Why hasn’t artificial intelligence fully transformed supply chains ? Several years ago, some of us predicted that AI-powered automation would lead to “ the death of supply chain management. ” We saw the potential to turn supply chains into self-regulating utilities that optimally manage end-to-end workflows with little human intervention. However, despite heavy investments, companies have not realized the vision of AI-managed supply chains.

A recent study by BCG and Aera Technology sought to pinpoint the source of companies’ struggles to maximize value from AI in supply chains. We found that the root cause lies not with technology but with how and where companies are applying it. Most still focus on using AI for analytics and prediction—for example, to forecast demand and plan production. Companies have not pursued the more valuable application of using AI to make recurring decisions by recognizing patterns in big data that humans cannot see.

To unlock the full potential, companies need to deploy an AI-powered learning system that is integrated across functions. This system makes decisions based on enterprise-wide and external data and continuously learns from the outcomes to improve performance. Analytical engines automate decision making instead of just providing insights to practitioners, who must retain the burden of making decisions. Success requires fostering people’s trust in AI and introducing a new operating model, among other enablers. Companies that make the right investments will increase their resilience to market volatility and talent scarcity and achieve higher sustained performance.

Fundamental Problems Persist

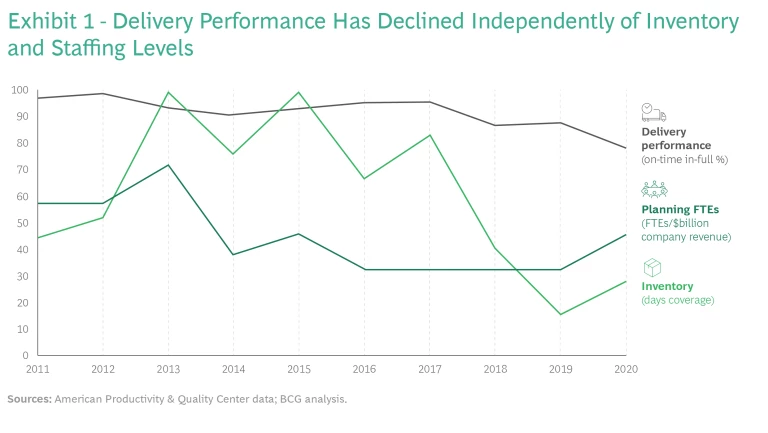

BCG’s analysis of supply chain KPIs from 2011 through 2020 reveals insufficient progress in addressing fundamental supply chain problems. (See Exhibit 1.) During that period, delivery performance declined independently of inventory and staffing levels. Even when companies boosted inventory and staffing levels at the onset of COVID-19, they still could not prevent a steep decline in service.

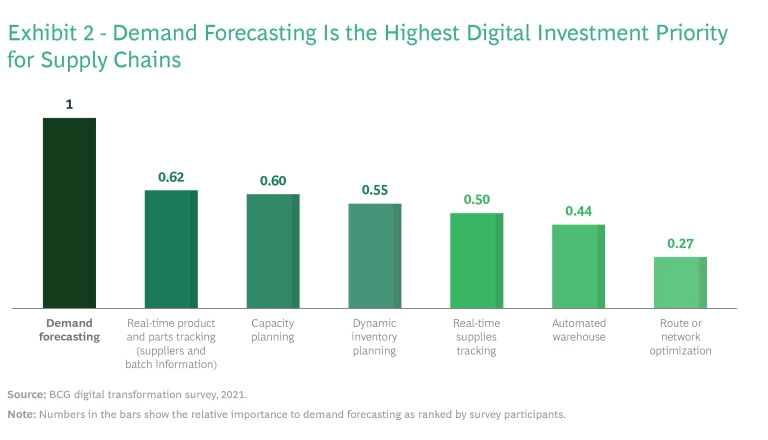

To improve supply chain performance, many companies have ramped up their investments in digital technology. A BCG survey found that companies plan to use this spending mainly to enhance traditional subfunctions. Demand forecasting is the highest priority, followed by tracking, planning, and automation. (See Exhibit 2.) We see little evidence that companies are considering AI use cases that enable autonomous decision making. In the absence of entirely new applications of AI, it is not surprising that the decades-old challenges of declining service levels, suboptimal inventories, and excessive manual effort persist.

Why Have Companies Struggled?

Companies have struggled to use AI to address fundamental supply chain challenges for a variety of reasons. Supply chain management is inherently complex. It requires the participation of several functions (including procurement, manufacturing, logistics, and sales) as well as subfunctions (such as demand planning, inventory planning, and scheduling). Organizational structures and incentive systems motivate employees to optimize the performance of their own function or subfunction rather than that of the end-to-end supply chain. Managing tradeoffs among stakeholders is tricky because supply chain personnel often need to address competing requirements from other functions without having the power to make the ultimate decision.

Companies often try to improve their supply chain performance by adding more people to a function (as shown in Exhibit 1). But the problem is typically a lack of subject matter knowledge, which cannot be solved simply by creating larger teams. High-potential performers often do not regard supply chain management as a preferred long-term career path and move to other functions after only two or three years. Because of the high turnover, institutional knowledge ends up dispersed across the enterprise or escapes the company altogether.

These organizational challenges make it hard for supply chain managers to focus on solving problems that can improve long-term performance, such as building new skills, forming the right partnerships, and setting the right KPIs.

Companies have not pursued the more valuable application of using AI to make recurring decisions by recognizing patterns in big data that humans cannot see.

On the technical side, we have yet to see proven at-scale solutions for AI-driven learning systems in supply chains. Questions remain about whether it is possible to deploy an all-encompassing integrated system to address all supply chain decisions. Obtaining good-quality data to train learning systems is also a challenge, despite the explosion in the availability of data and the development of innovative technology to integrate it. Moreover, companies are already investing significant funding and resources in new planning systems to address pandemic-induced issues, so they may not be able to devote money and personnel to implement learning systems in the near term.

At many companies, efforts to deploy new technology to improve supply chain performance are impeded by misconceptions. For example, companies place too much faith in consensus decision making to promote alignment and commitment among stakeholders. They are also too confident about people’s ability to make sense of events, situations, and data. Finally, they over-rely on linear upgrades of technology, failing to recognize the need to deploy disruptive technology and adapt legacy systems when doing so.

The New Vision: An Integrated Learning System

To fulfill the promise of an AI-powered autonomous supply chain, companies need to deploy cognitive automation at scale in an integrated learning system.

Here is an example that illustrates what this means in practice: An AI-powered platform learns from supply chain practitioners’ past decisions by considering how they affected key objectives (such as service level and cost to serve). Based on historical patterns, it recommends actions to respond to new, similar situations. As execution proceeds, the platform continuously analyzes real-time data to make recurring decisions that optimize performance. The platform conceals complexity from the company’s personnel and engages with them only as needed. In the earliest stages of using the platform, practitioners are involved in reviewing the validity of proposed actions and executing them. They also give feedback to data scientists and system architects on how to enhance the platform. Over time, the platform matures toward more automated execution with less human intervention. By digitizing the supply chain function’s institutional knowledge and autonomously executing decisions in collaboration with humans, the platform helps to address the challenges of talent scarcity and high turnover.

To unlock the full potential, companies need to deploy an AI-powered learning system that is integrated across functions.

A leading consumer goods company is using such a platform to unlock new levels of agility and learning. A key application is accelerating decision making, execution, and learning when introducing new products into a market. For instance, the platform has rapidly identified which legacy products to remove from the market to maximize the economic benefits of new products. The company has used the capabilities to support a wide variety of applications—such as optimizing media buys based on product availability or stopping a purchase order if a vendor faces sustainability challenges. So far, the platform has issued 300,000 automated recommendations, approximately 60% of which were executed without human intervention. The company now aims to increase this to more than 90%. Reaching this stage has not been easy. The company needed to invest significant effort to design the platform, as well as to build people’s trust in AI-generated recommendations and automated execution.

How Can Companies Realize the Vision?

Companies must take several steps to realize the vision of an integrated learning system.

Focus on cross-functional decision making amid uncertainty. Prioritize AI use cases that apply across several functions, rather than seeking to improve the performance of specific, functional planning activities. Look for cross-functional, transactional applications for which AI can recommend decisions under conditions of uncertainty by learning from comparable situations in the past.

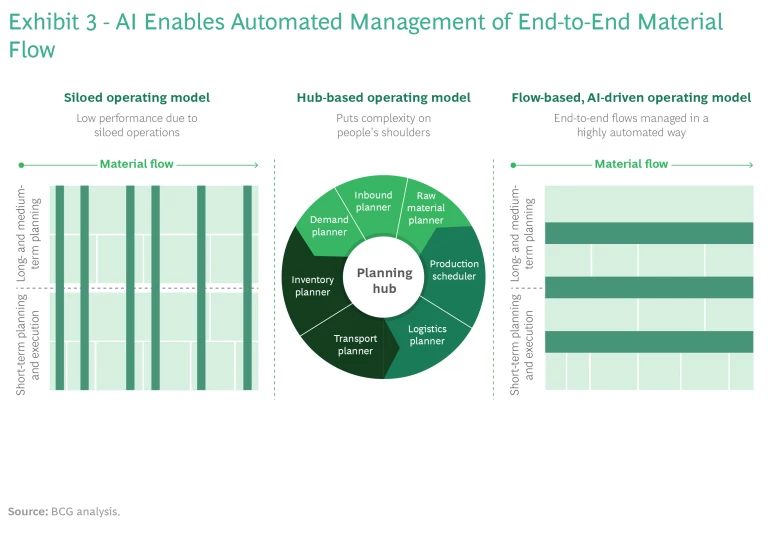

Design entirely new human–machine operating models. Today, people execute most of the work while using analytics platforms to provide often complex situational insights. In the worst cases, they do so in organizational silos that operate too independently along the end-to-end material flow. In the best cases, the company uses a cross-functional, hub-like operating model in which planning teams try to find good solutions in a complex environment with some help from analytics. In the new operating model , a carefully designed AI platform finds the solutions. (See Exhibit 3.) The vision of seamlessly connecting information across the various “flows” of activity in the end-to-end supply chain becomes more realistic. The AI engine supports planners in gathering information from all sources and escalates only critical decisions to the manager responsible for a specific flow. Practitioners make sense of the AI-generated recommendations, foster “explainable AI” concepts, and promote trust in the recommendations. System architects apply lessons learned to improve the next-generation design, thereby building the AI platform’s capability in decision making.

Double down on building people’s trust in AI. Especially in the first stages of implementation, practitioners need to collaborate with data scientists and system architects to continuously improve the AI engine’s recommendations. Practitioners will quickly realize that the AI engine will take over important aspects of their work. To ease their concerns, a company needs to embed trust building into a longer-term operating model strategy that includes new roles for traditional decision makers.

Gear pilots toward automation, not visibility and analytics. Many digital pilots are geared toward providing full visibility, often in real time. Indeed, some companies see visibility as a prerequisite for each new step in the digital supply chain journey. However, visibility puts the burdens of complexity on people by forcing them to process too many signals. Analytics create a similar problem. Planners need to understand the insights they receive, but typically they do not have enough time to digest all the inputs and make good decisions. A better approach is to use pilots to test the application of automation to generate decisions. Practitioners, data scientists, and system architects can gain valuable experience in collaborating to improve the AI engine.

Learn from other functions and industries. Front-running industries, such as airlines and autonomous-vehicle manufacturers, are using cognitive automation at scale. Although far afield, the use of AI in autonomous vehicles provides an analogy for supply chain managers. A self-driving vehicle requires automated decision making, constantly and at scale. The AI algorithms that power it have been trained—in real life and in simulators using a wide variety of data sets—to react to unforeseen situations. For supply chain managers, this points to the need to find the right data sets (internally and externally) to train the decision engine. To make this possible, the role of the data purchasing manager will become more prominent in procurement.

Implement the foundational building blocks. Define a comprehensive, value-focused roadmap for the development of the integrated learning system. The roadmap should cover the implementation of the technical prerequisites, such as appropriate data management, data governance, and data quality capabilities. It should also detail how the learning system will be integrated with core systems for supply chain planning, multienterprise collaboration, and execution. To ensure continued momentum and funding support from leadership, the roadmap should deliver value to the enterprise across multiple time horizons.

Introduce new roles. In a self-regulating supply chain, personnel transition from management to a variety of specialized roles, with new charters and profiles. (See Exhibit 4.) The emphasis shifts from fire fighting and routine decision making to building and orchestrating a supply chain ecosystem that includes technology providers and data integrators.

The death of supply chain management is inevitable. To hasten its demise, companies must think differently about how and where they apply AI. Instead of using it to analyze data and enhance visibility, they need to trust AI’s ability to continuously learn and make decisions that optimize performance. The first companies to master the challenges will lead the way in capturing the full value of a self-regulating supply chain.