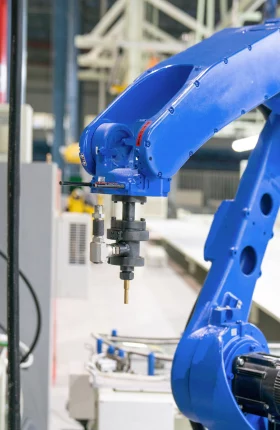

The technologies needed to overcome many longstanding barriers to shop floor automation—and the skills needed to use them in combination—are finally available.

Manufacturing is on the verge of an automation revolution. By skillfully combining innovative technologies—such as machine learning, vision systems, and high-speed connectivity—manufacturers can overcome many long-standing barriers to realizing the vision of a highly automated factory.

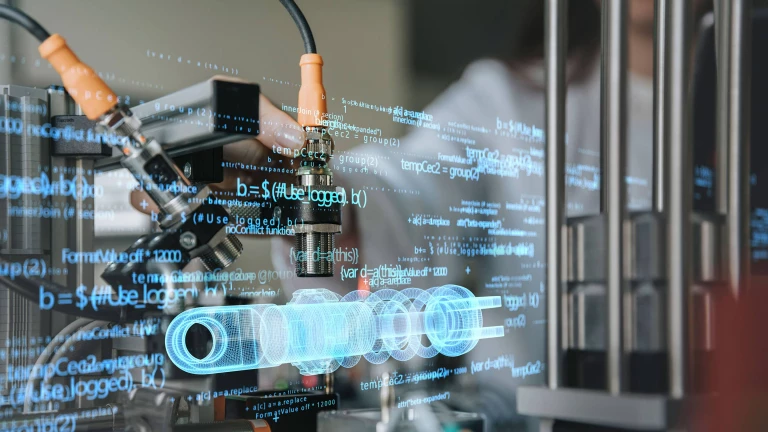

The conventional automation technology deployed in most factories has severe limitations. Robots can perform repetitive and predictable tasks, but they have trouble accomplishing more complex ones—such as handling cables or safely collaborating with humans at maximum speed. These limitations result in a gap between manufacturers’ current levels of productivity and those that have recently become technically and financially feasible. (See Exhibit 1.) A recent BCG study found that closing this “automation gap” can yield labor and quality improvements that reduce conversion costs by up to 25%.

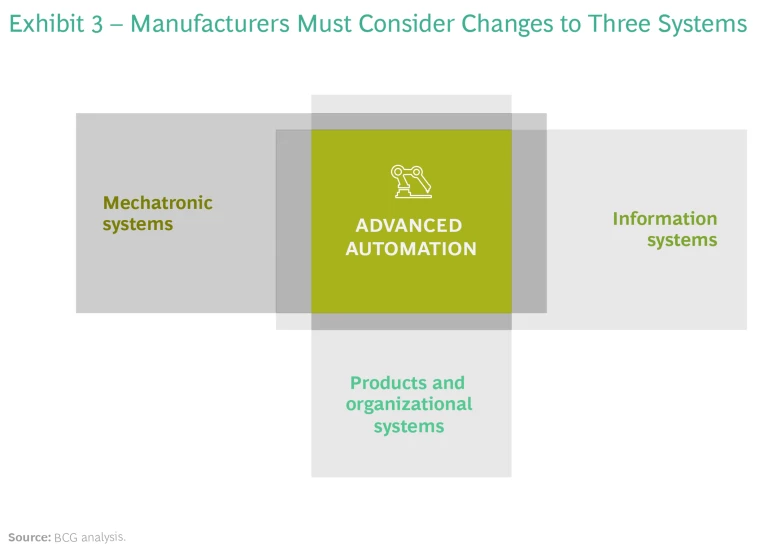

Changes to mechatronic systems, such as robots, are only one part of the solution. Manufacturers must also change their products, organization, and IT setup to enable higher levels of automation. A comprehensive approach begins with identifying and prioritizing high-value applications and defining detailed technical solutions and business cases. Manufacturers can then derive a target picture of advanced automation that employs innovative technologies to improve quality or maximize savings on conversion costs. An agile, cross-functional approach is essential to implementing initiatives across systems.

Limitations of Conventional Technology

Since the late 1960s, factory automation has relied on programmable logic controllers (PLCs), which apply adjustable programs and measurable inputs to control machines. PLCs are very useful for automating repetitive processes that do not entail much variation. However, in their standard configuration, they are not good at adjusting to unforeseen events or adapting automatically to variations.

The reason for this is that conventional PLCs utilize static programming to enable a rule-based approach to automation. Programmers attempt to model all the situations that a machine, such as a robot, could encounter and then define a set of rules to address them. But while these rules can work well in narrow or clearly defined environments, accounting for every real-world situation is often impossible. As a result, if a machine encounters a situation that requires a deviation from the planned behavior, it enters failure mode and production stops. Programmers must then adapt the rules to accommodate the new situation—or hope that it does not recur.

Technological Advances Offer a Breakthrough

Six recent technological advances enable manufacturers to overcome the barriers to greater automation. Many were initially deployed in consumer applications and are now being tailored to industrial use.

Artificial Intelligence and Machine Learning. Artificial intelligence (AI) and machine learning make it possible to use data from sensors (such as vision systems) to program the computerized models that control robots. Recent advances, such as unsupervised learning, offer the potential to substantially reduce the amount of training data required to develop high-quality models, as well as the time and effort required to collect the data.

Closing the automation gap can yield labor and quality improvements that reduce conversion costs by up to 25%.

Simulation. New simulation environments utilize realistic physics engines (originally developed for video games and movies) to train the AI and machine learning models used for robotic movements. They make it possible to simulate millions of different environmental conditions, accelerating the development of AI and machine learning solutions and improving accuracy.

Cloud. The cloud provides a central training environment for AI and machine learning models and allows for quick scaling and deployment of control programs across all robotic stations where needed. It also provides centrally stored, up-to-date information—such as data relating to preceding operational steps—accessible from anywhere on the shop floor. Virtual tools are also accessible via the cloud, including digital twins that hold specific information about every product, such as tolerances that equipment must adjust for at each production step. Additionally, cloud computing enables massive amounts of flexible and scalable high-performance computations. Computation clusters can be set up within minutes with thousands of nodes. The total cost of these computations is a fraction of the traditional expense.

Edge. Edge systems (on or near the shop floor) aggregate data, enable bidirectional data streaming between the shop floor and the cloud, and connect sensors. These systems also execute algorithms (in the form of source code) on the shop floor, reducing latency and improving reliability. Managing these systems via the cloud facilitates the use and deployment of source code. Edge capabilities allow manufacturers to retain elements of their network architecture while replacing outdated technology.

System on a Chip. A system on a chip—a microchip that integrates all the electronic circuits and parts required for a given system—provides high performance, superior power management, and integrated security. It can be used in edge devices as well as in sensors and actuators. In combination with modern virtualization technology, a system on a chip can execute AI and machine learning models, graphical user interfaces, and edge functionality. This enables a major shift from hardware-based to virtual, software-defined PLCs. A system on a chip also allows for the integration of PLCs and the human–machine interface, thereby accelerating efficient data transmission, reducing capex, and improving performance.

5G and WiFi 6. Advanced networking technologies, such as 5G and WiFi 6, can connect a variety of time-sensitive devices—such as sensors—reliably and securely on the shop floor. Time-sensitive networking is required to ensure that robots have the correct data as soon as they need it.

Overcoming the Barriers

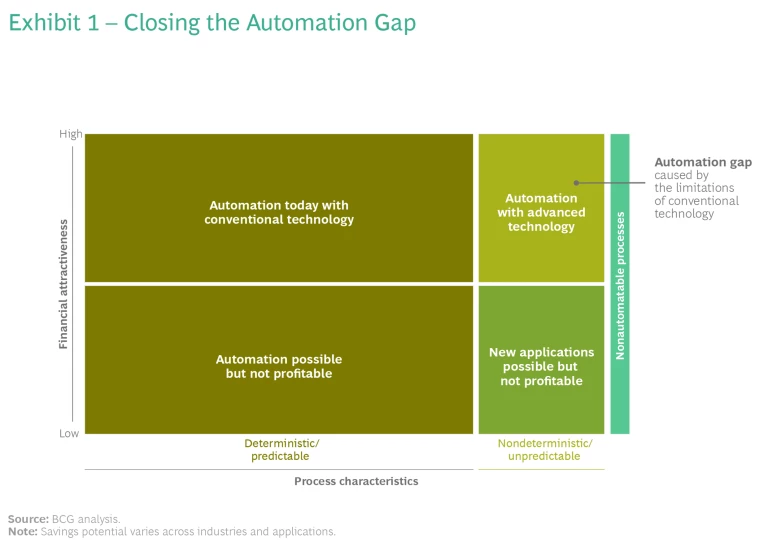

Manufacturers can use robots, sensors, and other advanced equipment powered by the smart combination of these technologies to address the barriers to automation, which we have organized into five groups. (See Exhibit 2.) Here is an overview of the possibilities.

Handling of Geometric Variances. Automated equipment must be highly adaptable to unpredictable variations in the geometry of components—such as variations in the curvature of glass that occur during thermal windshield production or leather wrinkles caused during the assembly of car seats. Although traditional automation can, in some cases, collect information about geometric variances, it isn’t able to react to or properly adjust to all possible variations. Consequently, equipment often cannot grab, hold, move, or attach physical objects on the shop floor.

Today’s advanced automation can provide the required flexibility. A tactile robot—equipped with a vision system and executing machine learning models on its internal computer—can teach itself to handle the geometric variances it encounters. The robot is connected to surrounding edge systems by a 5G network. By enabling time-sensitive and low-latency execution, the network allows the robot to operate safely in the shop floor environment.

Handling of Flexible Components. Unpredictable component deformations, changes in orientation, or structural instability increase the complexity involved in handling flexible objects, such as elastic tubes or electric cables. Imagine a cable swinging in the air: a human can apply his or her real-world experience in order to grasp such an object. A machine, in contrast, would have to inspect both the cable and the surrounding space and then predict the cable’s movement before it could grab and handle it—which is almost impossible with conventional rule-based programming. Newly developed vision systems and machine learning models, connected to robots enabled by real-time computer execution and high-speed networks, make it possible to perform such tasks.

Handling of Product Variant Complexity. The increasing number of product variances (such as in different car models) and tools used in assembly (such as for different-sized screws) requires highly flexible manufacturing equipment. In conventional setups, the frequent introduction of new variants necessitates the manual reprogramming and adjustment of automation devices. In fast-changing product environments and in new-product launches, this results in significant disruptions to production processes. A potential solution is the use of simulation environments to teach smart robots to cope with product variants. However, real-world conditions—such as friction, elasticity, and dynamics—are extremely difficult to measure and model in simulations.

A new technique called automatic domain randomization seeks to close the gap between real-world and simulated environments. It creates a variety of simulated environments with randomized properties and trains a machine learning model to work across all of them. By mimicking many different conditions in the environment, the randomization makes the model more resilient and flexible.

Efficient and Safe Collaboration Between Robots and Humans. Collaborative robotics is a growing field within industrial robotics, but it faces fundamental challenges. To interact effectively at regular speeds with workers on the shop floor, so-called cobots must automatically detect and identify workers’ activities, interpret human actions, and be proactive. This requires knowledge about the environment and the tasks that workers are performing. Because cobots lack the necessary contextual understanding of their environment, they need to operate at relatively low speeds—which has limited their application and adoption.

For the first time, the required technologies—and the skills needed to implement them in combination—are available to overcome many long-standing barriers to automation.

Conventional vision systems help somewhat: robots can operate at higher speeds when they do not detect any humans or objects in close proximity and then slow down when they do.

Cobots gain the ability to interpret and make more nuanced adjustments to human movements, so they can safely maintain higher speeds even when people or other objects are nearby. Labeled industrial data is used to teach an algorithm to recognize certain objects and conditions (or their absence) in images and videos. In addition to humans, this includes tools or hazardous conditions from which people should keep away. An effective data collection and selection process is a prerequisite to labeling, and the accuracy needs to be verified by robust quality assurance.

Challenging Process Sequence. Assembly operations can be complex and require special skills. For example, pulling a protective conduit onto electrical cables requires two hands, connecting cables requires vision and a sense of force, and opening a barrel requires knowledge of the procedural sequence. Conventional technology uses descriptive programming, with every potential process step and every possible action hard coded. But despite this comprehensiveness, the resulting process often does not match real-world conditions. Again, automatic domain randomization offers a solution. Using randomized physical parameters to simulate real-world conditions, the technique trains models to learn challenging sequences and build the experience needed to address them.

A Four-Step Approach to Close the Gap

In addition to selecting solutions for self-adapting mechatronic systems, companies need to make complementary changes to products and organizational systems and the IT setup. To enable greater use of automation, they need to change product designs and ensure a closer collaboration between engineering and manufacturing. They also need to revamp IT systems to ensure data exchange, deploy cloud and edge solutions, and power AI and machine learning models. Advanced automation lies at the intersection of these three systems. (See Exhibit 3.)

To close the automation gap, manufacturers should develop and implement a target picture of advanced automation that encompasses all the systems involved. The process entails four steps:

- Identify and prioritize high-value applications. Identify value leakages on the shop floor, such as quality issues that result in scrap or frequent unplanned production stoppages caused by equipment failure. Then compile a full list of processes where automation could be applied in the near term to prevent those leakages, and prioritize the applications based on the value at stake.

- Develop solutions and quantify business cases. Determine which technical solutions (that is, devices and systems employing the innovative technologies we have described) are needed to stop the value leakages relating to the prioritized applications. Assess all the required changes to products (employing design for automation principles), as well as the IT changes (such as new infrastructure) required to enable the selected solutions to generate the expected value. Finally, consider the necessary organizational changes —such as capability building and promoting closer collaboration between engineering and manufacturing. It will then be possible to estimate the total capex and other costs required for implementation and to quantify the business case for investment.

- Derive an advanced-automation target picture. Value is maximized by implementing the prioritized applications in combination rather than as individual use cases. Create a holistic target picture of advanced automation that shows how the applications will operate together at the company level and be scaled to the entire network. It should specify the full benefits of the implemented solutions as well as the synergies that can be captured across the network—such as by deploying the required IT capabilities at scale.

- Implement in agile, cross-functional teams. Develop an implementation roadmap by setting the sequence of initiatives across systems. An effective implementation follows an agile approach in which teams use short sprints to quickly develop and test minimum viable products that are refined based on frequent performance reviews. To avoid the limitations of a siloed approach, teams should comprise people from across functions—including product development, engineering, manufacturing, IT, and other auxiliary functions.

Quantifying the Impact

Closing the automation gap allows companies to improve costs (by reducing the need for manual work) and quality. BCG quantified the potential impact in a recent study of a pump manufacturer that uses a high level of automation compared with its industry peers. The manufacturer’s assembly process has approximately 250 distinct steps, each of which could encounter some or all of the five potential barriers discussed above. We matched each process step to the latest technology available and assessed the feasibility of changes to products, to the organization, and to IT systems that would enable additional automation. The combined changes allowed us to create an advanced-automation target picture.

Comparing the target and current states, we found that the company could raise its already high level of automation substantially. This would allow it to reduce conversion costs by 25%—which is significant, especially for advanced industries.

The automation revolution in manufacturing has finally arrived. For the first time, the required technologies—and the skills needed to implement them in combination—are available to overcome many long-standing barriers to automation. The six innovative technologies we have described provide machines on the shop floor with enhanced capabilities, such as self-learning and data processing. By smartly combining these technologies, companies can empower equipment to perform many tasks that were too complex for conventional automation or were not feasible to automate. Manufacturers that lead the automation revolution will be the first to realize the promise of the highly automated factory and capture a sustainable competitive advantage.