The global rail industry stands at a pivotal juncture. As urban populations swell and environmental concerns intensify, rail transport is increasingly viewed as a sustainable alternative to road and air travel. However, rail operators and infrastructure managers face a host of challenges that impede efforts to meet rising demand efficiently and effectively.

The road forward lies in embracing fully digitized, seamlessly connected rail operations. (See “The Rail Industry’s Challenges Demand Digitization.”) By leveraging advanced technologies and fostering collaboration, the industry can enhance efficiency, improve service quality, and meet customers’ evolving expectations.

The Rail Industry’s Challenges Demand Digitization

The Rail Industry’s Challenges Demand Digitization

- Modal Competition. Rail players must help develop and implement digital innovations in order to close the gap with more technologically advanced modes of transport, such as road and air travel.

- Fragmented Collaboration. Conflicting interests, siloed processes, and legacy tools complicate coordination among infrastructure managers, freight and passenger rail operators, and other stakeholders.

- Capacity Constraints. Conventional methods of managing rail capacity cannot keep pace with surging demand driven by higher levels of maintenance, construction, and traffic, leading to capacity shortages.

- Customer Expectations. Freight clients and passengers increasingly demand greater flexibility and transparency, stretching fragmented systems and siloed operations to their limits.

- Market Liberalization. Ongoing deregulation and evolving market dynamics are compelling industry players to explore new revenue streams and business models.

- Regulatory Pressures. Operators and infrastructure managers must modernize systems, standardize interfaces, and share data—which is often trapped in legacy systems—to comply with new legislative requirements, such as accurate and transparent planning. For example, Annex VII of the European Union’s railway regulations mandates that infrastructure managers consult early with operators when planning track closures in order to provide transparency about potential disruptions.

- Rising Investment Needs. Shorter innovation cycles require substantial upfront investment, intensifying financial pressures and prompting questions about viable and sustainable financing strategies.

The Vision of Full Digitization

Envision a rail ecosystem in which all the components—from infrastructure and rolling stock to personnel and passengers—are interconnected through a seamless digital network. Such a fully digitized and integrated system will break down silos, streamline processes, and foster real-time collaboration among infrastructure managers, rail operators, and customers. It will address the industry’s pain points by transforming how rail services are planned, executed, and experienced. And it will harness the power of data analytics , automation, and advanced communication tools to optimize capacity management, improve maintenance, and elevate both passenger and freight services.

For instance, predictive maintenance powered by real-time data can preempt equipment failures, reducing downtime and maintenance costs. Integrated capacity planning can optimize timetables and resource allocation, minimizing delays and congestion. Enhanced customer information systems can provide real-time updates, improving customer satisfaction and loyalty.

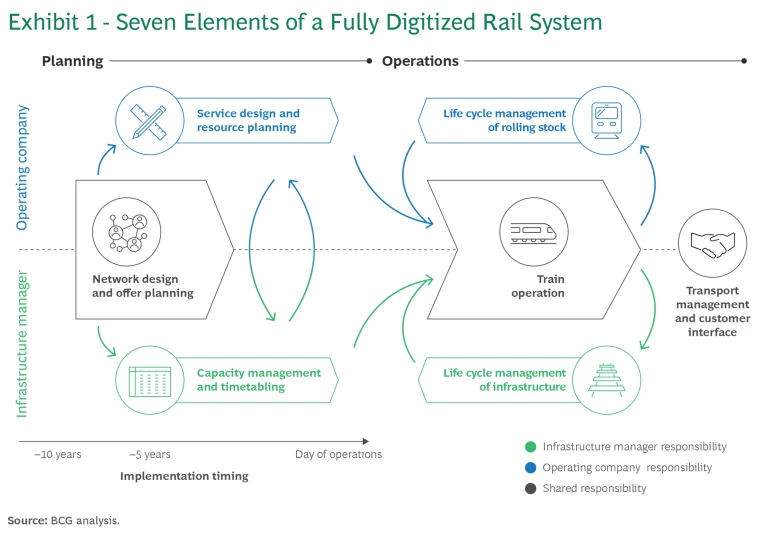

This vision for an improved rail system is not just about technological advancement. It reimagines the industry to become more responsive, efficient, and customer-centric. To realize this vision and overcome the challenges that stand in its way, rail operators and infrastructure managers must collectively focus on seven specific aspects of planning and operations that, when integrated, will result in a cohesive system that sets a new standard for rail transportation. (See Exhibit 1.)

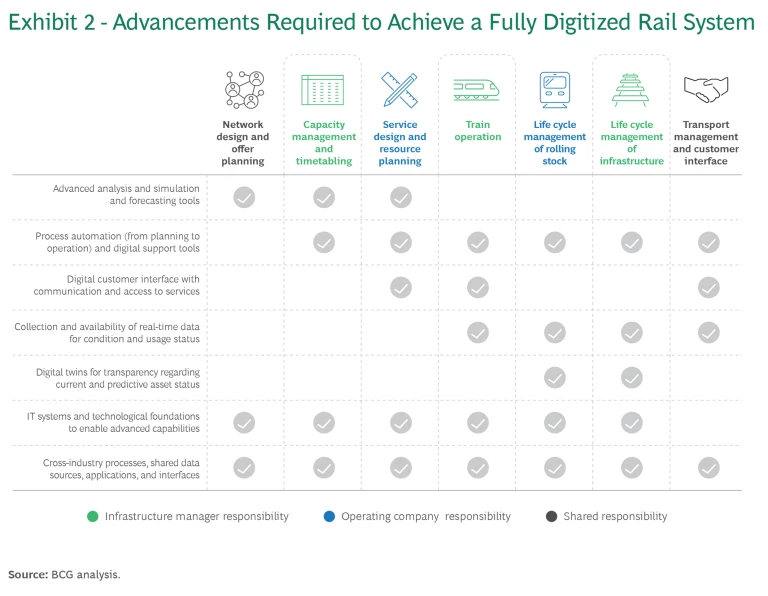

Planning begins ten years before train operations commence, while life cycle management continues throughout operations, underscoring the long-term commitment required to achieve this transformation. Comprehensive advancements in technology, processes, and collaboration are required across all phases of the planning and operations life cycle. (See Exhibit 2.)

Network Design and Offer Planning

The first step is to define the future rail network and service offering. Governments, rail infrastructure managers, and operating companies already participate in this process to varying degrees depending on the market. The aim is to develop a compelling offering while optimizing the long-term use of operational resources in alignment with desired service levels. This requires integrated capacity planning to balance supply and demand. It allows rail operators and infrastructure managers to ensure that capacity constraints do not hinder service delivery and that future demand is anticipated and efficiently met.

Network design also involves establishing the technological standards for the infrastructure , including traffic management systems (for example, the European Rail Traffic Management System), train control systems (for example, the European Train Control System and communications-based train control), interlocking systems, and communication technologies (for example, the Global System for Global Communications—Railway and the Future Railway Mobile Communications System). It also sets the technological requirements for operating companies, such as support for automated operations, digital coupling of vehicles (for example, digital automatic coupling), and other innovations that enhance efficiency and integration.

Ideally, a collaborative process for long-term capacity planning provides an integrated and consistent view of capacity requirements, with continuously refined forecasts. This process covers passenger demand, which is relatively predictable, as well as the needs of large rail freight customers—including potential structural changes. Infrastructure capacity planning considers planned construction projects and maintenance schedules, while aligning train and personnel resources with operational requirements. This unified approach enables proactive adjustments and investments, ensuring that the rail network can accommodate growth and evolving service demands.

To enable automated train operations, major traffic routes must be equipped with advanced traffic management systems, combining sophisticated train control systems and a robust communications infrastructure. Trains operating on these routes will have onboard monitoring units and auxiliary systems, such as digital automatic coupling for freight cars, to ensure train integrity.

Capacity Management and Timetabling

Capacity management and timetabling focus on the efficient and effective use of infrastructure for operations as well as for maintenance and construction activities. By optimizing the timetable across all planning horizons, the system ensures that infrastructure is fully utilized while maintaining alignment with operational needs. This approach enhances transparency and information quality for railway operators, reduces peak-load pressures, and improves punctuality—all without compromising traffic volume.

In a fully digitized rail system, capacity management and timetabling are integrated across all time horizons and sometimes across small localities and neighboring countries as well. Infrastructure managers provide transparency regarding anticipated restrictions, which operators need for effective planning. Advanced and standardized automation supports planners in generating optimized solutions for the entire network. Simulation tools facilitate detailed impact analyses of changes, aiding dispatching and partially automating timetable creation—and ultimately strengthening the system’s timetabling scheme.

A fully digitized customer interface streamlines the process of purchasing train paths, enabling operators to request network capacity as needed rather than booking paths far in advance. Decisions about such requests are data-driven and automated, providing operators with real-time feedback.

Service Design and Resource Planning

Operating companies must offer services that meet customer expectations while optimizing the use of resources such as rolling stock, depots, and personnel. The aim is to design services that are attractive and reliable for passengers and freight customers as well as operationally efficient and profitable. This allows companies to ensure that their offerings continue to be competitive and to meet customer expectations.

Envision a rail ecosystem in which all the components are interconnected through a seamless digital network.

In the envisioned rail system, advanced planning systems integrate service design, train rotations and downtimes, and resource allocation. Digital systems provide real-time access to capacity demand and bookings. For rail freight, a digital interface enables customers to book capacity, while ad-hoc requests are simulated to assess feasibility. Similarly, for passenger rail, demand simulations based on traffic flows ensure proactive resource planning. Digital twins of individual trains offer real-time insight into the current and future state of assets and the downtimes required for maintenance.

Train operators’ systems are equipped with standardized interfaces that connect directly to infrastructure managers’ systems. This gives operators real-time visibility into planned restrictions on specific days and the ability to quickly request train paths as needed. High levels of automation streamline planning, supported by the computing power and advanced analytical capabilities required to enable complex simulations in a variable-rich environment. These tools allow operators to optimize planning through simulations of scenarios in which, for example, cost efficiency, maximum fulfillment of customer requirements, or the highest levels of resilience and punctuality are achieved. Operators are empowered to make informed, data-driven decisions that enhance operational efficiency.

Train Operations

In a fully digitized rail system, train drivers, dispatchers, and operations controllers have access to up-to-date digital timetables on their devices. Trains are equipped with tracking technology and Internet of Things sensors, which provide real-time data on train conditions (for example, technical status and occupancy levels) and infrastructure conditions (for example, video footage of tracks and onboard measurements). Similarly, infrastructure is digitally connected, delivering critical insights into its usage and status (such as technical conditions and load) and the conditions of passing trains (such as wheelset profiles and sound patterns). This wealth of data forms the basis for intelligent real-time dispatching systems and serves as input for short-term planning tools.

An interface between the systems of the infrastructure manager and the operator supports assisted or automated decision making. Information on traffic changes is automatically distributed to related systems and processes—such as asset and personnel planning, dispatching, and billing—triggering any necessary adjustments.

In highly congested areas, train control is primarily automated, utilizing state-of-the-art communications-based train control systems. This integration of technology ensures smoother operations and fewer disruptions with less impact. The systems simulate the second- and third-order effects of a disruption, such as cascading delays or passenger flow bottlenecks. With this enhanced understanding, operators can implement optimized responses—such as dynamically reallocating trains or adjusting service patterns—to ensure faster recovery and minimize the impact on overall network performance.

Life Cycle Management of Rolling Stock

Operators need to maximize vehicle availability, reduce maintenance costs, and improve maintenance quality to prevent technical failures and service disruptions. This ensures that rolling stock is reliable, safe, and meets operational demands.

In the envisioned system, rolling-stock maintenance is extensively digitized, transitioning from traditional interval-based schedules to predictive maintenance. This shift is powered by real-time sensor data on rolling-stock condition—collected before, during, and after train operations—combined with advanced analytics. Digital twins of individual assets provide up-to-the-minute insights, enabling automated dispatching decisions and precise scheduling of downtime and maintenance activities.

Depot operations are largely automated, with work planning dynamically adjusted based on current asset demand, the status of individual vehicles, and available depot capacity.

Maintenance staff

are equipped with advanced digital tools, such as augmented-reality glasses and handheld devices, which provide instant access to digital manuals and repair procedures. Proactive procurement strategies further enhance efficiency by optimizing the total cost of ownership over the lifespan of the assets.

Life Cycle Management of Infrastructure

Infrastructure managers need to maximize their network’s availability today while maintaining and upgrading it to ensure sufficient capacity for long-term growth. Focusing on these two requirements enhances infrastructure reliability, minimizes disruptions, and supports the increasing demands on rail networks. New technological standards defined during network design support this management process.

A fully digitized and integrated system will break down silos, streamline processes, and foster real-time collaboration among infrastructure managers, rail operators, and customers.

Infrastructure maintenance in the new rail system is extensively digitized. Predictive-maintenance schemes, powered by data from wayside sensors, on-train measurements, visual inspections, and drones, for example, ensure timely interventions. Analytics plays a pivotal role in interpreting this data.

To minimize capacity disruptions, maintenance and construction activities are bundled by time and location. Digital applications support staff throughout the maintenance and construction planning and execution processes, enhancing efficiency and reducing the potential for human error. Just as for rolling stock, integrated digital twins provide a holistic, real-time view of the infrastructure. The information is fed into predictive maintenance and digital construction planning, enabling smarter decisions and seamless upgrades. Intelligent maintenance and systematic infrastructure expansion increase rail capacity while meeting higher traffic volumes.

Transport Management and Customer Interface

Transport management and the customer interface enhance the customer experience by providing timely and accurate information, proactively managing passenger and freight flows, and improving operational efficiency.

In a digitized system, passengers receive timely travel information through analog and digital channels, which guide them to platforms and trains and improve the onboard experience. For freight customers, real-time tracking provides end-to-end visibility of shipments, including forecasts of delivery times and potential delays.

Six Imperatives for Realizing the Vision

Six imperatives for rail operators and infrastructure managers will drive the transition.

- Accelerate the adoption of new technologies. Emerging technologies—such as communications-based train control systems (for example, the European Train Control System and the Chinese Train Control System), digital automatic coupling, and communications standards (for example, the Future Railway Mobile Communications System)—form the basis for a fully digitized and integrated rail operation. Fast-tracking their planning and implementation is essential to unlocking future benefits.

- Utilize real-time data and automation. As transformative train control technologies are being implemented, real-time tracking and status data offer substantial opportunities to boost operational efficiency and effectiveness. As real-time data becomes more widely available, the scope of automation continues to grow. To fully capitalize on these advances, a robust IT and data infrastructure is indispensable, forming the backbone of a more efficient and responsive rail operation.

- Develop digital twins of rail assets. Rail systems involve complex interactions among various assets and components. Creating digital twins of physical assets allows this complexity to be captured and processed digitally. An initial application of digital twins is enabling predictive maintenance, which uses real-time data to reduce unplanned outages, streamline maintenance schedules, and minimize disruptions.

- Implement integrated digital systems. Integrated systems for planning, dispatching, and capacity management are essential. These must also include end-to-end integration of core processes—such as order to cash and procure to pay—that connect with clients, suppliers, and stakeholders beyond core rail operations. By optimizing resources, enhancing transparency, and aligning the operational plans of operators and infrastructure managers, these systems foster coordination and efficiency.

- Enhance the customer experience with data-driven solutions. Rail systems should employ advanced analytics and smart technologies to manage passenger flow, refine service offerings, and provide end-to-end freight visibility. These data-driven solutions help to ensure a seamless and efficient customer experience.

- Foster collaboration and data sharing. Transparent data sharing and interoperable systems are critical to enabling joint planning, improving coordination, and ensuring that the rail ecosystem evolves to meet future service demands.

Digitization accelerates the shift to a greener transportation ecosystem by making rail systems more competitive with other modes of transport. Rail operating companies and infrastructure managers can unlock transformative potential by tackling challenges such as fragmentation, inefficiency, and outdated practices. Success requires adopting advanced technologies, fostering collaboration, and prioritizing customer-centric approaches. By committing to a shared vision, industry stakeholders can create reliable, efficient rail systems that serve as the foundation of sustainable transportation.