Companies have already taken steps to reduce costs along the supply chain. Further reductions require tougher decisions in several key areas.

Featured Insights

Supply Chain Management

Video

January 10, 2025

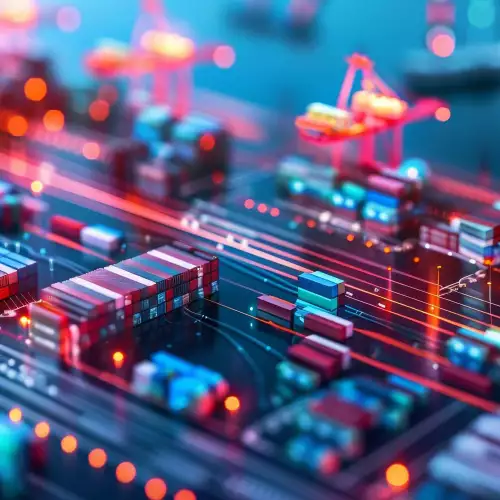

Staying Ahead of Trends in Global Trade

Geopolitics is escalating already seismic shifts in global trade. As trade lanes evolve, consider shifting your supply chains to make them more robust, cost effective, and resilient.

Article

February 6, 2024

With parallels to the complexities of building a house, BCG’s approach to transforming a supply chain emphasizes the importance of coordination, digital enablement, and speed.

Article

August 7, 2024

Costs are threatening the ability of process companies to take advantage of both organic and inorganic growth opportunities because of expanding financial constraints.

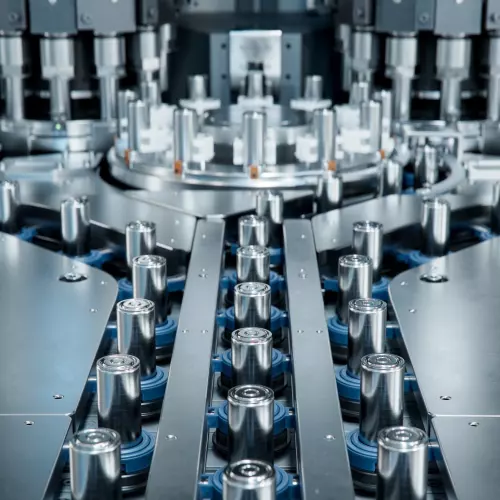

BCG-WEF Project: AI-Powered Industrial Operations

How can manufacturers harness the latest technologies to optimize for increased productivity, improved sustainability, greater resilience, and a stronger workforce?

Procurement

Video

January 27, 2025

The Cost-Saving Power in Procurement

Declining producer prices have given process industry firms a crucial but limited window of opportunity to renegotiate contracts and set a new cost baseline.

Article

September 25, 2024

As the global business landscape grows more complex and politically fraught, companies are struggling to balance cost reduction, supply chain resilience, and access to key markets.

Article

February 13, 2024

Companies can use a category-specific analysis to identify the best alternatives to conventional sourcing strategies.

Article

September 25, 2023

Collaboration and digital technology are the keys to overcoming the main challenges of supply chain risk management.

BCG Executive Perspectives: The CEO’s Dilemma

In this series, we examine the disruptive forces that are bearing down on business leaders today, so that they can understand where opportunities exist amid the uncertainty.

Manufacturing

Slideshow

August 23, 2023

Advanced manufacturers lead their peers across six key attributes, particularly in embedding AI into their operations. This is the factory of the future.

Article

September 21, 2023

Trade disruptions have prompted many global companies to shift where they produce and source goods. But getting the desired results requires a difficult balancing act.

Video

January 25, 2024

Amid shifting dynamics, transforming the global footprint can improve companies’ resilience and sustainability and cut manufacturing and supply chain costs. How are successful companies doing it?

Article

July 13, 2023

By applying levers that reduce both carbon emissions and costs, industrial companies can generate savings to invest in further decarbonization initiatives.

Service & Support

Article

February 18, 2025

Companies that prioritize selling aftermarket services to supplement equipment sales not only generate much more income, they also solidify lasting relationships with customers.

Video

December 6, 2024

Companies Can Generate Value by Improving Their Data

Dealing with data quality issues at the source lets businesses start with a strong foundation and make the most of GenAI, DQC’s Michael Spira explains.

Article

September 6, 2024

Customer service organizations will not achieve their ambitious goals for generative AI – in terms of quality and efficiency – unless they transform their operating model.

Article

December 12, 2023

Reaching a higher, value-adding level of support function maturity isn’t a distant vision but a tangible goal that can be achieved with purposeful action.

We're on LinkedIn

Follow BCG's Operations practice on LinkedIn for the latest operations insights and news across all aspects of the product journey.

Capital Project Management

Video

July 14, 2020

Secrets Behind Successful Large Capex Projects

To keep projects on track, managers must excel on multiple fronts–including fostering transparency into project challenges, encouraging collaboration among all stakeholders, and candidly assessing project risks.

Video

July 14, 2020

Think Big

Behind “think big” is transparency and collaboration. That’s how BCG conceives a successful large capital project. Let’s think big to make big things happen.

In a turbulent, fast-changing world, innovation success means getting it right over and over again.

Subscribe to our Operations E-Alert.

Operational Excellence

Report

November 18, 2024

BCG research reveals what sets a select group of leaders apart. Here's how to join them.

Article

February 22, 2024

Organizations’ biggest cost is usually operations, making it the first place to seek efficiency and productivity improvements to fund the future.

Slideshow

September 25, 2023

Organization-wide platforms for product and service delivery enable agile ways of working and rapid recovery from crisis.

Article

November 21, 2022

BCG’s new benchmark reveals that only 10% of companies are truly prepared for supply chain disruptions. Where does your company stand?