Because rail is one of the cleanest modes of mass transport, demand is set to soar over the coming decades. In Europe, rail is projected to account for one-third of freight transportation by 2030 (up from 18% today) and 16% of all passenger trips (compared with 9% today), according to Germany’s rail industry association. In the US, about one-third of freight ton-miles are by rail—though this proportion is likely to increase as greater use is made of the rail network.

Following years of underinvestment, however, most national rail networks are already overused—meaning that the demand for existing infrastructure capacity, either for carrying trains or for maintenance work, exceeds supply. The result: poor punctuality and reduced customer satisfaction. For many train operators, such issues come on top of the growing challenge of securing sufficient rolling-stock capacity.

Managers of national, mainly government-owned rail infrastructure are pushing to rectify the problem of overuse by introducing programs that will expand and modernize rail networks, enabling rail infrastructure managers to improve services and achieve green-mobility goals. For example, the US has set aside $100 billion of funding for rail improvement projects through 2026. In addition, by upgrading the rail infrastructure, rail agencies can prepare networks for new requirements, such as the use of green hydrogen to power trains.

But building new tracks and stations can take decades and is fraught with challenges, especially those related to keeping projects on schedule and on budget. Flagship railway projects in London, Munich, Mumbai, and California have all struggled with significant cost overruns and delays in recent years. And upgrade and construction activities can put large sections of the network out of commission, compounding capacity problems.

Rail infrastructure managers need to get more out of their existing assets in the near term by using them more effectively.

What’s the answer? While longer-term solutions are important, we believe that rail infrastructure managers need to get more out of their existing assets in the near term by using them more effectively. Among the actions they should consider are making capacity a primary driver of operational decisions, developing a dedicated capacity management function, and introducing modern digital systems.

Three Routes for Solving Infrastructure Capacity Problems

Historically, the rail industry has not suffered from a lack of infrastructure capacity. For a long time, national rail networks were large and relatively underused. The mass closure of railway lines and stations, as occurred in the UK in the 1960s and Germany from the mid-1990s to 2012, reduced the size of networks. But as countries turn to rail to help achieve their climate goals , demand has picked up again, and the pressures on rail networks have mounted.

Capacity shortages prevent networks from operating as effectively as they could, creating serious knock-on consequences for users. Poor punctuality by train operators and maintenance work that runs overtime have a negative impact on other rail services. Capacity-induced problems are particularly severe in countries where different types of rail activity—such as long distance, regional, and freight operations—share the same tracks and in countries with high levels of rail usage.

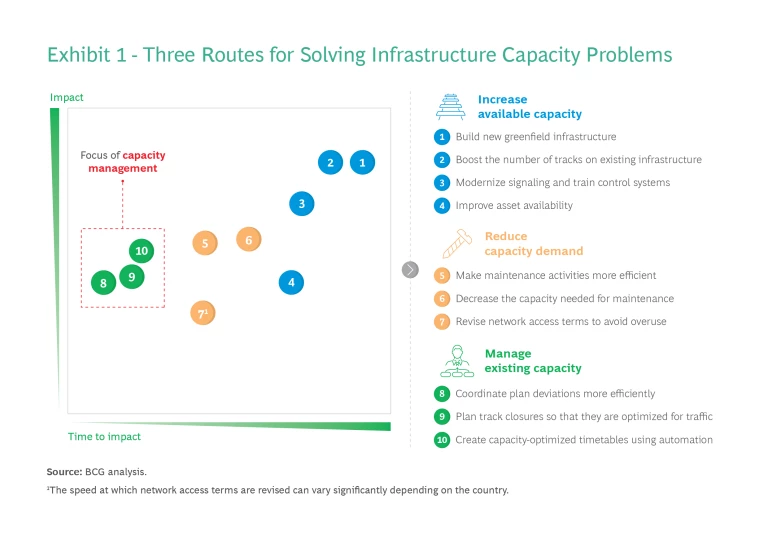

Rail infrastructure managers have three ways to solve infrastructure capacity issues. (See Exhibit 1.)

Increase available capacity. Rail infrastructure managers can add and upgrade tracks or modernize signaling and communication systems to expand available capacity and enable operators to use the infrastructure more efficiently. By investing in newer and better-quality assets, infrastructure managers can also improve the availability of infrastructure and reduce the need for maintenance.

More than $220 billion is spent annually on global rail infrastructure investments, according to the Organisation for Economic Co-operation and Development. In addition to the US investment noted earlier, the German government plans to invest $190 billion by 2030 in its national rail network, India is spending $720 billion, and Canada $80 billion. While these investments will form part of the solution for capacity shortages in the long term, in the near future the construction activities they involve will require capacity as most of the work will be carried out on the existing infrastructure.

Reduce capacity demand. Rail infrastructure managers can take steps to decrease demand. Curbing the number of trains that use the network is not an option, as it is diametrically opposed to the shift toward rail as a cleaner, greener transportation mode. But by making maintenance and construction activities more efficient, infrastructure managers can cut the time needed for accessing the rail infrastructure. For example, using remote asset monitoring for condition-based or predictive maintenance can lessen the need for physical inspections and last-minute maintenance work.

In some countries, rail infrastructure managers handle maintenance work in-house; in other nations, they outsource these activities to third-party contractors. Either way, in the majority of markets, infrastructure managers are responsible for the planning and project management phases. They can achieve significant efficiency gains by ensuring that work streams for different parts of the network are carried out in parallel to minimize track closures, by requiring contractors to use shift arrangements that include around-the-clock work, or by stipulating that the work is performed when fewer trains are operating, such as at night.

Manage existing capacity. Rail infrastructure managers can develop tools to manage existing infrastructure capacity better—for example, by planning track closures so that they fit in with operators’ proposed schedules. The benefit of this approach is that it has a much faster impact than the other two levers. Building new physical infrastructure can take ten years or more, whereas—with the right capabilities—infrastructure managers can optimize capacity within a matter of hours. As a result, we believe that capacity management will be an essential measure as more and more goods and passengers are carried by rail over the next ten years. Because of the important role capacity management will play in the future, we focus on capacity management pain points and levers below.

Key Pain Points in Capacity Management

Capacity management isn’t just about ensuring that passenger and freight operations run smoothly today. By making decisions about whether to assign a section of track for use by a train operator or for an upgrade that will support greater capacity, capacity management departments determine the future shape of railway networks.

Capacity management isn’t just about ensuring that passenger and freight operations run smoothly today—capacity management departments can determine the future shape of railway networks.

Good capacity management starts with timetabling: through schedules, a rail infrastructure manager sets out the use of infrastructure capacity on any given day. The creation of an initial timetabling concept, which establishes the infrastructure manager’s high-level goals for the network on the basis of anticipated demand and usually occurs several years before the timetable goes live, can have a big early-stage impact on the effectiveness of capacity management efforts.

But we’ve found that most rail infrastructure managers are either held back by legacy practices or don’t have the necessary capabilities, preventing them from delivering strong capacity management. Here are six typical shortcomings:

- In many countries, rail infrastructure managers don’t include good capacity utilization in their core goals. Instead, they make decisions with the aim of achieving financial targets. As a result, infrastructure managers lack the means to improve capacity utilization because this requires an in-depth understanding of capacity chokepoints.

- Some rail infrastructure managers don’t have clearly defined priorities when making timetabling decisions or an integrated view on how to meet the needs of rail passengers and freight players. As a result, it’s left to staff to decide whether to prioritize capacity (for example, by moving planned construction work to the nighttime or weekend when fewer trains are running) or profitability (by allowing construction companies to carry out work during the day, thus avoiding additional contractor fees).

- Many rail infrastructure managers lack the software-based simulation capabilities needed to accurately predict the demand for infrastructure capacity from train operators and maintenance staff or the impact of track closures on planned services. Without this information, it’s harder for infrastructure managers to persuade operators to move a service to another time or operate a different route.

- Automated timetabling systems can make decisions that optimize the use of infrastructure capacity. Unfortunately, many rail infrastructure managers don’t have these systems. Instead, staff still create timetables manually. This approach is time consuming and leads to errors. In addition, shifts in ridership patterns in some markets, such as from on-peak to off-peak travel, can add further complications to manual timetable generation. It also means that staff may try to fit more trains into the timetable than makes sense from a capacity perspective, resulting in logjams.

- In many countries, staff make poor decisions about key timetabling parameters because they rely on outdated or inaccurate information. For example, staff often allocate too much or too little time for trains to stop at stations (or plan on the basis of an inaccurate maximum train speed). Over the course of a day, a few extra seconds of stopping time per station can accumulate into a serious constraint on the available infrastructure capacity.

- Maintenance and building contractors are slow to share information with the rail infrastructure manager about proposed work or might change their plans at the last minute. This results in staff needing to update their schedules—often just weeks or days before the schedule goes live—undermining efforts to use infrastructure capacity efficiently. The late changes can also mean that operators struggle to find drivers, are forced to cancel trains, or give passengers inaccurate information.

Levers for Better Capacity Management

In our experience working with leading rail infrastructure managers worldwide, a combination of organizational, process, and IT changes is needed for good capacity management. While digitization is an essential element because it leads to greater transparency and automation, infrastructure managers often focus too much on a single, large, transformational IT project and neglect nondigital actions, such as making capacity utilization a primary driver of operational decisions.

We’ve identified some key levers that will help rail infrastructure managers create more effective capacity management.

Shift from capacity administrators to capacity managers. It’s critical that rail infrastructure managers make capacity utilization an essential metric when formulating operational and resource decisions. Infrastructure managers should teach staff to think of infrastructure capacity as an important and scarce resource—and to alter their behavior accordingly. Staff need to change their mindset and start actively managing capacity and using it more effectively. As part of this push, infrastructure managers should make data about current capacity availability and utilization, as well as about the impact of timetabling decisions on capacity, more readily available to staff. Infrastructure managers can do this by using easy-to-understand reporting tools such as dashboards, improving internal communications, and investing in new software systems.

Rail infrastructure managers should also set up a dedicated capacity management function. This should sit alongside the timetabling department, or be integrated within it, but have a more cross-functional role. For example, to make effective decisions, the function would need detailed inputs about operations, maintenance, and construction activities from the relevant departments. It would also require a robust mandate to decide how capacity should be used (whether for carrying trains or completing construction and maintenance work) at any given time to optimize the network not just for today’s traffic but for future needs.

Develop customer-centric processes. To avoid last-minute disruptions to the network, rail infrastructure managers should forge close links with rail passenger and freight operators. By discussing any proposed track closures early, all parties can understand the impact on their customers better. This also gives infrastructure managers time to adapt their plans to be as accommodating as possible and allows operators to make any necessary changes to their services well in advance. In the event that network disruptions are inevitable (for example, with large-scale building work), infrastructure managers should consider creating timetable templates. These are ready-made scheduling solutions, based on different demand scenarios, that are already optimized for capacity and are prealigned with customer requirements, enabling infrastructure managers to deliver a high-quality operating plan quickly.

Build modern IT systems. To benefit from digitization, rail infrastructure managers should invest in a digital transport management system (TMS) that enables them to manage infrastructure capacity in an integrated way—taking into account the needs of all users—across all time horizons. As part of their TMS, infrastructure managers should build digital capabilities that automatically construct timetables while optimizing capacity usage. These capabilities will need to be scalable to cope with the growing demands on the network.

As more and more countries turn to rail-based transportation to achieve their climate goals, demand for rail infrastructure capacity looks set to soar—far outpacing the ability of investment programs to create additional supply. As a result, rail infrastructure managers need to sharpen their existing tools and make use of new ones, such as modern digital capabilities, to avoid the threat of network congestion. Building a complete set of measures for managing capacity utilization effectively will take several years. But it’s imperative that infrastructure managers start now. By doing so, they can ensure that networks meet operators’ needs and support the building work that is essential for the future of rail transportation.