The following insights are part of BCG’s Build for the Future series, based on three years of research conducted on digital transformations at major organizations around the globe.

Manufacturers face a tough set of challenges right now. They need to boost productivity in their factories, but also reduce their environmental footprint . They have to be more flexible and adaptable to successfully respond to rapidly changing market conditions. And they are struggling to recruit, upskill, and retain top talent. Tackling any one of these challenges is hard; addressing them all requires a new approach.

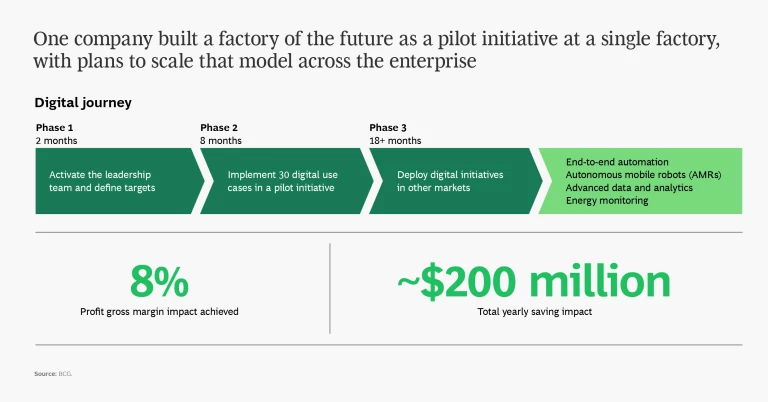

BCG has assembled a large and growing body of research about how manufacturers can dramatically improve performance across all these dimensions. We call it the factory of the future (FoF). Manufacturers worldwide have already started applying these ideas, and they are already seeing results. (See “Build for the Future.”)

Build for the Future

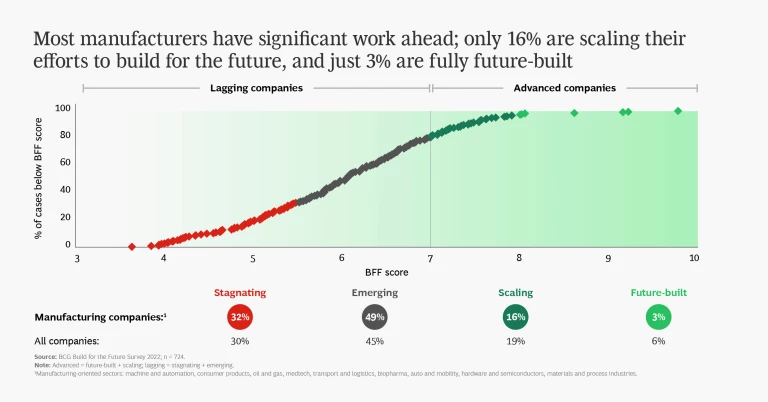

Our latest survey asked all participants about five areas that are fundamental to success, the emphasis of transformation efforts, how successful they have been, and the degree to which each of more than 50 potential influencing capabilities were in place. We then used the resulting data set to analyze which combination of capabilities, if built sufficiently well, had the biggest impact on future readiness and which combination differentiated future-built organizations from those facing a greater risk of disruption. Six attributes emerged from this analysis and, in our judgment, serve as the best descriptors for leading companies.

From this research, we identified the path that companies must take to become built for the future. We’ve reconciled the challenge of what these companies need to do (identifying which initiatives drive the most value by sector) with how to do it (determining which capabilities drive success and how to build them fast). CEOs can tailor this new playbook to their company-specific change agendas. Learn more about our Build for the Future campaign here.

Needed: A Comprehensive Approach

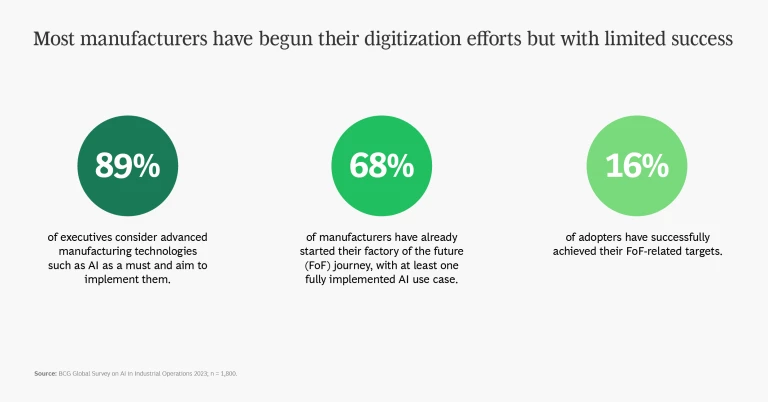

Most manufacturing companies have launched digital initiatives in their facilities, but these are often isolated initiatives that are not sufficiently comprehensive. Consider that in a recent BCG survey of 1,800 executives, 89% regard advanced manufacturing technologies like AI as crucial, but only 68% have implemented at least one AI use case, with a mere 16% successfully achieving their targets.

Instead, manufacturers need a broader and more strategic approach to fundamentally change performance on the shop floor: the factory of the future.

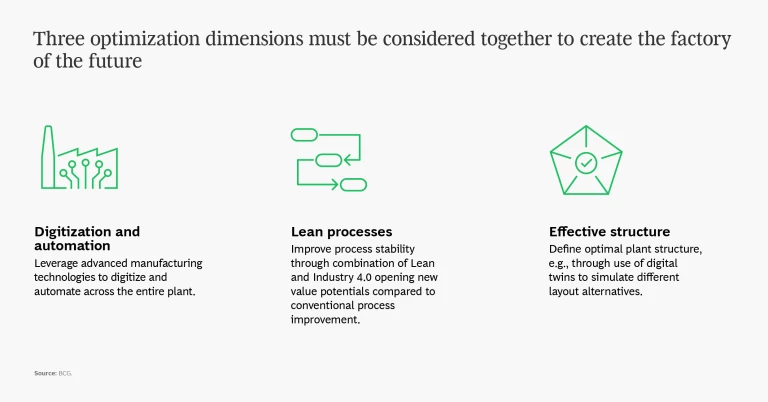

- Five critical elements make up the FoF approach: the optimization dimensions of digitization and automation, lean processes, and an effective structure, along with a foundation of people and technology infrastructure.

- More than 50% of manufacturing executives rated improvement potential across all major challenges—productivity, sustainability, flexibility, and talent—through the FoF approach.

- Most manufacturers have significant work ahead. Only 16% are scaling their efforts to build for the future, and just 3% are fully future-built.

Core Elements of the Factory of the Future

Building the factory of the future is a significant task that involves focusing on three optimization dimensions—along with two foundational dimensions—to continuously improve the factory.

Optimization Dimensions

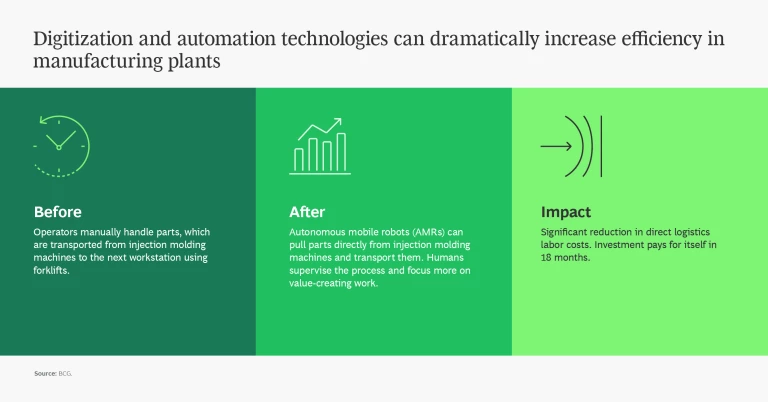

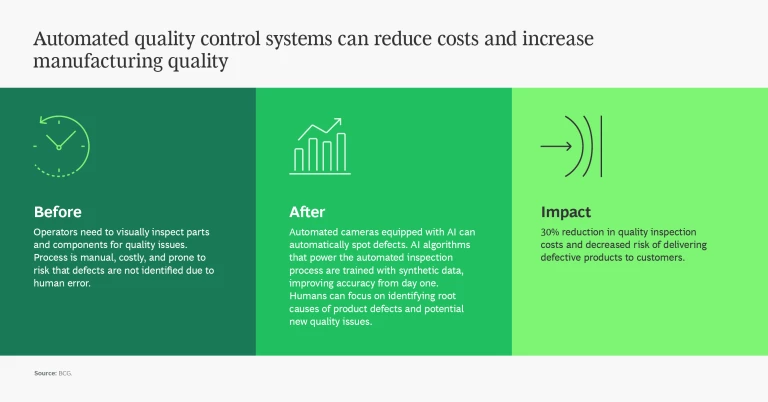

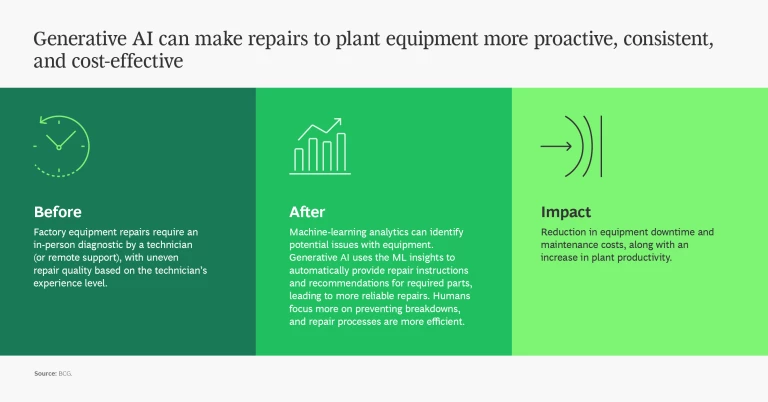

- Digitization and Automation. Building real-time transparency, increasing predictability, and automating plants via self-controlled systems.

- Lean Processes. Improving plant processes through lean principles in combination with Industry 4.0.

- Effective Structure. Adapting the plant’s structure and layout in terms of assets, walkways, inventory positioning, particularly to support flexibility and agility.

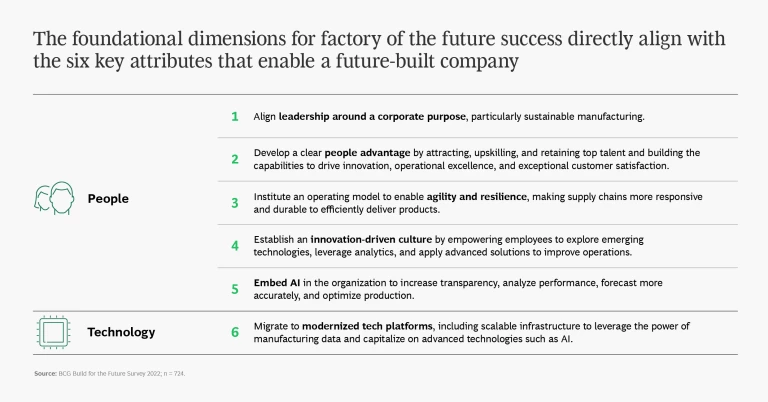

Foundational Dimensions

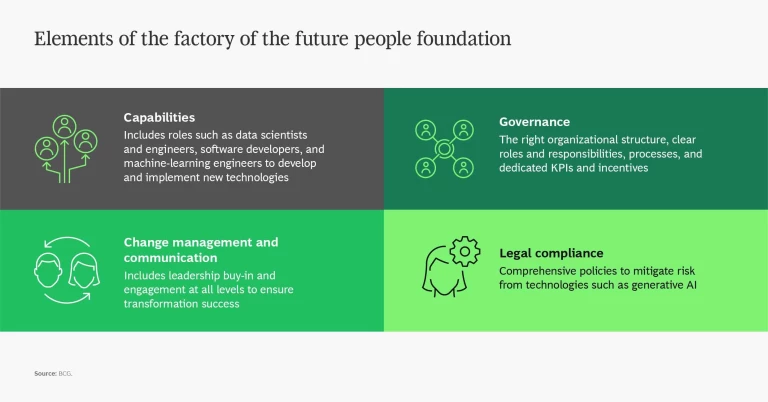

- People. Recruiting the right talent, upskilling the workforce through capability-building programs, creating the right governance (including organization structure, roles and responsibilities, processes, and incentives and KPIs), and developing a strong change management and communication strategy.

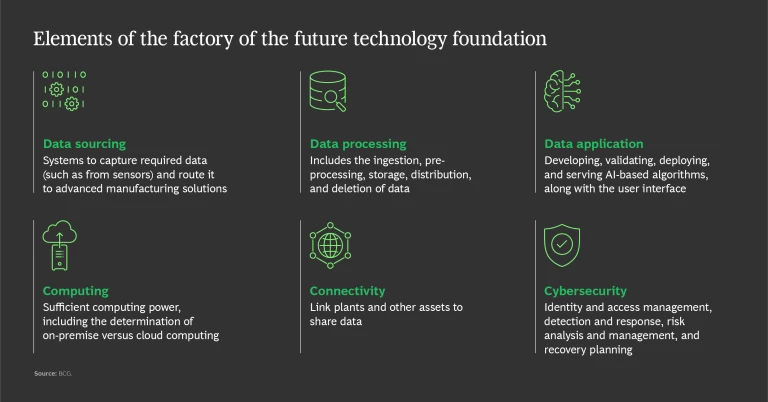

- Technology. Building the right tech stack; assessing and selecting the right providers for required hardware and software.

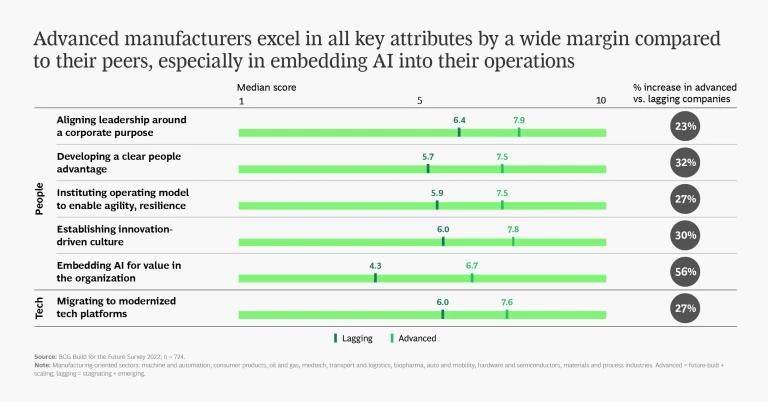

These foundational dimensions for FoF success directly align with the six key attributes that enable a future-built company: aligning leadership around a corporate purpose; creating a differentiated people advantage; building an agile and resilient operating model; fostering an innovation-driven culture; embedding AI in the organization; and migrating to modernized tech platforms.

All optimization and foundational dimensions need to be considered holistically and cannot be addressed on their own.

Measurable Gains on the Shop Floor

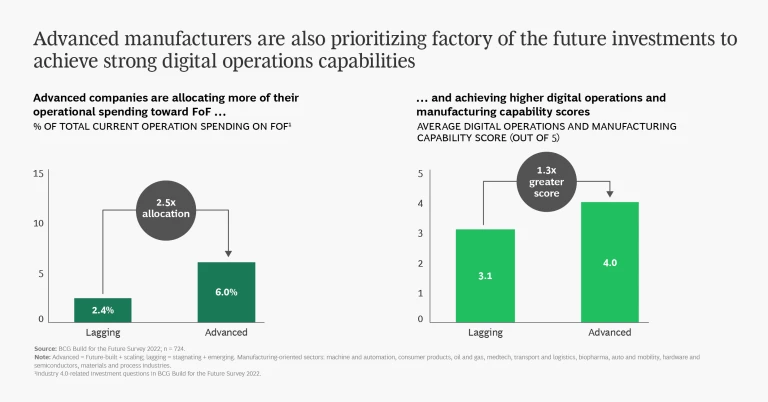

What sets top performers apart? In our analysis, advanced manufacturers lead their peers across all six key attributes by a significant margin, particularly in embedding AI into their operations, where they excel by 50%. They also allocate resources to projects that will pay off. Specifically, advanced companies allocate 2.5 times more of their operational spending toward FoF initiatives compared with their peers, resulting in digital operations and manufacturing capability scores that are 30% higher than those of their peers.

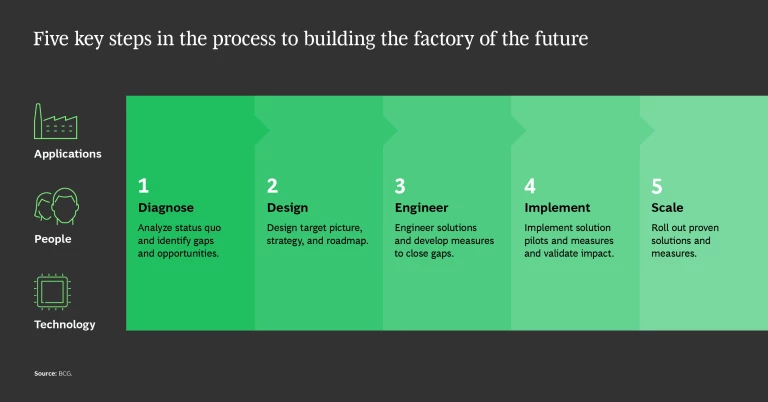

Learn more about what it takes to build the factory of the future in the slideshow below.