Over the past decade, expectations that vendors such as Infor, Microsoft, Oracle, and SAP will end support for their traditional enterprise resource planning (ERP) solutions have been slowly pushing companies to adopt next-generation ERP. But the COVID-19 pandemic will accelerate this migration as digitalization and new ways of working become more critical to business. Indeed, it will be virtually impossible to use traditional ERP to manage the anticipated huge growth in e-commerce and the need for flexibility and speed.

The decisions that companies make today about their ERP systems will set their trajectory for years to come in terms of operational flexibility and resilience. As companies manage the transition to next-generation ERP with digital solutions and cloud features, they must mitigate risks by first addressing their most urgent business challenges and then preparing for a full transformation and a smooth transition of core ERP functionalities.

Critical Business Challenges

The deficiencies of traditional ERP landscapes are all too well known. These platforms contain a vast number of ERP applications with limited integration and interoperability. Heavy customization over time has increased ERP complexity and slowed deployment speeds. Moreover, business insights are difficult to tease out of the data. And integrating new acquisitions is enormously complex.

Despite these shortcomings, the size and pain of a move away from current landscapes have kept the status quo in place at many companies. But now several of the business challenges raised by COVID-19 are tipping the scales toward speedier adoption of next-generation ERP systems. Companies are particularly focused on the following:

- Digital Supply Chains and Smart Manufacturing. Companies need real-time visibility to better manage supply chains. This will allow them, for example, to incorporate weather patterns, port delays, and supplier issues into their decisions—and to course correct in real time. Because of social distancing requirements, they also need to run manufacturing operations and supply chains with fewer workers.

- Digital Finance, Procurement, and HR Functions. Companies need advanced automation that relies on fewer but more qualified workers and workers who can operate from their homes.

- Consumer and Go-to-Market Trends. Companies need to cope with an explosion of consumer data as consumption patterns change. They need to build the scale necessary to ship smaller quantities of goods to more and more residential addresses—and be able to handle a surge in returns.

- Open, Collaborative Ecosystems. Companies need to collaborate digitally with existing suppliers, as in working remotely with fashion retailers, for example, to forecast demand for the next summer collection, or in codesigning new products in “design-to-order” businesses. And they need to replace offshore vendors that have been cut off from transportation.

Next-generation ERP platforms can help companies address all these business challenges. They give companies real-time transparency with respect to sales, inventory, production, and financials. Powerful data-driven analytics enables more agile decisions, such as adjustments to the supply chain to improve resilience. Robust e-commerce capabilities help companies better engage with online customers before and after a sale. And a lean ERP core and "cloud first" approach increase deployment speed.

Three ERP Time Horizons

As companies consider their ERP strategy, they need to frame it with three different time horizons in mind. First comes “the now”—the immediate priorities in the midst of the pandemic. These include protecting people and ensuring business continuity. COVID-19 will force many companies with diminished revenues to pause or slow down their ERP migrations in 2020. But when pausing it is important to pick a good stopping point to revalidate the business case in the face of the new reality and eventually restart the implementation. Companies should take the time now to refine their ERP strategies so they are ready to launch ahead of the pack.

Companies also need to frame a near-term ERP strategy that prepares them for the recovery. The near-term moves are mostly tactical improvements that allow a company to operate better in the current landscape by tackling certain challenges head on. The imperatives include the following:

- Identify opportunities to reduce costs. For example, reduce total cost of ownership by rationalizing ERP apps, and look for opportunities to renegotiate ERP licensing agreements.

- Create more flexible supply chains. Use external data to improve supply and demand forecasting in light of COVID-19, and broaden the supplier ecosystem for resilience. Also, reconfigure warehouses and warehouse management systems so it is possible to ship individual parcels as well as bulk pallets.

- Enable remote working and digital collaboration. Give employees the appropriate remote-working and digital-collaboration tools, ensure that they adhere to the latest cyber/IT security standards, leverage rule-based workflow automation, simplify system touch points to propagate a lean architecture and increase the quality of data entry, and create virtual desktops and mobile front-end apps to facilitate remote work practices.

- Focus on future-oriented platforms. Document the business benefits across different modules, so that requirements are clearer and future design work is easier. Leverage tools for assessing technical debt (the costs of the additional rework necessary in future upgrades).

- Look to acquire ERP talent. Big system integrators are expected to freeze hiring or even cut back as their outlooks worsen. This creates opportunities to pick up top talent and build internal ERP capabilities.

Finally, companies need to frame a long-term ERP strategy to win in the new environment that emerges after the pandemic. Think about ways to cut out the complexity and rigidity that have developed in connection with highly customized traditional ERP systems. By embracing enhanced digital collaboration, simplified business processes, and real-time insight through the use of standardized reports, tables, and program configurations, a company can use the modular architecture of next-generation ERP systems to increase speed, quality, and productivity.

Migration Considerations

Putting an ERP migration on hold in the current environment is understandable, but a company should not wait too long if it believes the transition is vital for the business. There is pent up need to make the switch, both because vendor support will end later this decade and because the pandemic has brought new focus to digitalization. As a result, many companies might try to transform or migrate at the same time, which would create a resource crunch, drive up implementation costs, and elongate the implementation timeline.

That said, any ERP migration will tax resources. Business leaders need to keep four key considerations in mind to ensure success.

Organizational Commitment. As with so many enterprise-wide initiatives, success depends on strong buy-in from senior leaders and other key stakeholders. They need a clear vision of how the ERP-based transformation will improve the business, and they must lend continuous, visible support for the migration. Leaders and the business process owners must align on goals and agree on the progress metrics. It is also important to set guidelines for how the ERP implementation team and the business process owners will engage throughout the initiative, from design to go-live.

Modular Design. Ideally, the company will keep the new ERP core as close to standard functionality as possible. This allows the company to leverage modular, best-in-class innovations—on top of or outside of the ERP systems—for faster attainment of business benefits. A lean, modular ERP architecture is API-based, cloud-ready, and agile.

Planning and Execution Rigor. About 60% of ERP programs suffer delays, a major reason being that system integrators sometimes take a cookie-cutter approach to program management, using point-in-time information. What’s needed instead is a forward-looking, metrics-driven, and objective approach to program execution. The planning steps should include defining the change management process (for example, the escalation/resolution processes for change requests); creating governance mechanisms (compliance and progress tracking, for instance); identifying all cross-functional interdependencies; developing system testing scenarios before go-live (for example, by factoring in all process variations, exception scenarios, and edge cases); uncovering potential risks; and conducting a bottom-up planning exercise to build a robust implementation plan.

The Right Partner. Robust due diligence is critical when choosing a system integrator. Align with the partner on targets, metrics, and advanced-warning mechanisms that can alert the team if the implementation starts going off track. Build in-house ERP skills by training internal staff and selectively hiring experts.

Next-Generation ERP in Action

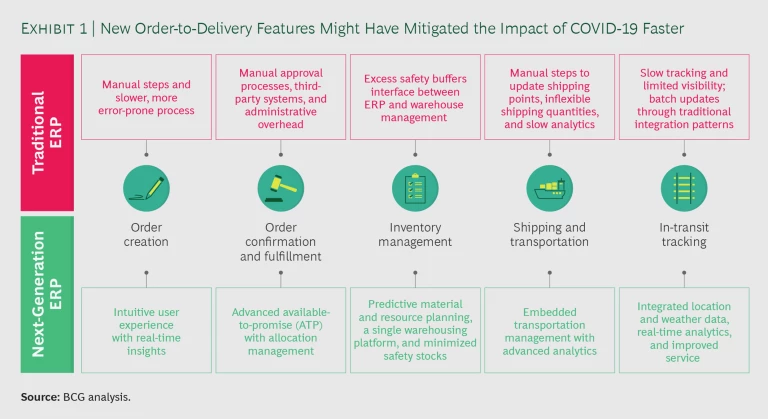

To get a better idea of how the new digital functionality in next-generation ERP could help mitigate COVID-19 issues, we took a close look at two business functions. In the first case, we looked at order-to-delivery management. (See Exhibit 1.)

In traditional ERP supply planning, poor visibility into the order management system means that companies often resolve order fulfillment issues slowly, which can delay delivery. Next-generation ERP can monitor the fulfillment status of all sales orders in real time and use a list of key characteristics to prioritize outstanding sales orders. Another challenge relates to rebate processing. In traditional ERP, rebate calculations often depend solely on customer invoices, which necessitates a time-consuming and error-prone process. Next-generation ERP can settle rebates immediately, without manual activities.

Next-generation ERP also offers better support for complex B2B agreements and contractual relationships by bundling product sales with projects, service offerings, subscriptions, and other information into one master agreement. The new systems also embed better support for international trade (which reduces financial risk) and can generate reliable customer delivery dates (for example, by using demand characteristics to allocate short supply), which improves customer satisfaction and avoids revenue loss.

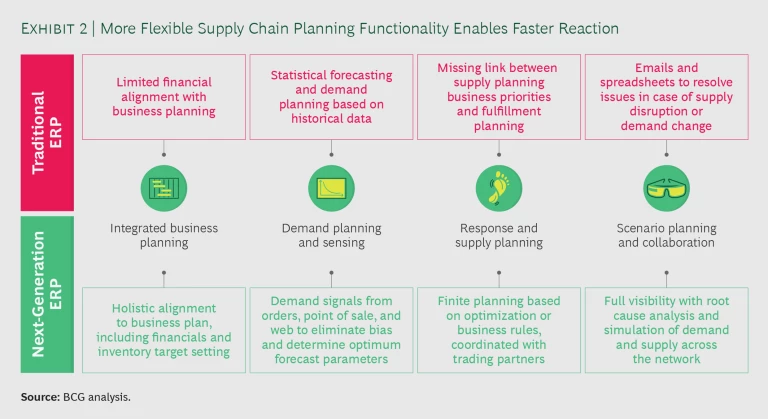

In another case, we looked at how next-generation ERP could improve supply planning. (See Exhibit 2.) In traditional ERP, planning features are basic, with little ability to predict short-term demand. Next-generation ERP, by comparison, offers a real-time, omnichannel order management platform that identifies demand changes without lengthy batch processing.

Other challenges with traditional ERP include fragmented and manually intensive material requirement planning (MRP) processes, difficulty setting inventory targets across the supply chain, and overnight waits for inventory updates. Next-generation ERP addresses all these issues by providing a single MRP process (with a real-time dashboard) and live inventory management that enables simultaneous material movements.

A successful migration to next-generation ERP requires leaders who are committed to this complex transition because they firmly understand the specific benefits and the overall value to the business. When we exit the COVID-19 crisis, leaders who are ready to launch or resume their migration will be in a position to boost their operations’ flexibility and resilience. More than ever, these characteristics will be crucial to success.