This is a modal window.

Shipping route disruptions such as the Suez Canal blockage in 2021 and the Panama Canal’s low water levels in 2024. Acts of piracy that have forced the rerouting of cargo away from a major Red Sea shipping route. Geopolitical turmoil linked to the war in Ukraine. Persistent shortages of materials including critical microchips.

These and other events have snarled the supply chains of companies in energy, construction, and other heavy industries in recent years.

Such companies have found it difficult to prepare for the severe supply chain disruptions these black swan events caused. At the same time, they have also had to contend with the increasing levels of “normal” volatility that ripple through their interconnected supply chains because of demand uncertainty, shifts in production asset outputs, and supply delays.

Part of the challenge is that industrial supply chains have grown increasingly complex and hard to manage. Recent BCG research has found that executives and managers overseeing industrial supply chains are grappling with four key pain points that can carry high costs and heavy risks:

- Siloed, incomplete, and inaccurate data that forces people to make decisions in isolation without seeing the whole picture

- Intermittent and reactive analysis that requires supply chain leaders to respond to disruptions instead of anticipating them and figuring out how to capture future high-value opportunities

- Manual processes and bottlenecks that lead people to spend too much time on low-value activities rather than focusing on the actions and issues that matter most to the business

- Insufficient user engagement with complex and unintuitive tools, resulting in manual workarounds that hinder transparency and prevent efficient collaboration

To address these challenges, many industrial players with complex supply chains (for example, companies in the oil and gas, renewables, chemicals, steel, and mining industries) are turning to digital twins : virtual replicas of their end-to-end supply chains, with AI, simulation, and scenario-planning capabilities.

The Rise of Digital Twins

Companies use digital twins to anticipate and mitigate risk, predict bottlenecks, find the right supply and inventory buffers, better manage their supplier base and contracting processes, maintain required capacity, and even optimize their ability to capture sales. Digital twin technologies allow companies to reduce inventory and capex, improve EBITDA and costs, increase throughput, reduce risk, predict delays, and raise service levels.

In fact, some organizations are now adopting a digital-first mindset where they think in terms of digital originals and physical twins. Instead of building a new physical factory or extending supply chains and then simulating them in a digital space, these companies are designing and optimizing virtual systems in the digital realm and then creating equivalents in the physical world. This digital-first approach seems likely to become more prevalent as AI and simulation capabilities grow more powerful and companies begin to take a more sophisticated systems approach to implementing digital twins.

Introducing Value Chain Digital Twin by BCG X

Digital twins and digital-first approaches help industrial firms to alleviate supply chain pain points. Digital twin solutions can deliver even more benefits with a systems approach that connects individual technologies and use cases to optimize supply chains end to end.

Value Chain Digital Twin by BCG X is a client-centric offering that applies this systems approach through customizable solutions, technology-agnostic architecture design, and business-centric deployment centered on value delivery. This advanced platform allows clients to build on their existing achievements and expand their digital capabilities toward a full digital twin.

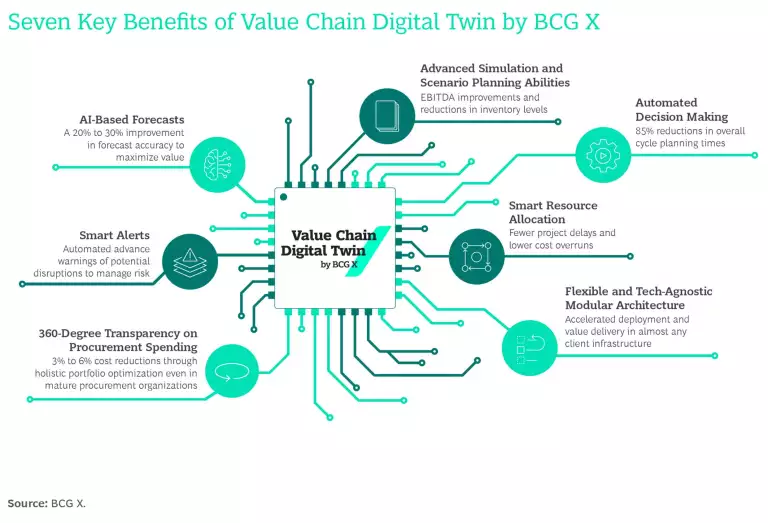

Leading companies have already begun to experience major business benefits from Value Chain Digital Twin’s features.

- AI-based, probabilistic forecasts help companies improve planning accuracy, mitigate risk, and assess the impact of disruptions on their supply chains. Value Chain Digital Twin by BCG X provides the ability to combine internal data such as historical demand patterns, supply performance, inventory draws, and short-term consumption changes with external data including industry indices, port utilization, and shipping volumes. By deploying advanced AI on these interdependent factors, companies can automatically forecast demand and analyze supply patterns at higher accuracy as well as to identify risks weeks and months in advance. Early adopters of Value Chain Digital Twin have seen benefits such as 20% to 30% improvement in forecast accuracy, full coverage of the long tail in planning, and 50% to 80% reductions in delays and downtime.

- Smart alerts provide early warnings of potential supply chain disruptions so that companies can take preventive action. Value Chain Digital Twin gives companies end-to-end transparency into both internal and third-party supply chains. By continuously evaluating variables such as material flows and demand fluctuations and simulating the potential outcomes, Value Chain Digital Twin can spot possible supply chain disruptions, prioritize them, and automatically issue alerts so that companies can act more quickly than they do when relying on manual processes.

- Companies gain 360-degree transparency into the procurement spending base. Value Chain Digital Twin allows companies to optimize their category management and buying through automated identification of optimization areas, as well as evaluation of drivers like price indices, competitive supply situation, and cross-supplier and material interdependencies. Because assessment, monitoring, and focus setting are mainly automated, procurement managers and buyers can focus on the areas that really matter and holistically optimize their portfolios. This allows for effective supplier portfolios as well as deliberate tradeoffs between cost, inventory, risk, and carbon footprint. Thanks to this advanced decision support, Value Chain Digital Twin has delivered cost reductions of 3% to 6% even in mature procurement organizations.

- Advanced simulation capabilities for improved scenario planning to help mitigate supply chain volatility. One steel manufacturer used Value Chain Digital Twin’s simulation capabilities to assess the interdependencies of demand, supply, and production volatility in order to evaluate the likelihood of disruption in a virtual environment that replicated the company’s interconnected supply chain, which included 50 producing assets, 300-plus warehouses, and more than 20,000 SKUs. By using the simulation to anticipate risks up to 12 weeks in advance, the manufacturer was able to identify and implement alternative production and delivery plans to improve EBITDA by 2 percentage points while reducing inventory levels by 15%.

- Automated decision making allows teams to focus their time and energy on areas where expertise can add the most value. For instance, Value Chain Digital Twin analyzes internal and external indicators such as shifts in demand and commodity prices that procurement teams can use to support buying decisions and negotiations with supply chain partners. In one case, Value Chain Digital Twin enabled a procurement team to automate 85% of its planning activities. Tasks that previously took days to complete were now automated and executed in minutes, which helped the company cut its overall cycle planning times by 50%.

- Smart allocation of resources helps companies maximize value. Value Chain Digital Twin analyzes and simulates the interdependencies of multiple variables so that companies can dynamically set and adjust buffers to minimize the cost and impact of any supply chain disruptions. We recently used Value Chain Digital Twin to help a renewable energy firm maximize the value of a capital project by optimizing buffers for its inbound supply chain in order to reduce project delays and limit cost overruns.

- Impact can be achieved rapidly and seamlessly in practically any client infrastructure because of the tech-agnostic architecture. The flexible, modular, and fully customizable nature of Value Chain Digital Twin enables companies to implement its capabilities incrementally on their tech infrastructure while working to achieve a broader strategic vision. This incremental architecture accelerates value delivery in a wide variety of industries, companies, and IT environments. For example, one client wanted to access Value Chain Digital Twin’s forecasting and automated decision support tools while retaining its existing cloud infrastructure and basic planning workflow. To do this, Value Chain Digital Twin was deployed on top of the company’s basic planning infrastructure in SAP and established automated data transfers to the cloud environment; with this approach, the client could start seeing benefits from Value Chain Digital Twin within three months after the engagement began.

An Intuitive Approach to Gaining End-to-End Control of the Supply Chain

In BCG X ’s experience supporting leading companies on their digital journeys, technological solutions add value only when they see high adoption rates and get used as intended. That’s why Value Chain Digital Twin was designed to provide an intuitive and natural user experience. As a result, Supply Chain and Procurement teams feel comfortable using the platform to collaborate on high-value tasks.

Instead of asking users to decipher data tables and endless reports, Value Chain Digital Twin prompts them to focus on key business decisions, issues alerts regarding potentially serious risks, and highlights the areas that could add the most value. By replicating businesses processes, Value Chain Digital Twin capabilities fit into the supply chain workflow and support integrated collaboration throughout organizations.

In these ways, Value Chain Digital Twin can improve procurement decision making, mitigate supply chain risks, and deliver significant cost reductions while improving operational efficiency.