Both NASA and the European Space Agency are pushing ahead with plans for 3D printing on the moon and the International Space Station.

The aim is to build housing, infrastructure, tools, or spare parts that are needed to advance space exploration , potentially using space dust or rock as a raw material.

Private space companies are also researching and developing similar use cases.

The So What

“The acceleration of space applications for 3D printing is driving broader progress within the industry, both in terms of the flow of investment and the advance of the technology,” says BCG partner Wilderich Heising , who specializes in additive manufacturing.

BCG estimates put the value of the 3D printing industry in 2022 at around $18 billion, and it is projected to grow to reach $95 billion by 2032.

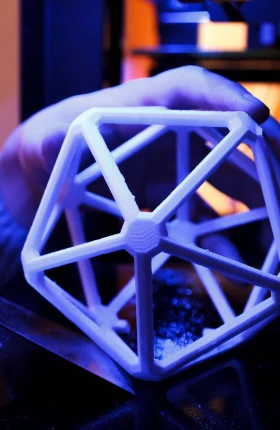

3D printing is a technique to create an object from a digital file by adding successive layers of material until the object is formed.

Examples of existing use cases include lightweight structures such as aircraft parts, and medical or dental products where customization is needed.

“We are on the verge of 3D printing becoming a further technology in the toolbox of manufacturers for producing end-use parts across multiple industries,” Heising adds.

“Space will be the ultimate demonstration of distributed manufacturing. In the ‘old world’ you were dependent on factories to supply products, whereas 3D printing allows the printing of products near to where they are needed, for example, in space, on oil rigs, or at remote aircraft maintenance sites across the globe.

You won’t necessarily need a traditional base for manufacturing—you can produce what’s needed anywhere in the world, or even beyond it.”

Now What

According to Heising, 3D Printing in Space will take off

- “Given the rate of progress so far, I am confident that the challenges of space will be overcome. The value proposition is clear and I believe 3D printing in space is likely to become a reality within the next 5–10 years,” Heising says.

But it will exist alongside conventional manufacturing

- By 2040, 3D printing will be significant, but it won’t crowd out traditional manufacturing. Rather it will make up 1%–2% of the world’s global manufacturing market.

In Space, there are specific challenges to overcome:

- The use of certain materials will be restricted as the chemical make-up of some materials can change in the harsh environment.

- Getting printers to function in a near-zero gravity environment and with the absence of pressure is not a trivial task.

Nevertheless, there are clear benefits and a value proposition:

- Obtaining spare parts or building materials much faster and at a much lower cost than having to transport goods from Earth.

- The additive nature of 3D printing means little waste is generated, eliminating the problem of waste disposal in space.

Back on earth, the 3D printing industry should:

- Shift its focus from prototyping to identifying the right manufacturing applications and then supporting the manufacturer to use the technology. Rather than providing one-size-fits-all printers, manufacturers need plug-and-play printers which can be connected to factory systems and print without the further need for engineering and adaptation.

- Put the user in the foreground and focus on providing solutions to the pain points of manufacturing. Rather than simply demonstrating technical capability, the industry must start with existing problems and then provide solutions that create value for the user of the technology.