Large capital projects are inherently complex and risky because they typically entail substantial financial investments, extended timelines, and intricate coordination among stakeholders. The complexities are amplified in projects that involve emerging decarbonization technologies—such as those in the power-to-X (PtX), green steel, and green cement sectors.

These large green projects are critical to achieving global decarbonization goals and are poised to become major sources of competitive advantage. But their economic viability remains uncertain. For instance, green initiatives often rely on emerging technologies that have not yet been proved at scale and require new types of infrastructure. They also must comply with diverse and evolving environmental regulations in different regions. (See “Green Projects Amplify Complexity and Uncertainty.”)

Green Projects Amplify Complexity and Uncertainty

The complexities are amplified in large green projects because scaling up operations must be synchronized with the adoption of often-untested technologies. From among more than 600 large capital projects we have supported across diverse sectors over the past five years, we have analyzed the challenges and lessons learned for three types of complex large green initiatives:

- PtX. PtX technologies, which convert renewable electricity into hydrogen, ammonia, and other chemicals, are poised to play a critical role in the energy transition. According to our analysis, the global market for low-carbon hydrogen could reach $1 trillion by 2025, driven by its potential to decarbonize various industries.

- Green Steel. The steel industry, responsible for approximately 8% of global CO2 emissions, is under significant pressure to reduce its carbon footprint. Innovations such as hydrogen-based ironmaking are gaining traction, but their large-scale adoption requires substantial investment and infrastructure development.

- Green Cement. Cement production accounts for about 7% of global CO2 emissions. The industry is exploring various decarbonization pathways, including the use of alternative materials, energy-efficient production processes, and carbon capture, utilization, and storage (CCUS).

- Commercial Uncertainties. The market for green products is still evolving. Offtakers are hesitant to commit to long-term agreements without clear standards and assurances of quality and sustainability. For instance, green steel projects are currently awaiting industry-wide acceptance of carbon-free steel as a premium product. Without committed buyers, developers struggle to present a convincing business case to investors.

- Operational Uncertainties. The infrastructure required to support renewable-energy sources and alternative raw materials is often underdeveloped. Green steel projects involving electric arc furnaces (EAF), for example, struggle to secure a steady and reliable supply of renewable energy, while hydrogen-based green steel projects must cope with an underdeveloped hydrogen infrastructure. Moreover, there is limited access to alternative green raw materials, such as scrap steel or iron produced via low-carbon methods. The absence of reliable supply chains increases operational costs and threatens the continuity and efficiency of production processes. These operational uncertainties boost the capex required to build and maintain the necessary infrastructure, as well as raise operational costs owing to inefficiencies and supply chain disruptions.

- Regulatory Uncertainties. The regulatory landscape for green technologies is complex and constantly changing. Moreover, different regions have varying standards and timelines for implementing carbon reduction measures. Europe is leading the way by enacting the Carbon Border Adjustment Mechanism. But companies in North America and Asia face less regulatory pressure to invest in green technologies. PtX projects, for instance, encounter disparate hydrogen regulations across different jurisdictions. This regulatory inconsistency complicates planning and execution and introduces risks of noncompliance as well as potential fines, all of which can deter investors.

Each of these areas presents specific risks that hinder projects’ ability to secure funding, manage costs, and meet timelines. For example, approximately two-thirds of global PtX projects and European green steel projects are behind schedule or at risk of delays. This figure rises to 90% for green cement projects in Europe. Such delays ultimately impact projects’ financial feasibility.

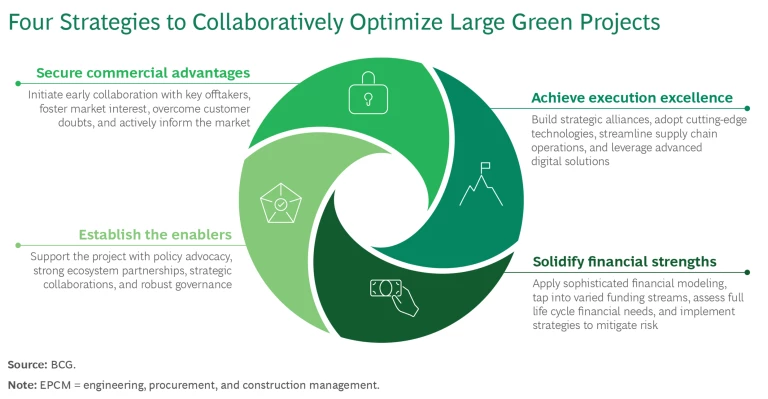

To overcome the challenges and set up project teams for success, developers need to adopt a fundamentally new approach to project governance and equip themselves with capabilities and tools that differ from those used in traditional large projects. By collaborating across the value chain, developers can ensure that projects secure commercial advantages, achieve execution excellence, solidify financial strengths, and establish the enablers to support project success. (See the exhibit.) This integrated approach not only mitigates risks but also leverages the strengths of each stakeholder to accelerate the project timeline.

Securing Commercial Advantages

To succeed commercially, companies need to engage early with offtakers, incubate market demand, address customer skepticism, and proactively educate the market.

To succeed commercially, companies need to engage early with offtakers, incubate market demand, address customer skepticism, and proactively educate the market.

In the green steel sector, for example, Stegra (previously H2 Green Steel) has demonstrated the importance of obtaining early commitments from offtakers. In 2020, the company launched a project that aims to produce 5 million tonnes of green steel by 2030. The project has attracted significant investments and secured long-term contracts by leveraging Stegra’s sustainability credentials. (See “Stegra’s Offtake Mechanism.”)

Stegra’s Offtake Mechanism

Stegra was launched in 2021 with the goal of decarbonizing the steel industry by producing green steel using renewable energy and green hydrogen. The company’s plant, located in Boden, Sweden, will utilize a giga-scale electrolyzer to produce green hydrogen, which will then be used to reduce iron ore to sponge iron through direct reduction. This method aims to cut emissions by up to 95% compared with traditional blast furnace methods.

To ensure a steady demand for its green steel, Stegra has strategically secured multiple binding offtake agreements with key industry players:

- Cargill Metals. Stegra signed a multiyear deal with Cargill Metals, a global leader in the ferrous supply chain. Cargill’s extensive network will help distribute Stegra’s green steel beyond Europe.

- ZF Friedrichshafen. A significant €1.5 billion agreement with ZF, a major automotive supplier, underscores the strategic importance of Stegra’s green steel. This seven-year deal will supply near-zero-emission steel starting in 2026, playing a crucial role in ZF’s efforts to decarbonize its supply chain and meet its climate goals.

- Kirchhoff Automotive. Kirchhoff supplies major automotive brands, including BMW and Mercedes-Benz. The company’s deal with Stegra, valued at $130 million, will commence in 2027. It involves not only the supply of green steel but also a commitment to recycle at least 30% of steel scrap back to Stegra’s facility in Boden.

The green cement industry similarly emphasizes the importance of demand incubation and offtake agreements. Securing early agreements with developers of large-scale construction projects that commit to using sustainable building materials is crucial. This strategy provides financial stability and drives broader market acceptance. Some European projects have benefited from regulatory frameworks that promote demand. For example, France’s RE2020 regulation sets limits on carbon emissions from construction materials and encourages the use of sustainable products.

Project developers must also address customer skepticism. The green cement sector faces challenges arising from the industry’s preference for traditional, proven materials. To overcome this, developing a coalition of cement producers to enhance the credibility and certification of new products is essential. Partnerships with insurance companies to provide coverage for buildings constructed with green cement can further build trust and market acceptance.

Effective market education and outreach are also critical. Highlighting the environmental and economic benefits of green technologies through industry conferences, case studies, and collaborations can significantly enhance market demand. For example, by showcasing the successful implementation of carbon capture, utilization, and storage (CCUS) technologies in green cement production, companies can demonstrate that green products offer tangible benefits without compromising quality.

Achieving Execution Excellence

Before reaching the final investment decision, green projects need to attain execution excellence through strategic partnerships, technology integration, efficient supply chain management, and the use of advanced digital tools.

Strategic partnerships with engineering firms and engineering, procurement, and construction management (EPCM) companies are essential to manage risks and ensure successful project execution. Given the high degree of uncertainty and complexity associated with large green projects, traditional contracting methods may not suffice. Innovative approaches, such as alliance contracting, are recommended for critical tasks that directly impact the project’s timeline. These methods foster collaboration and risk sharing, align incentives, and encourage a collective focus on project success.

Given the high degree of uncertainty and complexity associated with large green projects, traditional contracting methods may not suffice.

Developers can significantly mitigate risks and enhance project delivery by establishing risk-reward mechanisms in their contracts and selecting strategic partners with expertise in green projects. Tailoring contract strategies to each project’s specific needs and risk profile allows developers to navigate uncertainties more effectively and ensure timely, cost-efficient project completion.

Green steel projects exemplify the relevance of forming strategic partnerships with technology providers and contractors. A case in point is ArcelorMittal’s collaboration with Midrex Technologies to establish a direct-reduced iron (DRI) facility that leverages natural gas and hydrogen. (See “ArcelorMittal’s Partnership with Midrex Technologies.”)

ArcelorMittal’s Partnership with Midrex Technologies

The partnership entails building a demonstration plant engineered by Midrex Technologies. Initially, this facility will use gray hydrogen—made by capturing waste gases at the steel plant—to reduce iron ore and produce DRI at an industrial scale. The plan includes a transition to green hydrogen, derived from renewable energy, as it becomes more accessible and economically viable.

The demonstration plant is slated to annually produce approximately 100,000 tons of DRI, which will then be used in EAFs with scrap metal to further decrease the carbon footprint of steel production. The German federal government has allocated €55 million, funding 50% of the total capital expenditure, for the development and preliminary commissioning. Commissioning has been postponed to 2026, however, because of challenges in obtaining hydrogen following the dissolution of the Hamburg Green Hydrogen Hub.

Additionally, ArcelorMittal is considering hydrogen-based DRI ventures in Bremen and Eisenhüttenstadt. The European Commission has sanctioned a €1.3 billion grant by the German federal government, covering approximately half the total investment of €2.5 billion. The projects aim to start operations in 2026. ArcelorMittal has noted that competitive energy prices and sufficient hydrogen supply are essential for a positive final investment decision by mid-2025.

These initiatives and the associated funding form a key part of ArcelorMittal’s broader decarbonization strategy across the EU, bolstered by €3.1 billion in EU grants. This support is intended to establish 9 to 10 megatonnes of new DRI capacity and several CCUS demonstration projects.

Similarly, Algoma Steel’s partnership with GE Vernova to upgrade its operations to include an electric arc furnace (EAF) demonstrates the critical role of facility modernization in boosting efficiency and meeting environmental objectives.

Supply chain optimization is another critical aspect of execution excellence. It helps to ensure a reliable supply of essential inputs, such as alternative raw materials and renewable energy.

In the green cement sector, securing the long-term availability of alternative decarbonized raw materials or supplementary cementitious materials is crucial. Companies also must gain access to waste for use as fuel and invest in demolition waste processing. Other necessary steps to ensure a steady supply of renewable energy include decentralized power generation and securing power purchase agreements early in the project life cycle. These approaches not only support sustainability but also enhance the resilience and efficiency of project operations.

Digital tools play a significant role in enhancing operational efficiency. By implementing advanced analytics and AI-based models, developers can optimize technical and economic variables, improve their understanding of tradeoffs, and account for risks in different scenarios. They can also leverage market insights and advanced databases to visualize and analyze global production capabilities, helping them optimize asset configurations and improve operational efficiency.

AI-driven building information modeling (BIM), a rapidly evolving capability, could further enhance collaboration and planning for sophisticated large-scale projects and ultimately save time and costs. One prominent application example is Tesla’s Gigafactory in Berlin. The company has used AI-powered BIM to manage the constant changes in structural and equipment layouts, ensuring minimal rework and optimized construction schedules. This approach promoted the efficient completion of the Gigafactory project, with significant time and cost savings.

PtX projects in prefeasibility phases, for example, can benefit significantly from using advanced analytics tools for techno-economic analysis, integrating a probabilistic approach to optimization. These solutions have enabled project developers to optimize plant configurations, enhance operational efficiency, and secure better financial outcomes. BCG has helped developers use this approach to reduce project expenditures by up to 15% and improve net present value by an average of 10% to 15%. Such technology implementations also assist developers of green projects in effectively adapting to evolving market conditions and regulatory environments.

Solidifying Financial Strengths

Strengthening the economics of green projects involves using advanced financial modeling, leveraging diverse funding sources, understanding life cycle financial requirements, and incorporating risk mitigation strategies.

Many companies and investors are still learning how to adequately quantify financial risk and the high degree of uncertainty along the project life cycle—such as regulatory changes, market developments, and technology costs. Improving risk assessment capabilities throughout the project life cycle requires a comprehensive approach, including a fair assessment of risks associated with alternatively investing in traditional projects. This strategy entails collaborating across the value chain, working with regulators, and adopting new contracting models. Companies also need to build capabilities in finance engineering, incorporating new ownership structures and financing instruments to address large green projects’ complex risk profiles. Such capabilities will be new for many CFOs of energy and industrial goods companies.

One primary strategy involves using advanced financial-modeling techniques to develop robust business cases. Probabilistic business case modeling, for instance, allows for the assessment of various scenarios and uncertainties, providing a comprehensive financial outlook. This approach is essential for evaluating strategic combinations of grants, debts, and equity to finance different project phases effectively.

Understanding the financial requirements across the project life cycle—including developmental, capital, and operational expenditures—is essential. This comprehensive knowledge helps in identifying cost drivers and assessing a project’s financial capability. For instance, CCUS projects often require substantial capital for infrastructure and integration, which can be addressed through strategic financial planning and collaborations with experienced engineering and technical partners.

Incorporating sensitivity analyses and risk-sharing mechanisms into the financial model can support efforts to mitigate the risks of capex overruns. Mitigation involves maintaining sufficient liquidity to cover potential overruns and diversifying funding sources and instruments. In addition to embedding robust sensitivity analyses into financial forecasts, developers can collaborate with technical partners to streamline processes.

Crafting a tailored financing strategy is another critical component. This entails leveraging a diverse array of funding sources, including grants, equity, debt, and green bonds. By exploring these options, project developers can secure the financial backing needed to progress through different stages.

An effective financing strategy should include evaluating the strategic mix of funding sources tailored to each project phase and organization structure. For example, using both public and private capital sources and obtaining early-stage financial support from development finance institutions (DFIs) or government funding can sustain project momentum and promote access to expertise. Developers can further secure the necessary capital for project success by transitioning to long-term, lower-cost debt and blended finance instruments as well as leveraging operational cash flows to attract funding from asset managers and corporate investors.

Engaging with DFIs and using public-private partnerships can also help in accessing additional funds and reducing financial risks. For example, projects can benefit from government funding intended to attract private investment. One notable example among North American CCUS projects is the Alberta Carbon Trunk Line in Canada. This initiative includes a 240-kilometer pipeline that transports CO2 from industrial emitters to aging oil fields for enhanced oil recovery and permanent storage. The project received substantial public funding, including CA$495 million from the Alberta government and support from the Canadian federal government. The financing covered the project’s construction and operational costs, thereby attracting further private investment and facilitating its development.

Establishing the Enablers

The enablers of project success include policy advocacy, comprehensive ecosystem partnerships, strategic engagements, and governance. These actions and mechanisms ensure that projects have the required infrastructure, funding, regulatory backing, and management processes.

Engaging in policy advocacy to foster a supportive regulatory environment is a critical step. By working with government agencies, industry associations, and other stakeholders, developers can shape favorable policies and secure incentives. For example, green cement projects must navigate a complex regulatory landscape, including obtaining government support for CCUS projects. Active participation in policy discussions can help to shape industry standards and secure the necessary subsidies and grants. A dedicated team for government engagement can streamline the application process for funding and ensure timely compliance with regulatory requirements.

Forming comprehensive ecosystem partnerships is key to reducing the risks of green projects. These collaborations provide access to capabilities and funding that facilitate the development of necessary infrastructure and address project challenges. In the green cement sector, for example, investing in partnerships for the research and development of new clinker substitutes can address long-term supply problems.

Forming comprehensive ecosystem partnerships is key to reducing the risks of green projects.

In the PtX sector, the Hyphen Hydrogen Energy project in Namibia exemplifies the importance of ecosystem partnerships. This project is a collaboration among the Namibian government, international investors, and technology providers. It aims to produce green hydrogen for both local use and export to Europe. By ensuring access to renewable-energy sources and infrastructure, the cooperative effort reduces project risks and attracts significant private investment.

The steel industry also highlights the value of public-private partnerships. For example, the Stegra project discussed earlier involves collaboration among private investors, technology providers, and the Swedish government. The project benefits from technological expertise from industry leaders as well as government grants and subsidies, ensuring financial viability and operational efficiency.

A well-defined engagement strategy based on a thorough analysis of project requirements and potential gaps is crucial. Early access to strategic assets and capabilities can significantly decrease risks. This includes securing the necessary land, infrastructure, and technology early in the project life cycle. Establishing clear objectives and criteria for collaborations ensures that these engagements are strategically focused and create benefits. For example, in green steel projects, forming joint ventures and partnerships can help gain access to critical technologies and supply chains, promoting projects’ competitiveness and adherence to schedules.

Finally, effective governance models are essential to advance large green projects, because traditional processes and stage gates are often insufficient to address the complexity of these undertakings. Establishing an activist project management office can provide dynamic governance, enabling rapid decision making and adaptive management. An activist approach includes quantitative risk assessments, agile testing, and iterative solution development to respond quickly to emerging challenges.

By fostering a proactive governance structure, developers can better align their projects with evolving regulatory requirements, integrate new technologies efficiently, and maintain the flexibility needed to navigate the uncertainties of large-scale green initiatives. This comprehensive governance model not only enhances project execution but also builds confidence among stakeholders and investors.

To reduce the risks of large green projects and accelerate the path to the final investment decision, developers cannot rely on the tried-and-tested methods used in traditional large capital projects. Instead, they must comprehensively rethink their approach to project governance, incorporating new capabilities and tools. In recent years, industry leaders have demonstrated the winning practices and change management techniques we have described. Successful developers will collaboratively deploy this fresh approach to enhance the overall viability and sustainability of their large green projects.

The authors thank Maria Enderiz, Saurabh Harnathka, Adam Houmour, Radi Ivanova, Catarina Novais, Pei Shan Phung, and Edward Zaayman for their contributions to this article.