Supply chains play a leading role in enterprise growth . They are the engine of a virtuous cycle, driving customer satisfaction and, ultimately, higher revenue. But they are often vulnerable to the demand and supply uncertainties of the global landscape.

To increase resilience and improve performance, many companies have set out to transform their supply chains. Like builders constructing a complex house, however, they often must contend with the challenges of coordinating multiple teams, meeting ever-increasing demands for digitization, and adhering to accelerated timelines. As a result, their ambitious transformation initiatives fall short of expectations.

So how can companies ensure that every team involved in a

supply chain transformation

works in concert? We propose an innovative approach that allows companies to align their disparate supply chain elements with their broader business and commercial aspirations.

Supply Chains Are Essential but Fragile

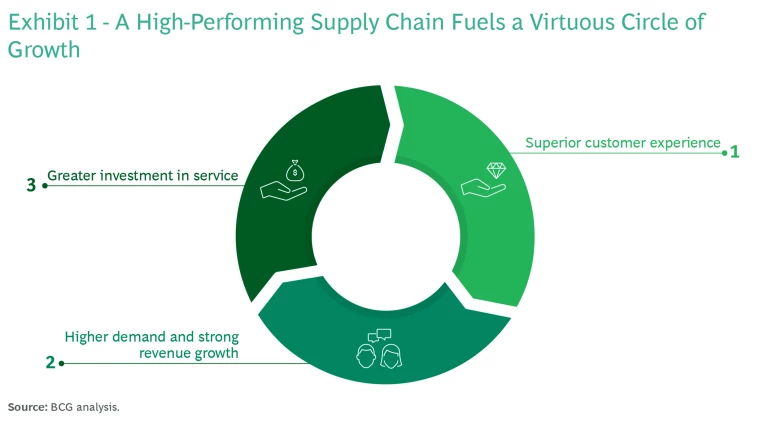

By ensuring that the right products are available when and where they are needed, a high-performing supply chain enables exceptional customer experiences and fuels a virtuous cycle of growth. (See Exhibit 1.) The cycle starts with superior customer service, which drives demand and traffic. This, in turn, creates growth in revenue and margins. Ultimately, it provides the company with healthy coffers with which to further invest in capabilities such as talent, automation, and the data foundation that will improve customer service.

However, supply chains remain vulnerable to uncertainty and complexity arising from geopolitical volatility, macroeconomic challenges, climate change, technology disruptions, and changing consumer expectations. The pandemic-related supply chain shocks were not a temporary aberration but rather an especially acute illustration of supply chain fragility that will continue to threaten revenue growth.

In 2023, for example, despite an inflation rate exceeding 6%, retail sales continued to grow. The resulting strain on transportation and warehousing capacity drove higher costs—average freight costs in January 2023, for instance, were double those of four years earlier. Geopolitical factors, such as the war in Ukraine, have also intensified pressure on supply chains. Given this challenging environment, the need to strengthen supply chains has never been more pressing.

Transforming Supply Chains Is a Lot Like Building a House

Recognizing the urgency, many companies have launched end-to-end transformation initiatives to boost resilience and enhance their supply chain performance. But most of these efforts fail to meet expectations. In consumer sectors, less than 30% of large-scale supply chain transformations achieve their goals on time and within budget.

To grasp why supply chain transformations typically fall short, consider the building of a house. Homebuilders may start with a clear vision and a high-level blueprint. And they may employ the best architects, construction managers, masonry workers, plumbers, roofers, and electricians. But then the challenges begin. Although all the contractors may excel in their fields and follow the blueprint, they often lack the detailed information necessary to agree on key interfaces, dependencies, and design assumptions. Consequently, early prototypes may exhibit problems like rooms not connecting seamlessly with the roof or electrical wires laid in incorrect locations.

To improve coordination, homebuilders can hire a general contractor to orchestrate the various contractors. While this is a positive step, new problems arise: seamless integration is hampered by differing assumptions among the contractors, by the need to incorporate digital technologies for a “smart” house, and by the pressure to complete work within a reasonable timeframe.

Similar challenges occur when companies attempt to transform their supply chains. Many companies start with a piecemeal approach, addressing only specific aspects of the supply chain. Consider the example of an integrated business planning team establishing an AI-enabled multi-echelon revenue forecast for the end-to-end supply chain. Capturing the promised value from this initiative requires significant cross-functional coordination. The supply chain technology team must provide technological and data support, while the distribution and warehousing team must convert the new revenue forecast into daily labor, inventory, and trucking forecasts.

Many companies start with a piecemeal approach, addressing only specific aspects of the supply chain.

To remedy the shortcomings of a fragmented approach, the company may embark on an end-to-end transformation. It implements AI-enabled forecasting, for example, as one aspect of a broader transformation that also includes redefining the underlying processes and data foundations to ensure that an improved demand signal translates into better daily or weekly order fulfillment, replenishment, and inventory placement decisions across warehouses and store locations. While this holistic approach has the right level of ambition, it is challenging for three main reasons:

- Coordination. Defining new supply chain processes across various functions in a matrixed organization necessitates significant coordination, as well as collaboration with commercial teams.

- Digital Enablement. Companies need to understand how advanced digital technologies, such as AI and digital twins, can address the pain points in their supply chain. They must also ensure that the underlying data foundation and pipelines are set up to power the technologies.

- The Need for Speed. Transformations must be completed within one to two years, which demands a rapid and highly efficient mobilization to rework processes, capabilities, and data.

Ensuring That All Functions Pursue a Common Goal

To manage the complexity of an end-to-end supply chain transformation, companies need a blueprint that allows each function to understand the assumptions relating to the transformation that affect it and how its own assumptions affect others. The blueprint should also make dependencies, such as those between distribution and ordering, visible to all participants. This will enable each function to perform its own design, building, and execution in coordination with others.

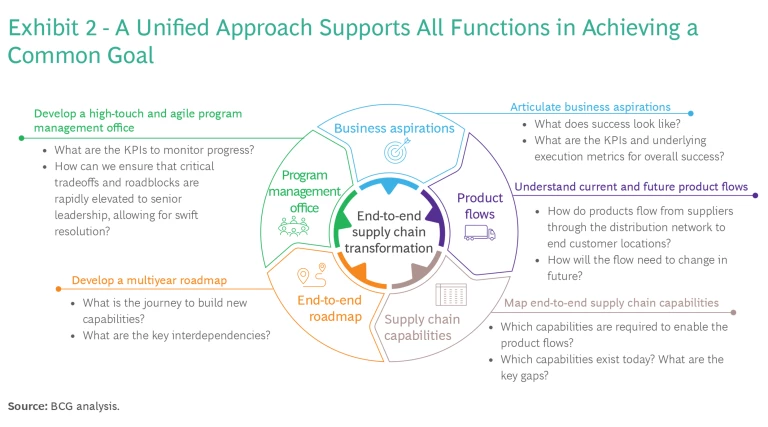

To facilitate the development of this blueprint, BCG has designed an approach composed of five interlocking steps. It ensures coordinated action by providing a strategic and execution roadmap across functions and teams. (See Exhibit 2.)

- Articulate and quantify business aspirations. To guide its efforts, the company must specify what it wants to achieve through the supply chain transformation. It can then determine the KPIs and the underlying execution metrics that contribute to meeting the overall success criteria.

- Understand current and future product flows. The company needs a baseline, granular understanding of how pallets, cases, and individual items flow from suppliers through distribution networks to end customer locations. It uses this information to assess how it must change the product flow to achieve its goals.

- Map end-to-end supply chain capabilities. Understanding product flows allows the company to determine which end-to-end supply chain capabilities it needs today and in the future. It can then pinpoint critical capability gaps and decide how to address them.

- Develop a multiyear capability-building roadmap. The company must determine how to build new capabilities that will enable current and future product flows. This requires identifying which capabilities are prerequisites for others and which ones are critical to completing the transformation.

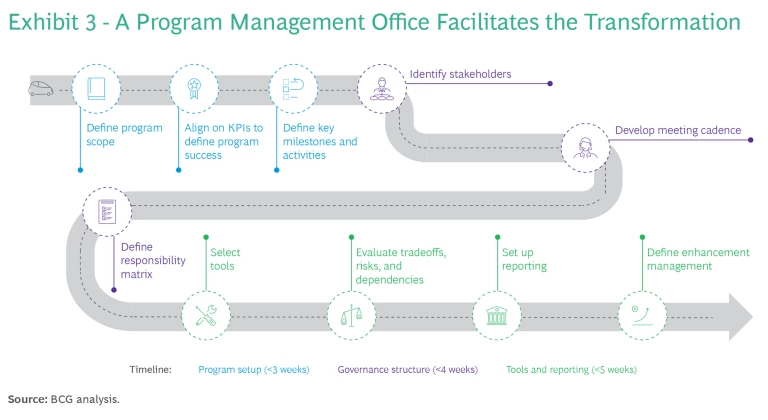

- Establish a high-touch and agile program management office. To support execution, the company needs to appoint a high-touch and agile PMO. (See Exhibit 3.) This body sets up the transformation program, defining KPIs and key milestones. It also creates the governance structure by assigning responsibilities across functions and developing the meeting cadence for evaluating critical tradeoffs and resolving issues. In addition, the PMO establishes tools and reporting formats, including the use of data analytics to enable more effective and agile decision making.

Case Study: Applying the Approach at a Leading Global Retailer

BCG applied this approach to support the end-to-end supply chain transformation of a global retailer. The company’s rapid growth had strained its supply chain and revealed key limitations, especially in cross-functional coordination and data enablement. Finding innovative solutions to these challenges was essential to realizing the company’s ambitious growth plans, including international expansion.

Deploying the Approach

The five-step approach described above provided key insights about the innovations and capabilities required to achieve the company’s goals.

Business Aspirations. We identified increasing revenue by 75% to 100% over the next decade as the primary business aspiration motivating the end-to-end supply chain transformation. We then developed an in-depth understanding of the supply chain implications, including numerical projections for case deliveries, stores in the network, and distribution centers required to service demand. We also identified supply chain innovations needed to achieve these goals, including the introduction of new nodes, such as market distribution centers that stock items closer to the stores and daily multiple deliveries from distribution centers to stores. Other necessary improvements were deploying different truck combinations at different times of day, having drivers manage drops during nonpeak hours, and using customized trucks to co-mingle selected products.

Product Flows. Mapping the end-to-end product flows for the current supply chain helped identify critical gaps. For example, the ordering process lacked essential functionalities for tracking order status, modifying orders, and rerouting orders when necessary. The product flow mapping also highlighted specific shortcomings in the current distribution network that limited its ability to support supply chain innovations.

We then mapped potential future product flows, considering delivery profile (number of drops, time of drop, and volume per drop), location of existing and new nodes (including the possibility of new nodes collocated with existing distribution centers), and type of transportation (including truck size and owned or leased fleets). This assessment helped narrow down the list of key future flows, which facilitated the development of the capability-building roadmap. For the shortlisted flows, we identified the activities needed at each node to realize the envisioned future supply chain.

Supply Chain Capabilities. We mapped each identified activity to an enabling supply chain capability. For example, the company needed an automated order forecasting engine to estimate the next day’s order based on starting inventory, the day’s sales, and heuristics-based forecasts of damaged orders. Such a system can significantly reduce the time that store owners spend placing orders each day.

Some of the key capabilities identified included the following:

- Revamped End-to-End Distribution Network. To support the identified innovations, we proposed investing in new distribution center capacity. This triggered the need to revamp the end-to-end distribution network. Although the new network entailed higher costs and complexity, it gave the retailer greater flexibility and control. The result was higher levels of service and support for product flows than the previous distribution network offered. To initiate implementation, we pinpointed portions of the distribution network that the company could prioritize in the short term and developed a full revamping plan for the long term.

- Digital-First Order Management Platform. The mapping of future product flows revealed that the company needed distributed order management capabilities. These include the ability to add or modify orders, track orders, reroute deliveries to contingent distribution centers in case of disruptions, and track end-to-end inventory. For instance, the company needed the ability to allocate a store owner’s order between the regional and market distribution center on a daily basis, depending on inventory levels at various nodes and delivery times. Recognizing the need for advanced capabilities, the company launched a digital-first order management platform and mobile app to facilitate intuitive and convenient ordering by its store owners.

- End-to-End Data Foundation. A cohesive end-to-end data foundation is a key enabler of a supply chain transformation. Considering future capabilities and product flow requirements, we identified several data gaps relating to, for example, KPIs (such as on-time in-full), end-to-end inventory across nodes, and recommendations for the daily order forecast. To address these gaps, we defined a strategy for capturing the right input data. Steps included requesting data from suppliers, placing GPS devices in trucks, and monitoring and reporting the temperature at distribution centers. We also determined the optimal flow of data to the company’s systems and tools to enable analytics, as well as the channels required to view and monitor output. Further, we supported the company in deploying these strategies, such as by developing and implementing a policy to send and receive key data from suppliers.

A cohesive end-to-end data foundation is a key enabler of a supply chain transformation.

The data strategy and process design are mutually dependent. For example, the company needed end-to-end inventory data to support the daily order forecast. This insight led us to include an inventory module in the digital order management platform and to source the inventory data at stores directly from store owners at regular intervals.

Capability-Building Roadmap. We developed the capability-building roadmap for the next three to five years, including the critical interdependencies across various capabilities.

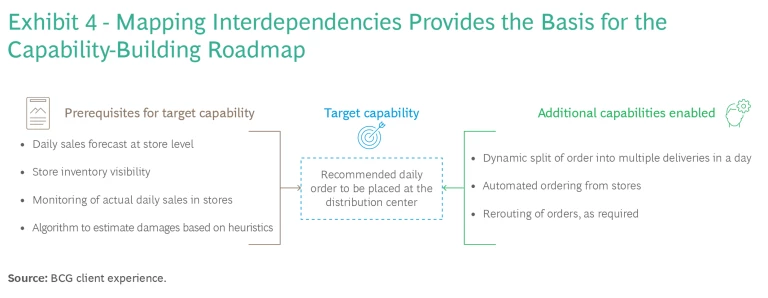

Exhibit 4 illustrates interdependencies relating to the ability to recommend the daily order that store owners should place with the distribution center. The company had to establish four capabilities to enable the daily recommendations. These recommendations, in turn, enable additional capabilities.

Many capabilities necessary to achieve the company’s goal entailed a long chain of interdependencies. Mapping all the capabilities from end to end revealed considerable complexity, necessitating an integrated roadmap to guide the capability-building sequence.

Program Management Office. The PMO facilitated the transformation by addressing several challenges. These included inconsistent ways of working across different teams, the complexity of the resource structure and layers, and an absence of unified incentives. The PMO also significantly streamlined end-to-end execution by developing a weekly meeting cadence for monitoring the most critical KPIs (such as those relating to reducing costs, increasing capacity, and improving quality) using a third-party tracking tool.

Summing Up the Benefits

Since adopting our approach, the company has seen significant improvements in the coordination of design and implementation across functions:

- Alignment on Success Goals. Leaders and their teams understand the key overall goals and how they relate to their own project goals and objectives over three to five years.

- Clear Understanding of Broader Integration. Functional leaders understand how their initiatives fits into the broader initiative, ensuring clear coordination with both upstream and downstream processes and solutions.

- Efficiency and Accountability. The approach has helped to reduce duplicative work and clarified ownership and accountability, streamlining the overall process.

BCG’s innovative transformation approach offers an integrative blueprint for companies seeking to fortify and streamline their supply chain processes. The approach emphasizes the importance of coordination, digital enablement, and speed. Recent successes highlight its efficacy in harmonizing disparate elements, fostering cross-functional alignment, and driving end-to-end transformation. By adopting such a comprehensive strategy, companies can navigate the challenges of supply chain transformation more effectively, thereby setting the foundation for long-term enterprise growth.