It’s an issue that’s increasingly vexing CEOs as the world becomes more uncertain and complex: Why haven’t digital technologies made business planning better, faster, and easier? Why don’t plans survive the first contact with reality?

The COVID-19 pandemic and its long aftermath exposed numerous gaps in business planning. Many companies have been trying to strengthen their planning capabilities—with decidedly mixed results. Functions and business units often continue to plan in silos, and the assumptions behind most forecasts still aren’t transparent. So top management teams continue to find it tough to reconcile plans across organizational levels and time horizons.

To tackle these challenges, companies are increasingly turning to integrated business planning (IBP) platforms that are driven by artificial intelligence (AI). Traditional IBP used enterprise resource planning platforms that were supplemented by data from other systems, and it was mostly a manual process in terms of data aggregation and forecasting. Difficult to coordinate, IBP was hampered by a lack of trust in the data and opacity. It also had few predictive or optimization capabilities.

Today’s AI-driven IBP platforms help companies create a rich data fabric, an automated planning process, and algorithm-based decision support. Available as software as a service (SaaS) packages or as an orchestrated solution, investing in AI-driven IBP can result in a 2 to 4 percentage point annual increase in revenues, a 2 to 3 percentage point decrease in costs, and a 15% to 30% reduction in inventories, on average. Besides, using IBP increases job satisfaction by making work more systematic, which frees up time for strategic tasks and innovation.

But an AI-driven IBP system isn’t easy to design or deploy. It’s also a major investment. The cost can run into tens of millions of dollars, often exceeding $100 million for large corporations—and that doesn’t include the time and internal resources needed for its implementation. In our experience, many companies that have implemented AI-enable IBP platforms say that they didn’t realize as much value as they had hoped to, mainly because of a poor adoption rate, misaligned processes, and the lack of connectivity between IBP tools.

Modern IBP solutions must seamlessly integrate people, processes, and digital technologies—the trinity of effective end-to-end planning. In this article, we focus on the role of technology.

The Power of AI-Enabled IBP

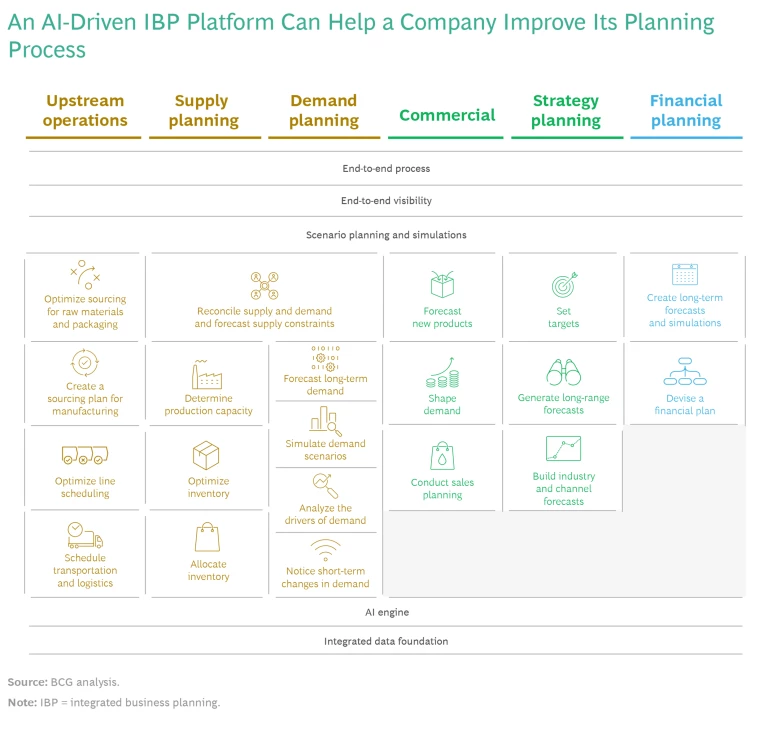

AI-driven IBP platforms help companies improve business planning in several ways. Chiefly, they create a planning process that extends from end to end in an organization. The platforms connect upstream planning, such as supply chain planning, with downstream planning, such as demand forecasts, commercial planning, and financial forecasting. (See the exhibit.)

At a minimum, these platforms also automate planning, and they potentially enable planners to make better decisions with predictive and prescriptive analytics. Companies can migrate from manual to automated forecasting and gain the capabilities for scenario planning as well as real-time simulations. The latter shift the planners’ focus from numbers to identifying the key risks and opportunities. As a result, the planning process becomes faster, easier, and better.

Faster. AI-driven IBP platforms use automated data feeds and AI-driven forecasting models, shortening the time needed to develop forecasts. Automation minimizes the number of planning iterations, while the use of objective parameters for data eliminates the need for endless discussions. Migrating to an automated IBP platform enables companies to cut planning cycle times by 30% to 40%, while the ability to use signals-driven forecasting ensures that companies can prepare for and execute faster organization-wide responses to change.

Easier. AI-driven IBP solutions also ensure that companies can align—in real time—demand, supply, and financial plans using common data sources. The process works across functions, business units, and teams, so companies can resolve the risks involved in not fulfilling commitments as well as identify opportunities to bolster growth. And since the process is usually automated, there’s little need for using Excel spreadsheets or crunching numbers anymore.

Better. By connecting demand forecasts and supply scenarios, AI-enabled IBP provides better visibility into operating constraints, allowing companies to close gaps either by increasing supplies or reshaping demand through promotional and marketing efforts. And end-to-end visibility reduces supply chain costs by ensuring more efficient logistics, lowering warehousing expenses, and improving order management. As a result, IBP platforms improve the accuracy of forecasts by as much as 25 percentage points and typically by at least 10 percentage points.

Getting AI-Driven IBP Right

Implementing an AI-enabled IBP platform is a challenging journey that requires building a data foundation and using AI-powered analytic models to automate planning. An implementation also necessitates orchestrating technology across systems and upskilling the organization. Companies should take five steps to be successful.

Harness all data. An AI-driven process demands large quantities of data that is as fresh as possible. It also needs different kinds of data, which could take the form of standard inputs as well as early-warning signals. Smart companies draw on a variety of data; the leaders use as many as 15 to 20 data sets for demand planning alone. An end-to-end IBP solution also involves hundreds of internal and external signals, which makes data one of the key challenges in automating planning.

Creating an IBP process requires merging, harmonizing, and automating inputs from many internal and external sources.

Creating an IBP process requires merging, harmonizing, and automating inputs from many sources, both internal and external. Some internal sources will be easy to integrate; however, a lot of the data may not be centrally stored, let alone automated. Promotion data, for instance, often exists only in spreadsheets on sales teams’ laptops, so it can be tough to access it in a timely fashion. If data sources haven’t been centralized, an organization should use manual workarounds in the short term and automate the data flows in the long run. The challenge with externally sourced data is identifying the right signals and finding reliable data sources.

While many SaaS IBP platforms boast of data integration capabilities, being able to use multiple sources of data isn’t enough. Planning becomes better only because of the systematic cleaning, understanding, and enrichment (through manipulation) of the most important data sets. Raw data fed into machine learning models will marginally improve the performance of business planning models, but data transformation boosts accuracy by at least 10 percentage points. That’s why when implementing a SaaS platform, wise companies deploy more systematic and rigorous data governance systems, and they build data capabilities to analyze and extract results from data sets.

As the first step of its migration to IBP, for example, a beauty products player created an integrated data foundation for demand planning. It found, aggregated, and harmonized data from 14 sources: shipments, orders, and inventory databases; three sell-out databases; two databases for historic and planned marketing efforts; distribution and promotional databases; a weather service; and sources for COVID-19 incidences, macroeconomic data, and consumer price trends. Many sources didn’t have owners and the data quality was dubious, so the company created and applied governance standards to ensure that the data was reliable. By using quality data and developing algorithms to forecast demand for different time horizons and granularity levels, the company was able to boost its bottom line by 2% per year.

Orchestrate the solution. Many SaaS IBP platforms promise to eliminate planning-related problems; CEOs, chief technology officers, and chief information officers would do well to carefully evaluate prospective solutions to find one that addresses their specific challenges.

Using a single out-of-the-box package as the basis of an IBP solution sounds good in theory, but it is usually problematic in practice, especially for large companies since the implementation can be complex and time consuming. Moreover, business units and functions typically have invested in systems that don’t talk to each other. For these reasons, SaaS IBP platforms will have to be orchestrated solutions that connect existing systems, close the gaps, and integrate them into an end-to-end platform.

A large company whose sales exceed $15 billion bought a supply planning platform, a trade planning system, and a financial planning solution, each from a different vendor for a total investment of about $100 million. None of the solutions were set up to integrate with each other. While the supply plans and demand forecasts were drawn up in terms of volumes at the SKU level, the financial plan projected income and expenses at the business unit level. The trade planning solution went largely unused by the sales teams, which continued to rely on the plans they built in spreadsheets. The only way forward was to evaluate each system, identify the problems and gaps, and develop fit-for-purpose software to integrate them.

Customize algorithms and scenario and forecasting models. Although most out-of-the-box IBP systems come with some forecasting capabilities, off-the-shelf algorithms are far from optimal and will often be less accurate than customized ones. We find that using custom algorithms improves the accuracy of forecasts by 5 to 20 percentage points.

Using custom algorithms can improve the accuracy of forecasts by 5 to 20 percentage points.

Rapid scenario planning—one of the most desirable features of an integrated planning system—increases the value of demand planning exponentially. In complex and connected industries, the ability to quickly understand the tradeoffs while making decisions is a major benefit that IBP provides.

Forecasting transparency is another desirable. Most planning forecasts are still black boxes, providing only basic insights into the relative weight of different inputs or making simple attributions to their drivers. That doesn’t foster trust among decision makers; only customized forecasting models can provide a level of transparency that is in line with the expectations of decision makers. Such models offer more visibility into the inputs used for drawing up forecasts, the assumptions made about execution, and the level of uncertainty in the forecasted numbers. This level of visibility not only builds trust but also provides actionable insights about the levers that executives can use to deliver better results.

Customized generative AI systems will turbocharge AI’s role in IBP in the future. A generative AI system could near-instantly scan through thousands of data points and provide insights, in natural language, about past changes in sales trends, the outliers in historic data, the reasons for sales acceleration or deceleration, and new growth opportunities. The technology could also be used to enhance data quality and enrich it with product attributes (from, say, photographs), as well as tune and update AI-based planning models. Generative AI may also help executives envision novel human-machine interfaces for planning, such as conversation-based ones.

Manage the transition patiently. Shifting to an AI-driven IBP platform will require extensive employee training across functions and organizational levels. Employees have to get used to the new ways of working and learn to trust the new process, and that will take time. Companies should start small, generate value early, and give their nascent capabilities the time they need to mature. Transitioning to an IBP process can be executed in sprints, but institutionalizing it is a marathon that requires the top management teams to stay the course.

Managing IBP-related change poses two key challenges. The first is fostering collaboration between previously unconnected functions, which requires redesigning the planning process as well as better aligning goals across functions. Stakeholders need to understand how the new process will benefit them and what implications it will have on their day-to-day work to make the transition. The shift also demands redistributing power and accountability that, in turn, needs careful management and constant communication by business leaders to the entire organization.

The second hurdle is getting business planners to adopt AI-driven IBP. Planners, who often have been in their jobs for decades, may have reservations about shifting to AI-driven models. In addition, many don’t have an analytics background, so they may not understand how the new models work. Like employees in other sectors, many may feel threatened by the technology, believing that it will sooner or later make their jobs redundant.

Companies need to communicate that analytics and automation won’t replace planners but will augment their power.

Explaining how AI models function when training business planners is a crucial first step. Companies also need to communicate that analytics and automation won’t replace them but will augment their power. Technology can take on the routine, calculation-intense parts of forecasting so that planners can shift to reviewing exceptions and adjusting for critical parameters, such as hero SKUs (products whose volumes or profits are crucial to the business), important promotions and campaigns, and new product introductions. Consequently, business planning meetings can shift from a my-number-versus-your-number debate to identifying fresh opportunities and developing risk mitigation strategies.

By way of illustration, a multinational company with three main product lines wanted to shorten its seven-week planning cycle, adjust to demand signals more quickly, and have a rationale for allocations at times of shortages. It therefore invested in an AI-enabled IBP platform that it could customize by product line, distribution channel, and region. The company piped in data from more than 40 sources and created a data management and governance system for which it trained more than 100 employees. To ensure that the platform would be used, the company conducted 15 training sessions across the globe for more than 200 users at a time. After it had completed the transition to the new system, the company reckoned that using IBP had increased revenues by about $50 million and reduced working capital requirements by $100 million a year.

Ensure top management teams’ support. Shifting to AI-driven IBP platforms can noticeably improve both the top and bottom lines. That’s why smart business leaders treat IBP not just as a new planning process but as a company-wide initiative to boost performance.

Top management teams’ involvement is critical to help create the vision, draw up the objectives, and ensure that the organization is aligned around them. Business leaders’ support will also be needed to break down the barriers between functions and business units, rethink business processes, and change the way executives have traditionally developed business plans. They must demonstrate their commitment to an IBP platform by sponsoring capability-building efforts and agreeing to own the decisions to which the new planning process leads them—regardless of the consequences for their function or unit.

A consumer products company recently transformed its planning by unifying its sales, demand, supply, and financial planning processes into a single process. Led by the chief operating officer (COO), the initiative’s main objective was to unlock growth opportunities by creating a planning process that focused on each business unit’s performance, rather than on the objectives of each function. This overhaul required shifting some responsibilities, roles, and authority in each of its businesses. The COO’s involvement was critical to set planning goals and to ensure alignment across the organization about the use of IBP. Partly as a result, the business units that implemented the new system boosted revenues by 2%, improved forecast accuracy by up to 15%, and shortened the time taken to finalize business plans by more than 30%.

Stay ahead with BCG insights on artificial intelligence

As uncertainty shrouds the global economy and technological change accelerates, business planning will become more relevant—and complicated. To stay ahead, CEOs have to invest in developing planning capabilities that seamlessly integrate people, processes, data, and technology across functions. Only such a transformation will enable companies to adapt rapidly to changing demand and supply conditions, gain visibility into risks and opportunities early, and ensure that every part of the organization is striving to achieve the same goals. After all, a company without an integrated business plan will find that every road it takes leads it nowhere.