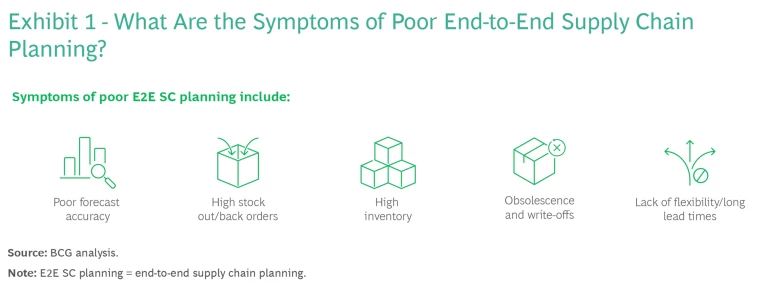

Supply chain challenges continue to be top of mind for business leaders and investors. Turbulence driven by recent disruptions, increasingly complex supply chains, and the advancement of data analytics have accelerated the need for a new approach to end-to-end (E2E) planning. Companies often struggle to match decision-making speed with changing dynamics, which in turn drives demand volatility, impacts supply reliability, and increases the need for collaboration across the value chain. (See Exhibit 1.)

Five Questions to Ask

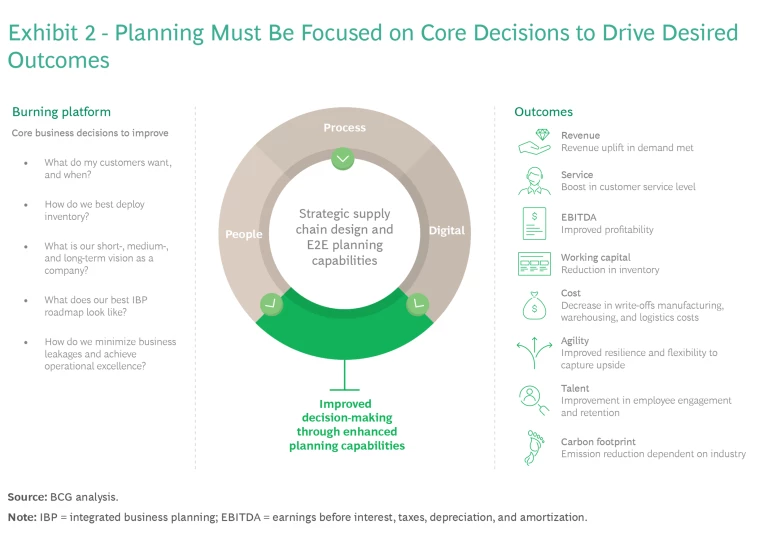

Our decision-led approach to end-to-end planning transformation begins and ends with a value-centric focus on key decisions to drive business outcomes. In practice, this means companies must answer five key questions:

- What are the key decisions for our business? Among the decisions to consider are optimized product portfolio, make vs buy, location of factories and warehouses, and deployment of inventory to meet segmented service levels.

- What are our main value drivers and impacts? These include improved customer service (reduced out of stocks) and satisfaction, increased revenue and margin optimization, reduction in waste and emissions, and greater resilience and agility.

- What works well when we make decisions and get to great outcomes? Conversely, when we made bad decisions, what went wrong? Pay attention to robust data accuracy and universality, high forecast accuracy, production effectively loaded across the network to optimize constrained assets while minimizing landed cost to customer, and seamless communication across key decision-makers.

- How can we ensure that we do the right things across process, people, and digital? This means anchoring solutions on “how the work gets done” to address gaps, using modern forecasting and optimization techniques, and leveraging experience of planners when building decision-support tools and expert systems.

- How do we absorb and scale these new ways of working? Take steps to align KPIs with business objectives, scale, and enterprise-wide adoption; manage the change and build people capability; and establish a feedback loop to continuously improve.

Best-in-class companies optimize decision-making by transforming “how the work gets done” through the convergence of process, people, and digital. (See Exhibit 2.)

A Success Story

For companies to succeed, decision-led planning must become the organization’s drumbeat—optimizing decisions across the supply chain and orchestrating activities across functions (finance, R&D, sales and marketing, operations). Technology platforms have enabled better transparency and connectivity across functions and locations; however, these enhancements are often approached as a systems transformation that is too seldom viewed as a business transformation (which needs to yield financial benefits). At the same time, digital and AI-driven algorithms hold amazing promise when it comes to driving insight to patterns and enabling faster optimization of plans but can be overwhelming in terms of the need for talent.

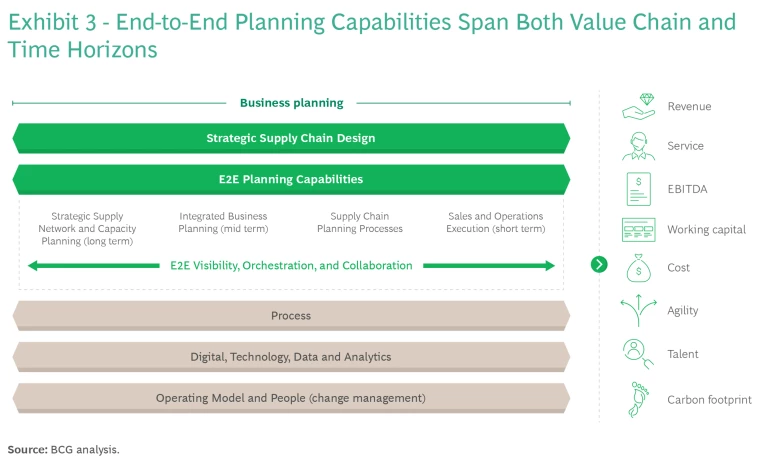

Building excellence in E2E planning is a journey; with higher maturity comes greater reward. In our experience, companies tend to have different starting points based on their specific industry, competitive positioning, and supply chain setup. We typically work with businesses to build their supply chain capabilities ensuring alignment across the value chain and different planning horizons. (See Exhibit 3). The critical question is: “What is needed to enable a sequence of great decisions?”

As an example, we helped a global consumer packaged goods player which had high complexity in their portfolio and supply chain. They needed a decision-led and value-driven approach to improving customize service levels and simultaneously drive cost improvements through better planning and inventory optimization. We undertook a demand planning and an integrated business planning (IBP) transformation, which encompassed:

- Redesign of the demand planning and customer planning processes across markets to drive better adherence and cross functional alignment.

- Building and integrating to a single platform with advanced, machine-learning based forecast—this platform incorporated new demand signals and scenario modeling within their existing IT infrastructure and enabled transparency and comparison across markets/regions.

- Deploying people-focused training tailored to different user personas (for example, demand planner vs sales planner vs supply planner) and concentrated on making better planning decisions as part of how they did their job.

- Running “side-by-side” IBP cycles to train the users on the new ways of working in “real-time parallel runs” to the current outdated sales and operations planning process to showcase the differences and gradually cut over into the new process/ways of working.

This resulted in an estimated 15%–30% inventory reduction, 2%–3% logistics and planning cost savings, and an increased revenue 2%–4% across different markets/categories for our client.

With the inevitability of future challenges and disruptions, supply chain planning will remain a critical capability for companies wanting to improve their competitive advantage and build resilience. The following core principles are key:

- Determine the starting point and priorities and establish common goals to evaluate progress (for example, customer service levels).

- Estimate the profit and loss impact; start with the decisions which can deliver impact in the first three to six months; build momentum and prioritize a waved rollout of new capabilities to fund the journey.

- Create predictable and repeatable planning processes that engage stakeholders in informed and aligned decisions.

- Empower leaders and teams to define the path forward and drive ownership.

- Enhance processes and people capability with digital tools to change how the work gets done.

Organizations that embrace these principles as part of a disciplined and structured approach stand to succeed.

The authors thank BCG colleagues Dustin Burke, Bitan Datta, Andres Garro, and Marcel Sieke for their key contributions to this article.