed immediately on “edge” devices close to the sensor, thereby eliminating the latency created by processing in the cloud. The processed data is then sent to the cloud using advanced data transmission standards such as 5G or WiFi6, which can rapidly transfer large data volumes. In the cloud, enhanced computing power and advanced algorithms run optimization models.

With these advances, the activities of the control tower shift from humans making decisions centrally to algorithms running on decentralized devices. For example, picking sequences for AMR routes are calculated by algorithms rather than being determined by people.

Importantly, staff in the control tower remain in the loop to address exceptional cases that algorithms cannot handle. Greater levels of automation enable staff members to work with significantly higher data volumes. As a result, the control tower’s visibility extends upstream to suppliers and downstream to distribution centers. Staff members gain full visibility over the supply chain while being able to focus their attention on specific issues.

Getting Started

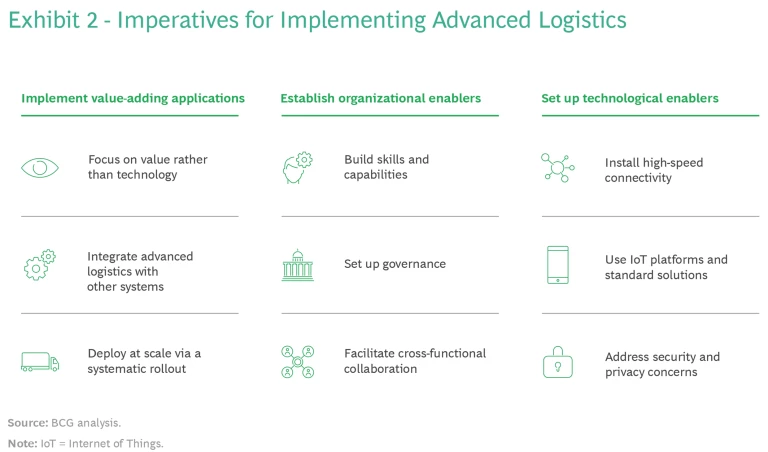

Industrial companies need to make design choices among this wide array of applications that promote their priorities and strategy. To successfully deploy advanced logistics and quickly benefit from new technologies, they should follow a six-step approach—taking steps three through six simultaneously. Within these steps, we see several imperatives for successful implementation. (See Exhibit 2.)

1. Assess the current state. Accurately assessing your current state is a prerequisite to earning a quick return on investments in advanced logistics. The assessment typically identifies significant pain points and value pockets to prioritize for implementing new technologies, often in combination with expanding applications of traditional lean manufacturing. It also provides a perspective on your organization’s capability to transform and the timeline for making it happen.

2. Define the target picture and roadmap. Apply the assessment to define a target picture for future applications and the technological and organizational enablers. Use technology solutions to reimagine processes, rather than simply replicate existing processes with technology added. Value creation should be the sole basis for selecting technologies. The value may extend beyond pure productivity to include operational resilience and sustainability.

Next, define a roadmap that sets out the individual steps to achieve the target picture and defines how applications will be scaled up from pilot areas to the full network. The roadmap should take into consideration organizational capabilities, such as digital and operations skills, as well as the financial resources available.

The target picture and roadmap must be based on a solid business case to ensure that resources are allocated to achieve the best return on investment. The economics of implementing advanced automation should be compared with that of efficient manual and semi-automated states. One thing to bear in mind, however, is that in some cases advanced solutions are not preferable from a process or financial perspective. It is also valuable to run sensitivity analyses to evaluate how changing the products being manufactured would affect the economics of advanced automation. In addition, the business case should account for the availability of numerous financing and leasing options to minimize the impact on liquidity.

Define the future-state logistics processes as soon as the target picture and roadmap are completed. This new process design should entail not only the physical material flow but also the information and data flow.

3. Build capabilities and set up governance. Build knowledge throughout the organization about the opportunities, limitations, and risks involved in implementing various advanced logistics systems. To manage these systems, employees need to apply both functional and soft skills. Many employees will need training in installation, programming, operations, and maintenance, as well as guidance on how to tailor standardized solutions to specific tasks. Whether through training, new hires, or the use of external experts, acquire knowledge on how to best integrate advanced logistics into operations. Successful integration requires the ability to think creatively about how advanced logistics systems can perform diverse tasks. Firmly anchor the entire capability-building program, including continuous enhancement of the workforce, within the organization. Establish strong governance across departments and stakeholder groups and facilitate cross-function collaboration.

4. Set up the technological backbone. In our experience, it pays off to focus on establishing the right technological backbone during the design phase of the project. To feed the analytics that lie at the core of advanced logistics, implement an integrated data platform that captures, stores, and processes data from all involved systems and devices. (See sidebar, “Implement a Modern System Architecture.”) Connect all logistics systems and devices to the integrated platform—preferably through high-speed wireless technology to ensure flexibility. It is often possible to do this by upgrading existing assets with additional sensors or a new controller. Replace any devices that cannot be connected to the platform. In addition, address security and privacy concerns—such as by utilizing secure wireless connections that use the VDA 5050 communication interface and the TLS cryptographic protocol.

Implement a Modern System Architecture

Implement a Modern System Architecture

- High coverage of sensors and edge devices to capture and pre-process data. Plug-and-play systems are available for new installations or to upgrade existing hardware.

- Strong connectivity of the sensors and edge devices to the cloud. Wireless connectivity through 5G or WiFi6 improves reliability and stability, which makes it possible to set up a flexible layout and easily connect devices in hard-to-reach areas.

- A cloud-based IoT platform to connect a multitude of different data sources, such as physical sensors and IT systems. The platform allows bi-directional data flows between data sources and applications while maintaining privacy and security. To effectively operate the platform, the setup needs standardized and harmonized data formats and interfaces (for example, VDA 5050 for AMRs). Cloud-based platforms are widely available today as a service, making them easily scalable without the need for hardware investment.

- Software applications to process data from different sources and generate value through transparency, predictions, and autonomous system control. Companies can tailor these applications to their needs or choose among many off-the-shelf solutions for orchestrating logistics within the factory.

5. Select technology and implementation partners. Most companies will need to collaborate with external partners to implement advanced logistics solutions. These partners include providers of automation hardware, analytics providers, and potentially third- or fourth-party logistics providers. Involve them early in the implementation process and agree on the future operating model, interfaces, and data to be shared. Especially when working with startups as providers of systems, begin with a small-scale pilot to test logistics solutions before scaling them up throughout the plant.

6. Track results and optimize continuously. The ramp-up phase for calibrating and implementing new systems often takes several weeks. However, comprehensive preparation, jointly with the technology partner, can significantly reduce the time required and the risk of failure. After ramping up, continuously track system performance and improve operating parameters to achieve the highest performance level. This requires defining a set of performance KPIs and implementing a continuous improvement process within the organization.

By providing higher levels of automation and flexibility, advanced logistics solutions can help manufacturers address labor shortages and boost service and safety levels, among other benefits. Achieving a rapid and high return on investment requires focusing on how technology can relieve pain points and create business value. Manufacturers that successfully tap into the transformative power of advanced logistics will reap the rewards throughout their factory and warehouse operations.