Combining distributed and additive manufacturing mitigates supply chain risks by enabling fully digital interactions, better economics for producing small quantities, and flexible capacity.

Distributed manufacturing and additive manufacturing (also known as 3D printing) can be a powerful combination for solving supply chain challenges. Leading companies are managing supply risks by distributing production geographically, over time, or across the value chain. Unfortunately, this approach often faces limitations—including high costs, low asset utilization, long setup times, and stringent regulatory requirements.

Additive manufacturing offers a solution to the challenges of distributed manufacturing by enabling local and highly flexible production of small quantities. For many use cases, additive manufacturing systems and processes are now technologically ready for small-series production. Applying 3D printing in distributed manufacturing will be most beneficial for producing high-value parts, such as those used in the aerospace and medical-technology industries, or low-volume replacement parts. These are among the transformative technology applications that constitute Industry 4.0 .

In 2022, BCG undertook a study, in collaboration with RWTH Aachen University and the ACAM Aachen Center for Additive Manufacturing, to capture insights into how the application of 3D printing in distributed manufacturing adds value and what the prerequisites are for successful use cases. The study included interviews with a panel of approximately 15 leading experts in business and academia, from a variety of countries.

Supply Chain Challenges Persist

Global supply chains are ubiquitous in many industries as companies seek to optimize sourcing costs. But frequent interruptions have jeopardized timely fulfillment and deliveries. Numerous recent events have demonstrated the fragility of supply chains, including the COVID-19 pandemic, the war in Ukraine, economic sanctions, politically motivated tariffs, and natural disasters.

And many difficulties continue. In early 2022, for example, COVID-19 restrictions in China shut down factories, logistics operations, and ports. Vital components for global producers, which normally move within hours, piled up. These included not only electronics but also low-value parts that could easily be printed. Because Chinese manufacturers are the sole sources of some components, few suppliers could serve as short-term replacements and the available alternatives were quickly overbooked.

Often, 3D printing is the most cost-competitive technology for low-volume production.

Sustainability initiatives present additional supply challenges. For example, EU regulators have proposed legislation that would encourage consumers to repair older products or purchase more secondhand and refurbished products. Such initiatives would require producers to significantly expand their spare-part portfolios. In many cases, producing these typically low-volume series parts is only possible using on-demand manufacturing that draws on a digital inventory of designs. Often, 3D printing is the most cost-competitive technology for such low-volume production.

Distributed Concepts Hold Promise but Have Limitations

Companies have sought ways to avert the disruptions caused by delayed deliveries or avoid the higher costs of using alternative means of transport or sourcing. A solution gaining traction is to redesign supply chains and production networks toward distributed manufacturing.

To mitigate specific supply chain risks, producers can distribute manufacturing in three ways. Companies can apply these dimensions individually or in combination:

- Geographically. Producing the same or similar products at multiple locations, often close to the point of demand.

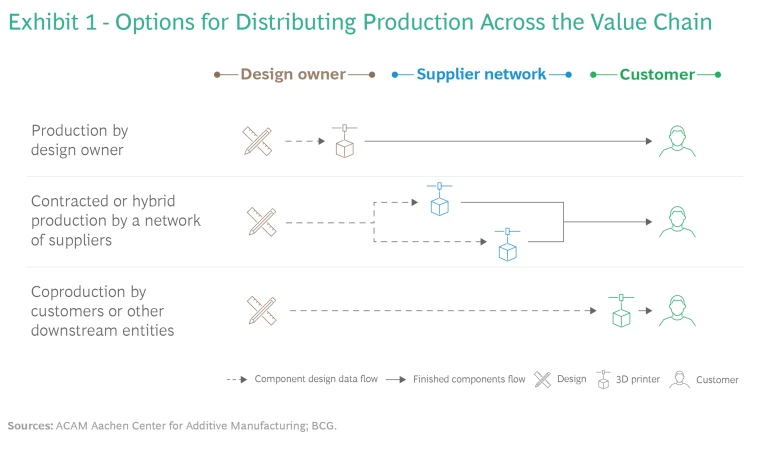

- Across the Value Chain. Distributing production to other entities, such as supplier networks or even customers. (See Exhibit 1.)

- Over Time. Spreading production over time in precise quantities to serve sporadic and hard-to-predict demand. This enables “batch-less” production (one item at a time) for inventory-optimized supply.

The benefits that producers capture from distributed manufacturing generally include at least one of the following:

- Strengthening Operational Resilience. Companies can improve their ability to respond to supply shocks in a variety of ways. For example, shorter lead times allow for faster reactions to supply chain interruptions. Producing precise quantities to meet sporadic and hard-to-predict demand reduces unnecessary inventory while ensuring availability. And establishing numerous sourcing alternatives with respect to locations or suppliers decreases dependencies and increases flexibility.

- Reducing Emissions and Scrap. Distributed manufacturing lessens or even averts the need for long-distance transportation or ad hoc solutions to address disruptions. This cuts supply chain emissions, especially if air freight is decreased or avoided, thereby improving a product’s CO2 footprint. Eliminating long-tail stock, including inventory that is ultimately scrapped, reduces waste. By making spare-part supply economically feasible, distributed manufacturing helps prolong product life cycles.

- Boosting Profits and Generating Revenue. Distributed manufacturing can improve the bottom line by cutting costs for storage and distribution, end-of-life solutions, and tariffs. It also raises cost efficiency by reducing or eliminating minimum order quantities. In addition, companies can capture the revenue upside from new business opportunities. They can provide new services for unsolved customer challenges (for example, making spare-part supply economically feasible) or higher-value services (such as faster spare-part supply).

But distributed manufacturing is not the best option, or even viable, in all cases. A company must be able to sufficiently use its distributed-production capacity—the logistics cost advantages must outweigh the lost benefits of scale. Moreover, production processes should be highly automated. If substantial manual work is required, such as for additional assembly steps, companies risk incurring increased labor costs. In addition, temporal distribution is effective only if processes have short setup times. A company also needs to consider regulatory constraints. If a process is strictly regulated or operators need special qualifications, for example, distributing production is more challenging.

Additive Manufacturing Addresses the Limitations but Has Its Own Constraints

The characteristics of additive manufacturing make it a leading choice for tackling the challenges of distributed production. It enables producers to capture several advantages:

- A Highly Integrated and Digital Process. Additive manufacturing allows fully digital interactions between the producer and the party printing the product. The producer transfers the print file or intellectual property (IP) related to a part’s geometry to the printing provider. The parties have the option of using blockchain for the highest security standards . There is no need for either party to maintain an inventory of tools or semifinished products. Digitized, tool-less processes make it cost-effective to distribute production geographically, while improved IP protection facilitates production across the value chain. The experts we interviewed in our study highlighted the advantages of digitization as important motivations for applying additive manufacturing in distributed production.

- A Competitive Cost at Low Volumes. Batch-less production eliminates the need for minimum order quantities. Producing small quantities on additive-manufacturing systems often has far better economics than using conventional production methods, such as injection molding with high upfront tooling costs. This makes 3D printing suitable to cover demand on a more granular level.

- An Expanding Global Production Network. The growing production network for additive manufacturing, including service bureaus, has made production capacity flexibly available across major regions. The increasing standardization of processes and materials further facilitates the distribution of production.

In pursuing these advantages, companies should be mindful that additive manufacturing is not a panacea. The experts we interviewed highlighted four constraints to using additive manufacturing in industrial applications that are especially relevant to distributed production:

- The lack of standardization, such as for materials and data exchange protocols

- The small number of players that offer qualification and certification of printing equipment for specific industries

- The long processing times owing to slow build rates

- The limited availability or high variability of raw materials

As the technology continues to mature, we expect that these constraints will ease.

Explore the Use Cases

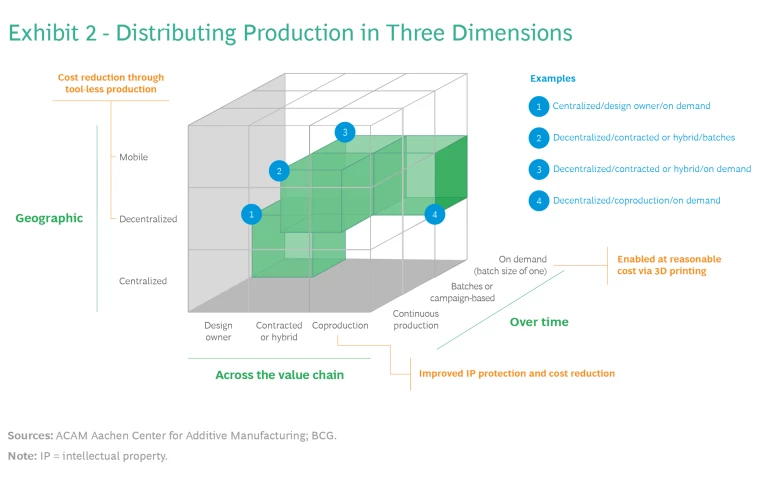

Considering these advantages and constraints, producers need to focus on using additive manufacturing to enable specific applications. Several examples illustrate how leading companies are exploring the opportunities. Exhibit 2 pinpoints these use cases within a cube that encompasses the three dimensions of distributed manufacturing—geographic, across the value chain, and over time.

Centralized/Design Owner/On Demand

During the early days of the COVID-19 pandemic, Danfoss, a maker of heating and cooling products, needed to temporarily shut down because it could not get supplies for injection molding. As a short-term solution to resume operations , the company printed polymer parts. Although 3D printing costs more than conventional manufacturing, the approach allowed Danfoss to deliver products on schedule.

Decentralized/Contracted or Hybrid/Batches

Alstom, a manufacturer of railway equipment, uses the decentralized network of Replique, a 3D printing provider, to produce small batches of parts. Decentralized production minimizes lead times, enabling faster and more cost-effective responses to customer requirements. It also reduces the complexity of procurement and production. Outsourcing allows Alstom to capture these benefits while avoiding the significant investments required for technology and materials. The first serial part printed in this arrangement—a metal doorstopper—was qualified and produced within six weeks at costs that were competitive with those of traditional manufacturing.

Cead produces 3D printing equipment for manufacturing large items used in a variety of industries, including maritime, aerospace, automotive, and leisure. But a small-series producer cannot, by itself, economically use the asset-heavy equipment. To address this challenge, Cead is collaborating with FlexFactory to offer the equipment via a production-as-a-service model in which customers pay per part. The equipment is owned by an external investor, serviced by Cead, located in regional facilities, and shared by multiple customers. This enables decentralized, “local for local” production of small batches close to customers.

Decentralized/Contracted or Hybrid/On Demand

Siena Garden, a provider of garden furniture, offers “eternal” spare parts to customers via 3D printing. Spare parts present a dilemma to many manufacturers. After a manufacturer has stopped making a product, procuring spare parts becomes difficult—even though more customers need them. But maintaining inventories of spare parts is neither economical nor sustainable, as they would need to be scrapped if demand forecasts are inaccurate. To address this issue, Siena Garden stores the design and print parameters for spare parts in Replique’s digital inventory. Parts, such as leg caps, are printed only when customers order them. Even if printed parts cost more than those made using traditional production, customers save money and contribute to sustainability by repairing furniture instead of buying new products.

Decentralized/Coproduction/On Demand

Miele, a producer of vacuum cleaners and other household appliances, wanted to differentiate its offerings through a broad selection of accessories. The company designed several new accessories for 3D printing under the brand “3D4U powered by Miele.” Initially, the company offered free downloadable files that customers could print at home. In a more scalable offering, customers can now buy parts in Miele’s online shop and have them printed via Replique’s network. An order automatically triggers just-in-time printing from the digital inventory, and parts are sent directly to customers in Miele packaging. This inventory-free approach enables Miele to broaden its portfolio of accessories with minimal fixed costs.

Another use of additive manufacturing is for in-office printing of dental appliances, such as dentures or occlusal guards, by practices and clinics. These temporary or intermediate products resolve the patient’s problem quickly—before the final appliance is produced in a dental lab. Patients appreciate the swift and convenient solution, while dentists gain revenue from offering intermediate products.

Identify Economically Viable Use Cases

To capture the benefits, the applications of additive manufacturing need to fulfill two conditions . First, they must be technically feasible with 3D printing technologies —that is, the part must have the required quality and material characteristics. Second, applications must be economically feasible; the manufacturer must realize an attractive profit margin with the printed part.

Focusing on the second condition, producers can assess economic viability by considering the following questions across the three dimensions of distributed manufacturing:

Geographic. Speed and costs are the key considerations:

- Do our products require fast response times?

- Does product fulfillment entail high transportation costs (such as using air freight to shorten delivery times)?

Across the Value Chain. Viability depends on supply risks and the availability of alternatives:

- Do we experience or expect supply shortfalls from specific suppliers?

- Do we rely on only one supplier or a small set of suppliers for certain components?

- Does upstream or downstream production capacity already exist or is it relatively easy to put in place?

- Do our downstream customers or end users have access to printing resources?

Over Time. The predictability, duration, and size of demand affect the economics:

- Do we experience or expect sporadic and hard-to-predict demand?

- Do our products require spare parts over a long life cycle?

- Do customers generally order our products in small quantities or batch sizes?

For all selected use cases, the manufacturing process must comply with regulatory requirements, and as noted, the parts in scope must be technically suitable for additive manufacturing. Equipment use often determines the feasibility of employing additive manufacturing in a distributed approach. Third-party service providers can ensure sufficient machine utilization by bundling demand for low-quantity production from multiple producers.

Producers can combine distributed and additive manufacturing to mitigate rising supply chain risks. The combined approach helps companies promote resilience, sustainability, and value creation. Success requires assessing how additive manufacturing can enable economically viable use cases across the three dimensions of distributed manufacturing. Given the persistence of supply chain challenges, all producers should consider their options for empowering distributed manufacturing with 3D printing.

ACAM Aachen Center for Additive Manufacturing is preparing a report that provides additional insights on the topics covered in this article. The report will be available on its studies webpage .